Circular weft knitting machine broken needle detection mechanism

A technology for knitting circular weft machine and broken needle detection, which is applied to knitting, textiles and paper making, etc., can solve the problems of false alarms, the inability of the grating detection device to be completely accurately detected, frequent and other problems, and achieve accurate broken needle detection, simple structure and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

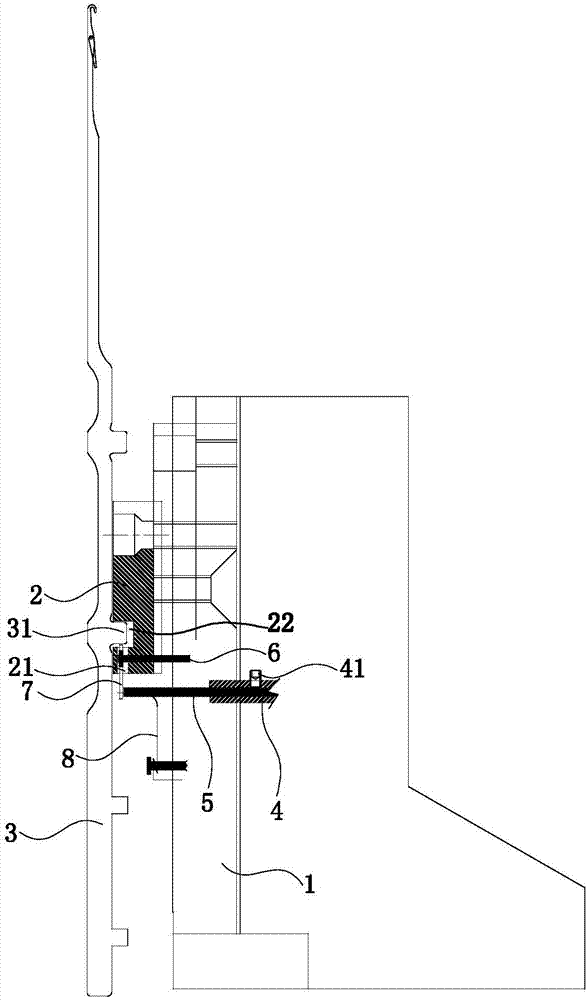

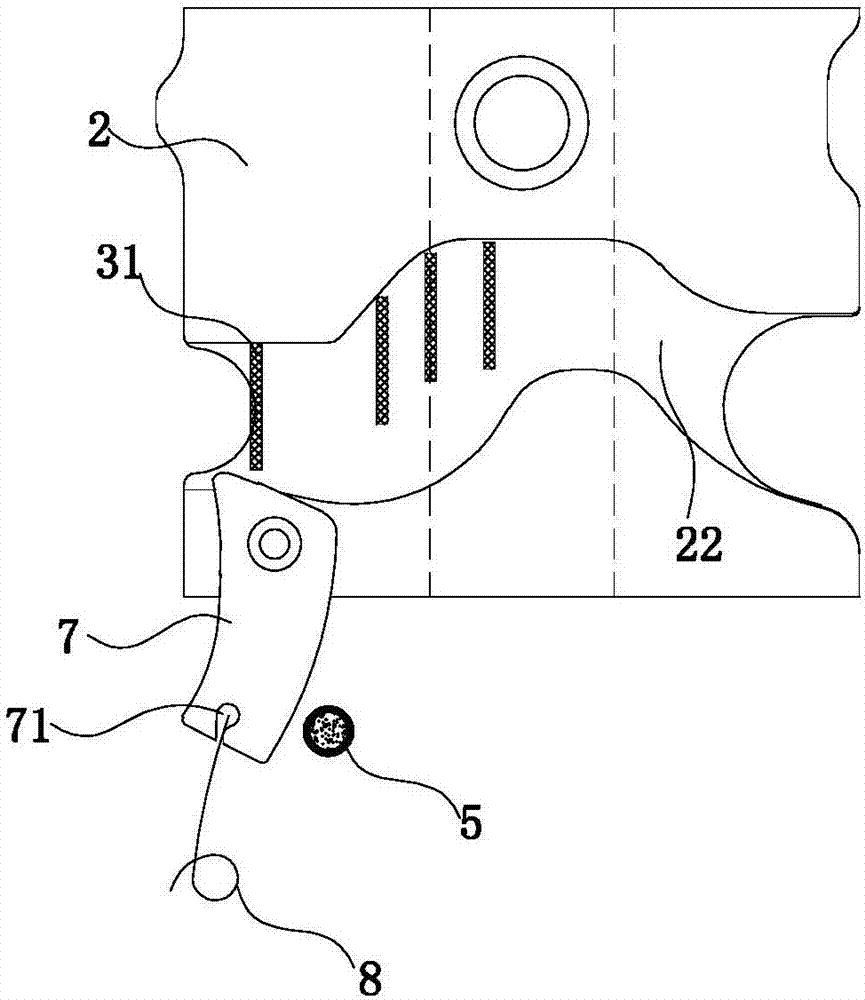

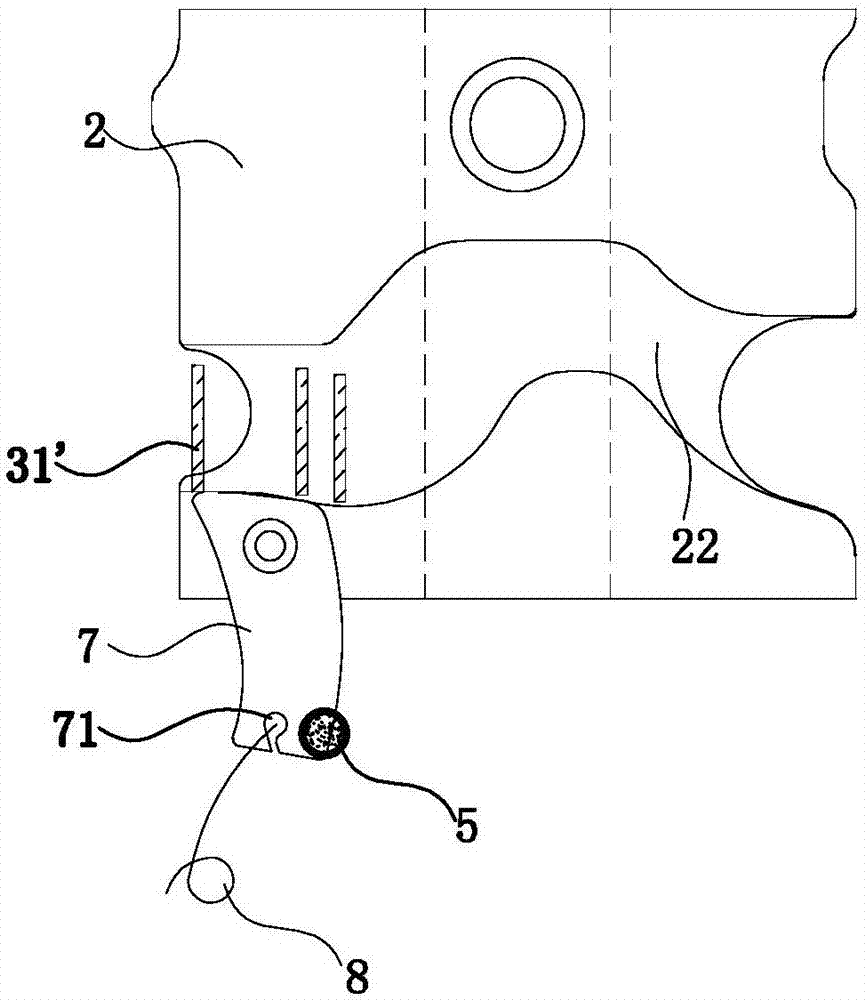

[0015] refer to figure 1 , the present embodiment provides a broken needle detection mechanism for a circular knitting machine, which is arranged on the cam 2 of the saddle 1, including a pin 6 on the cam 2, and a swing piece rotatably arranged on the free end of the pin 6 7. The casing 4 arranged on the saddle 1, the sensor 5 arranged in the casing 4, the return spring 8 arranged on the saddle 1, the casing 4 is provided with a bolt 41 for locking the sensor 5 The bottom of the swinging piece 7 is provided with a notch 71, the free end of the return spring 8 is connected to the notch 71 of the swinging piece 7, the triangle 2 is provided with a through hole 21 communicating with the running track 22, and the swinging piece 7 is located in the triangle 2, and the swinging piece 7 is located below the butt 31 of the knitting needle 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com