Bending deformation controllable steel rail online overall wind spraying quenching simulation experiment device

A technology for simulating experimental equipment and bending deformation, applied in quenching equipment, heat treatment process control, furnace type and other directions, can solve the problems of high energy and time consumption, adjustment of spray parameters, low efficiency, etc., to achieve high spray pressure, reduce The effect of the cost of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

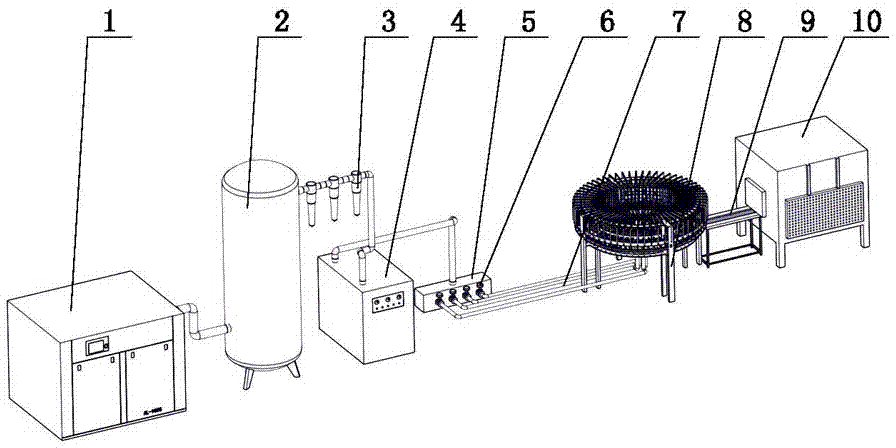

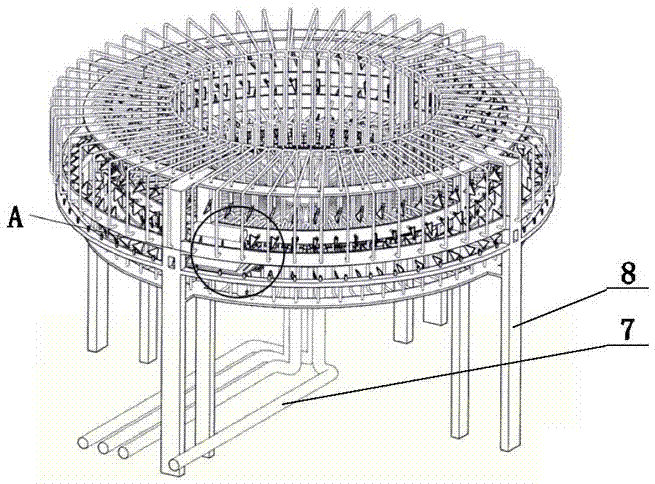

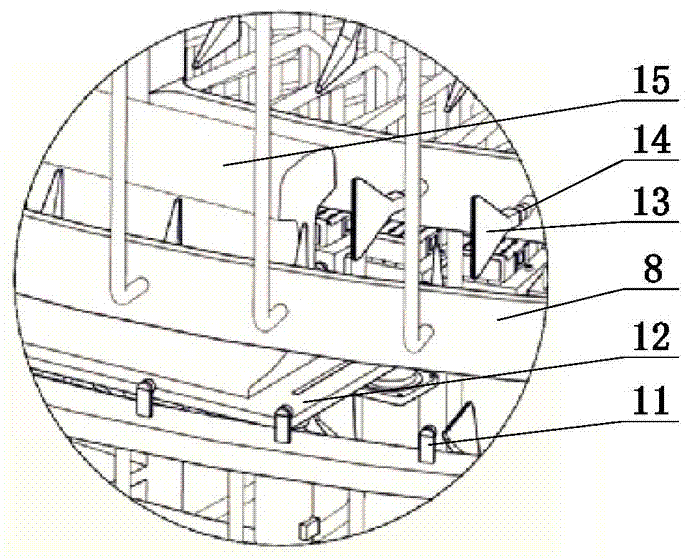

[0018] The present invention includes a blast pressure control system and a quenching system connected to a gas source, and is characterized in that: the quenching system includes a frame 8 with a circular track, and a rail fixing frame 12 with a traveling device is arranged on the circular track, and the frame 8 Corresponding to the top, bottom, left and right of the circular track, nozzles 13 are arranged, and the nozzles 13 are connected with the blast pressure control system; the rail fixing frame 12 is provided with longitudinal displacement sensors 17 and lateral Displacement sensor 18.

[0019] As a preferred solution of the present invention, an infrared sensor 11 is arranged corresponding to the side of the circular track on the frame 8, and the infrared sensor 11 is connected with an electric control system, and the nozzle 13 and the blast pressure control A solenoid valve 22 connected to the electric control system is arranged between the systems; the longitudinal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com