A check valve of a liquid oxygen-added conveying system and a liquid-oxygen-added conveying system

A conveying system and non-return valve technology, applied in valve details, valve devices, control valves, etc., can solve problems such as inability to adjust, large take-off height, and inability to fall back and seal in time, so as to improve the non-return effect and ensure accuracy , to ensure the deterministic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The working principle of the present invention will be described in more detail below in conjunction with the accompanying drawings.

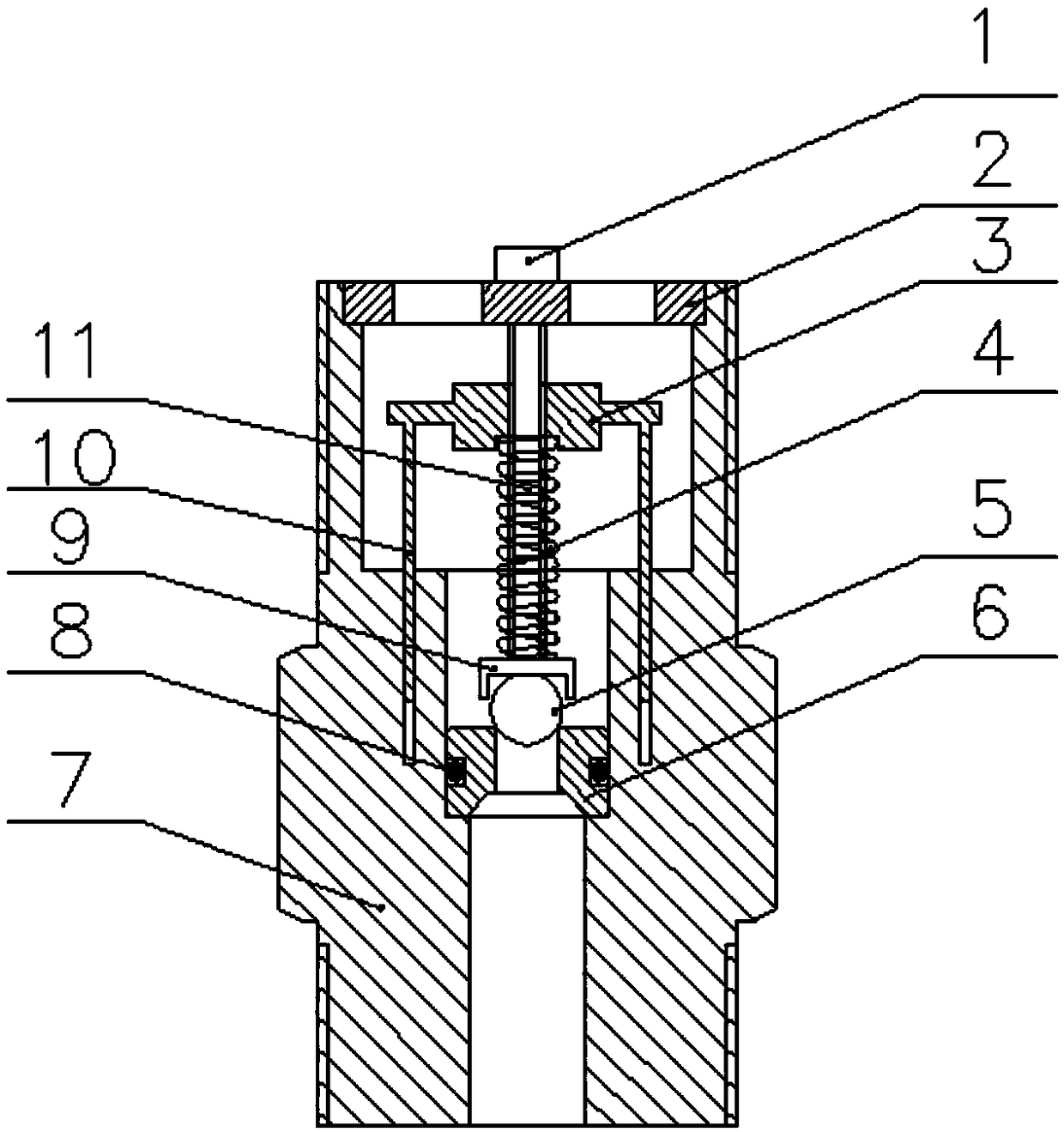

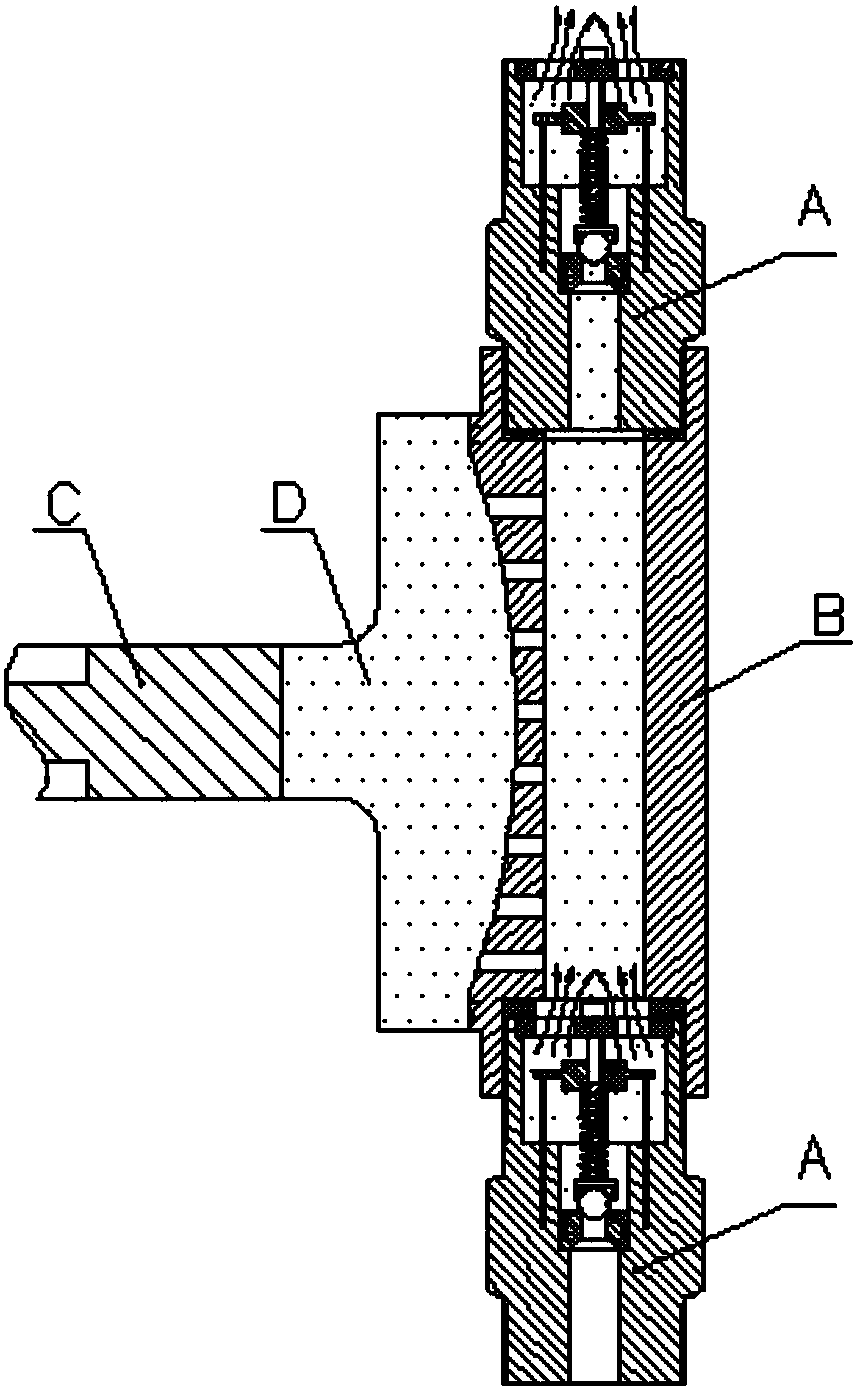

[0018] Such as figure 1 As shown, a check valve of a liquid oxygen delivery system in the present invention includes a check valve body 7, and both ends of the valve body 7 have external threads, which can be connected with external pipelines through threads, and the sealing ring 8 is set on the valve seat 6 In the sealing groove, the axial seal is realized, the check valve ball 5 cooperates with the sharp edge of the inner hole of the valve seat 6 to realize the line seal, the threaded rod 11 acts on the valve ball 5 through the ball cover 9, and the spring 4 is placed on the vernier 3 Between the ball cover 9 and the ball cover 9, the cursor 3 is always in the round hole on the top of the valve body 7 through two guide rods 10, so as to realize the circumferential positioning of the cursor 3, so the cursor 3 can slide on the threaded r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com