Loading equipment and material loading method

A technology for loading equipment and materials, applied in the direction of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of insufficient loading speed, low labor efficiency, and large impact, and achieve improved material placement accuracy and automation The effect of improving and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Example embodiments are described more fully with reference to the accompanying drawings.

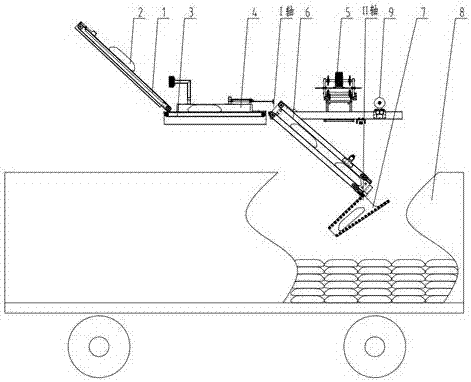

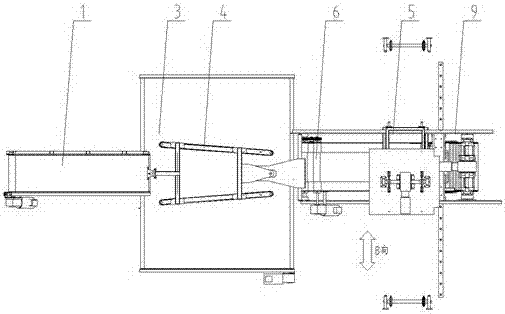

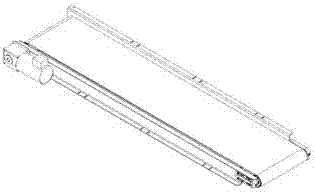

[0039] Such as Figure 1-2 As shown, a front view and a top view of a loading device according to an embodiment are shown, and the loading device mainly includes a feeding conveying device 1 (such as image 3 shown), the first conveying equipment 3 (such as Figure 4 shown), the second conveying equipment 6 (such as Figure 5 shown), the third conveying equipment 7 (such as Figure 5 shown), and redirection limit device 4. The bagged materials 2 (such as cement bags, food bags, sandbags, etc.) are first placed on the feeding conveying device 1 . The feeding conveying device 1 is connected to one end of the first conveying device 3 . The first conveying device 3 and the second conveying device 6 and the third conveying device mentioned later all include two ends, wherein the end near the left shown in the drawings is the first end and the end near the right It is the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com