Advance pre-grouting construction method for underwater tunnel in case of fault zone

A construction method and pre-grouting technology, applied in tunnels, tunnel linings, earth-moving drilling, etc., can solve the problems of failure to grouting, construction period, cost increase, judging the location and scale of unfavorable geological bodies, etc., so as to reduce the risk of water inrush , The effect of reducing pumping and drainage costs and reducing the risk of water inrush

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

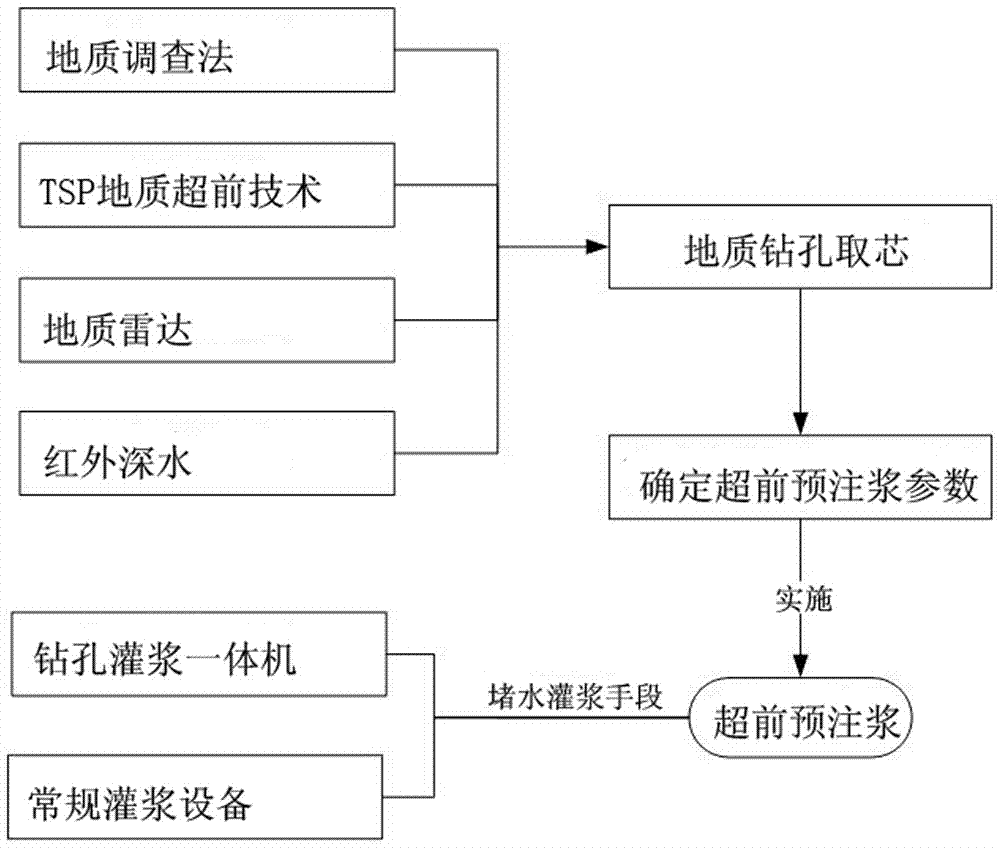

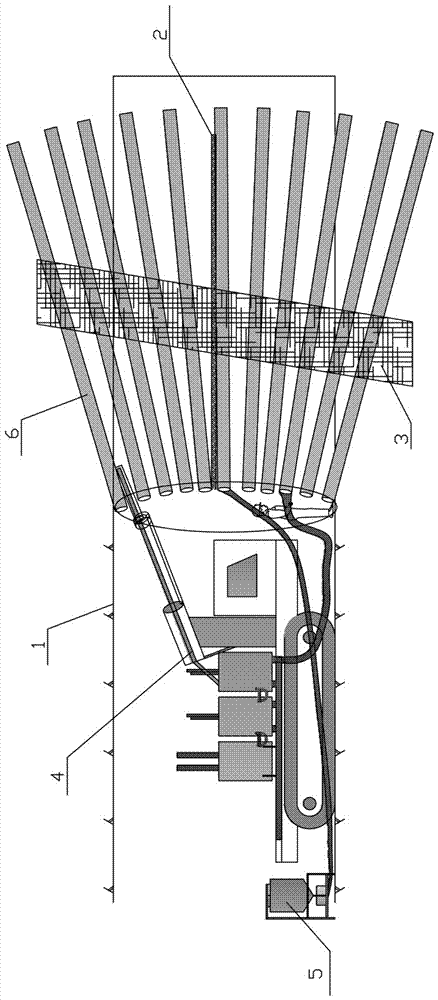

[0020] Such as figure 1 , figure 2 As shown, this embodiment is an advanced pre-grouting construction method for an underwater tunnel encountering a fault zone, which adopts advanced geological forecasting, advanced drilling and coring follow-up, integrated drilling and grouting machine and conventional grouting methods. The specific steps are as follows:

[0021] a. Carry out advanced geological prediction of the tunnel face at the face of underwater tunnel 1;

[0022] a1. Mainly adopt the geological survey method, combined with TSP geological advance technology to find out the macroscopic geological structure within the range of 100-200m in front of the underwater tunnel 1, such as the fault 3;

[0023] a2. According to the means of geological radar and infrared water detection and geophysical prospecting, the degree of fragmentation and water-richness of the surrounding rock in the range of about 25-30m in front of the underwater tunnel 1 is detected, so as to determine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com