Small explosive roll loading and clamping machine

A medicine roll and card machine technology, which is applied to conveyor objects, transportation and packaging, packaging, etc., can solve the problems of not meeting the requirements of reducing people and automation, reducing production efficiency, and increasing the number of operators, achieving low cost and improving work efficiency. , reduce the effect of the operator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

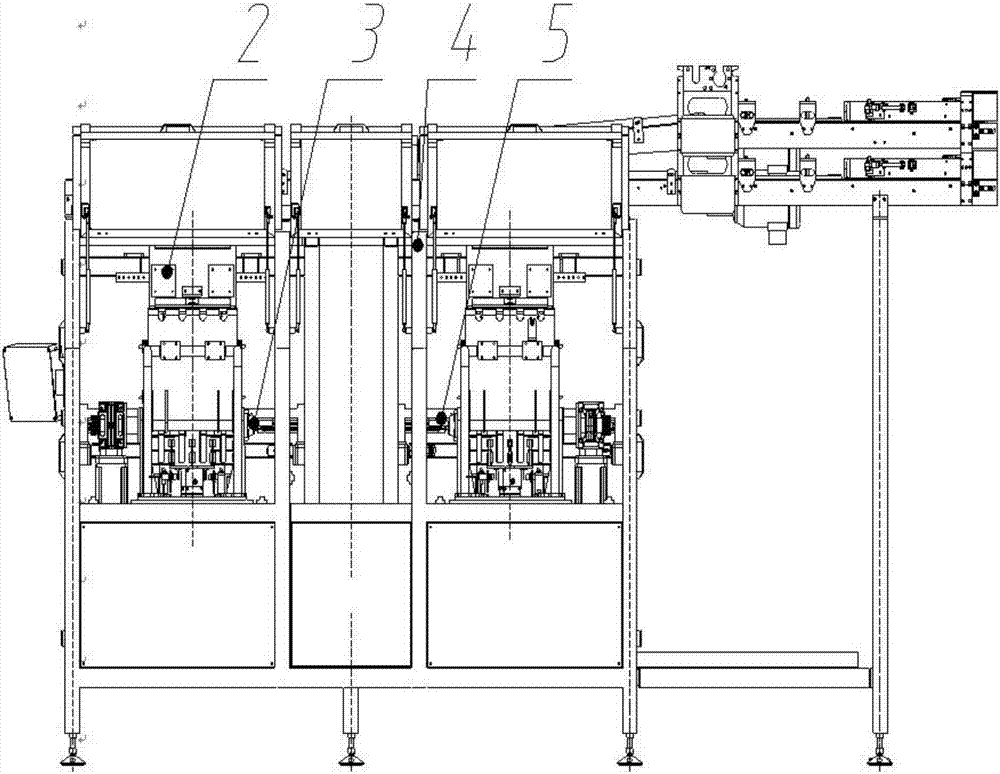

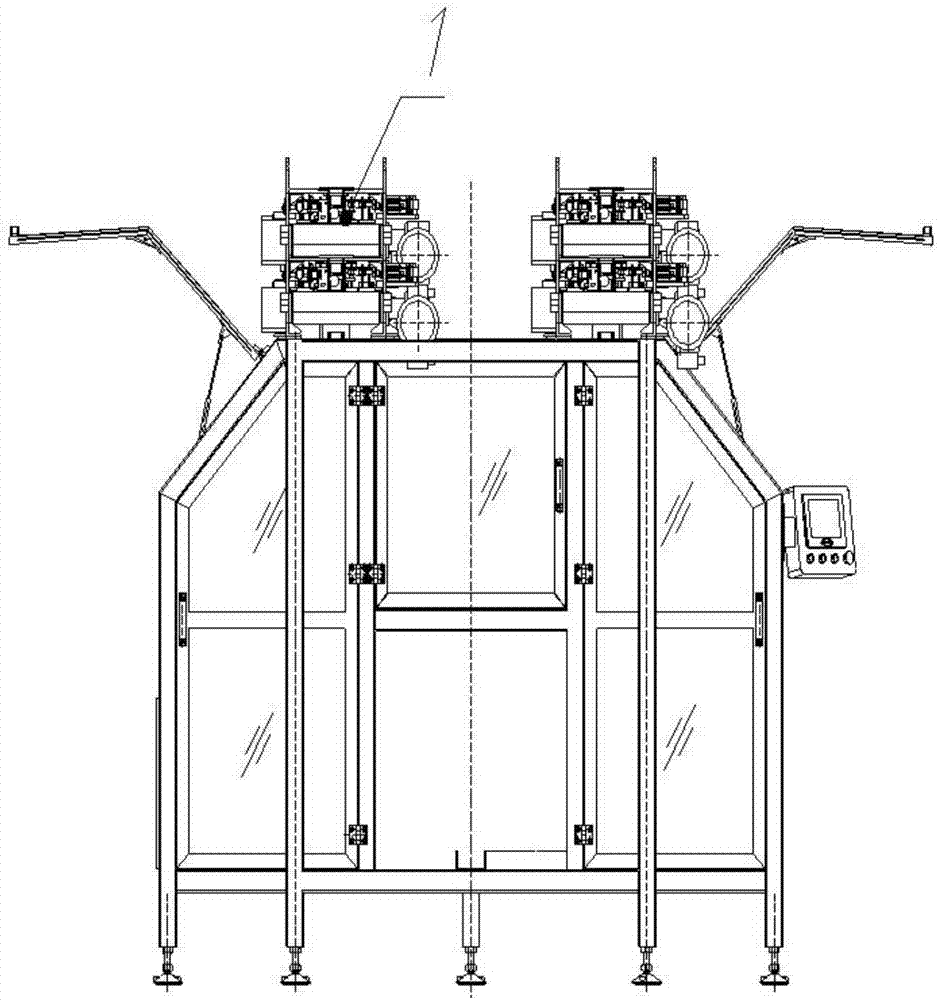

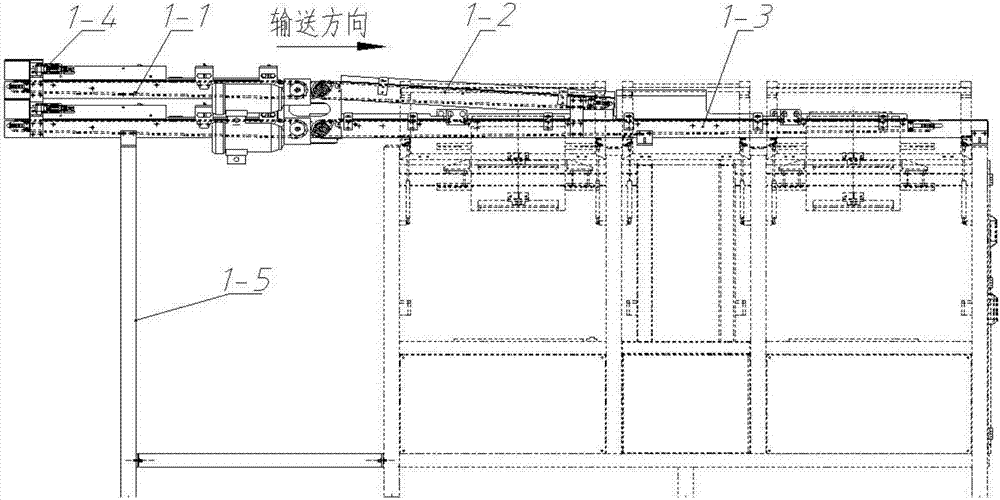

[0039] refer to Figure 1 to Figure 11 As shown, the small medicine roll card loading machine in an embodiment provided by the present invention includes a frame part 4, and a sorting part 1, a transition device 2, an arrangement device 3 and The pumping part 5, the output end of the sorting part 1 is connected with the input end of the transition device 2, the output end of the transition device 2 is connected with the input end of the arrangement device 3, and the output end of the arrangement device 3 is connected with the input end of the pumping part 5 Realize that the medicine rolls are automatically adjusted, transitional buffered and arranged, so that the medicine rolls are arranged in the form of a tuck, and prepare for the subsequent code card tuck (the specific embodiment of the Chinese medicine roll forms a tuck specification according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com