Tyre tread pattern structure for engine driven two-wheel vehicle

A technology for motorized two-wheeled vehicles and tread patterns, applied to tire treads/tread patterns, tire parts, vehicle components, etc. Rigidity and other issues to achieve the effect of improving wet grip performance, improving grip performance, and ensuring tread rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

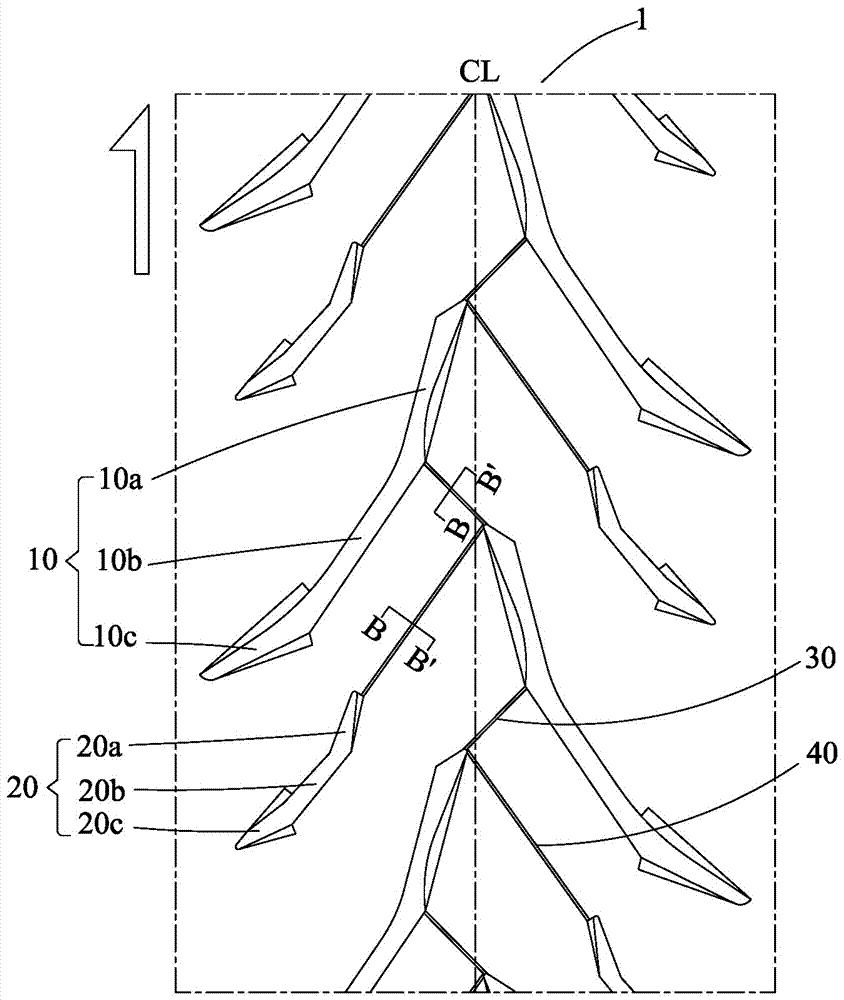

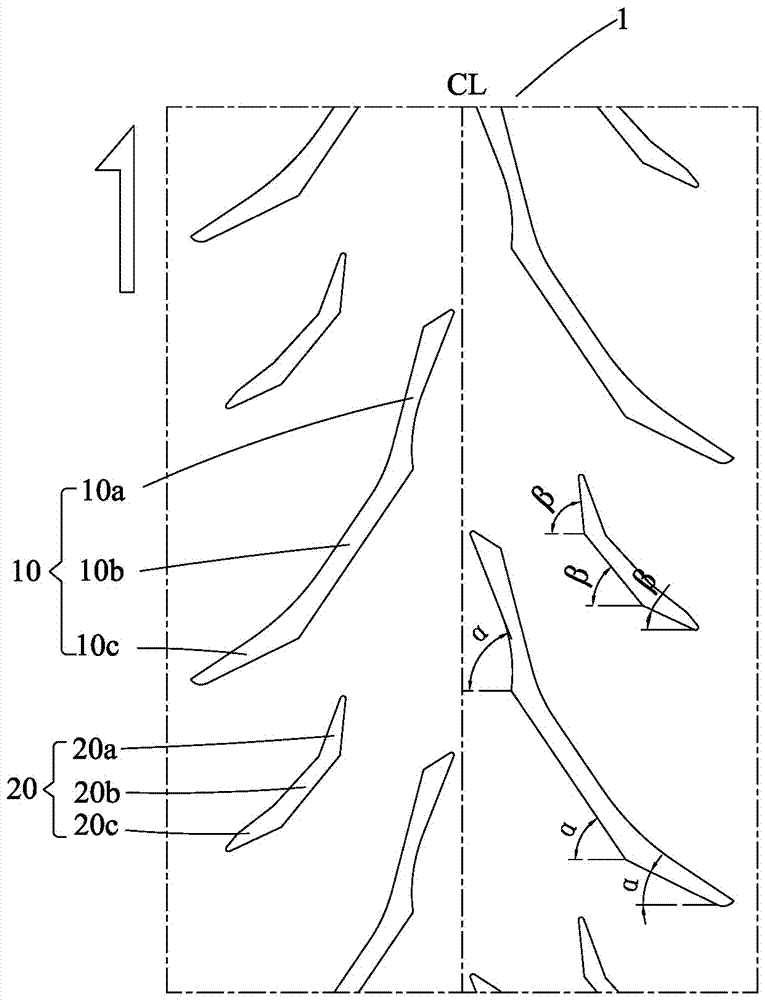

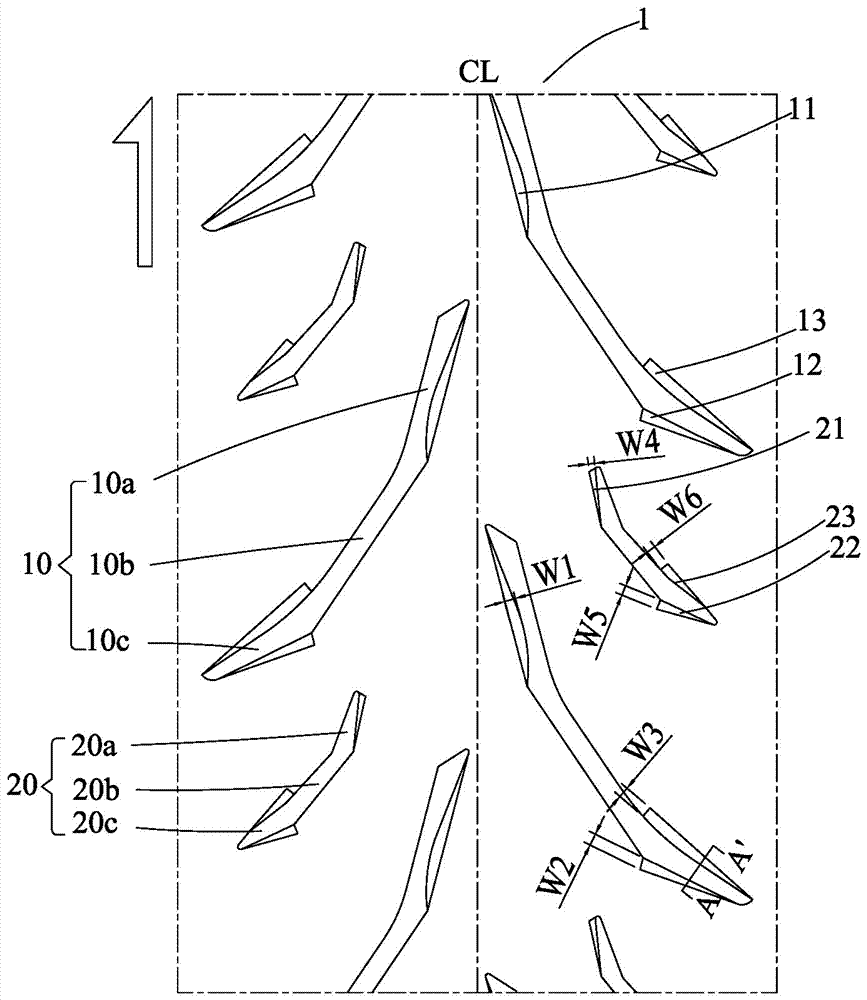

[0023] Such as Figure 1 to Figure 5 As shown, the present invention discloses a pneumatic tire tread pattern structure for two-wheeled motor vehicles. The transverse direction is the tire axial direction, the vertical direction is the tire circumferential direction, CL is the equatorial plane, and the arrow points to the tire driving direction.

[0024] Cooperate figure 2 As shown, the tire tread 1 is composed of several pattern units arranged symmetrically and staggered along the equatorial plane of the tire. Each pattern unit includes a main groove 10 and a secondary groove 20. The main groove 10 is inclined from the equatorial plane to the shoulder Extends and is composed of a first main groove 10a close to the equatorial plane, a third main groove 10c close to the shoulder, and a second main groove 10b connecting the first main groove 10a and the third main groove 10c, wherein The main grooves and the axial inclination angle α from near the equatorial plane to the shoulder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com