Communication protocol configuration engine and real-time monitoring method of air compressor IoT module based on cloud computing

A technology of communication protocol and configuration engine, applied in general control systems, electrical testing/monitoring, testing/monitoring control systems, etc., can solve compatibility problems, large R&D workload, and high production costs, so as to solve compatibility problems , The effect of less R&D workload and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

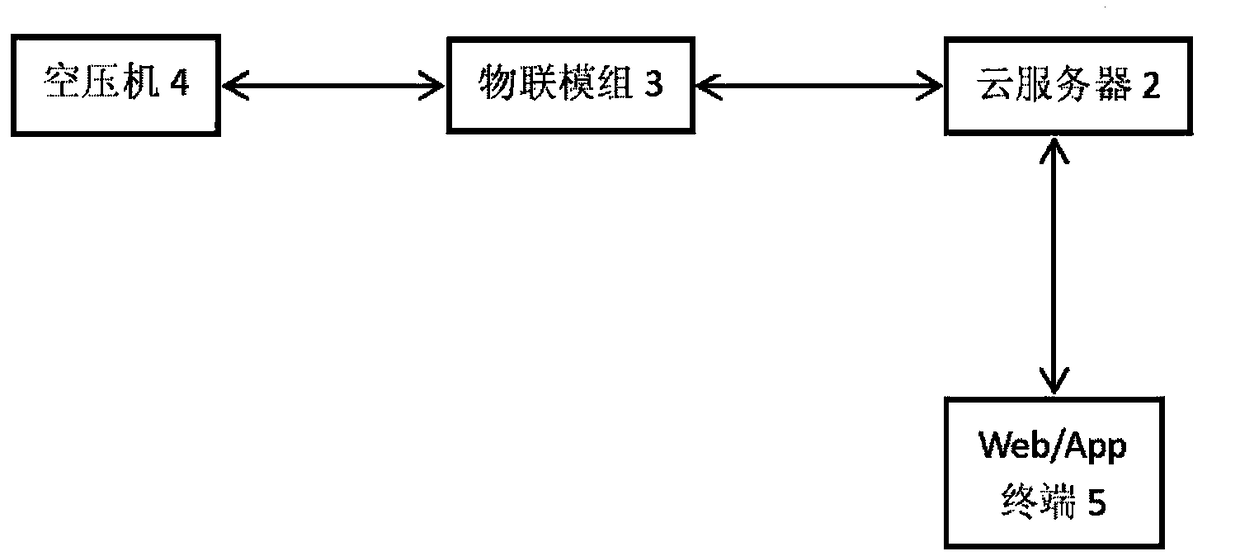

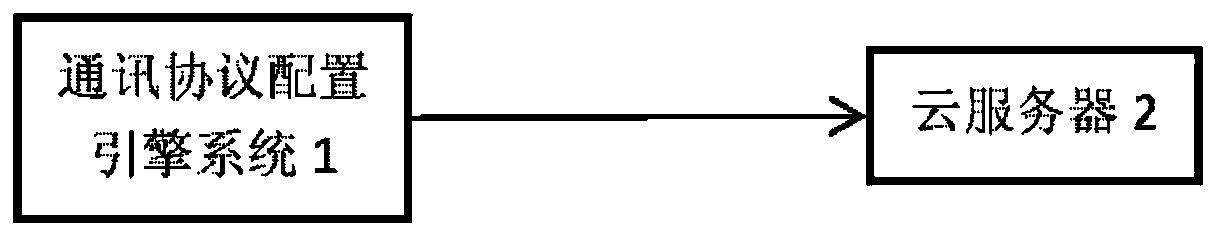

[0029] refer to figure 1 and figure 2 The communication protocol configuration engine of the air compressor IoT module based on cloud computing involved in this embodiment includes a communication protocol configuration engine system 1 and a remote monitoring system. The remote monitoring system includes a cloud server 2, an IoT module 3, an air Press equipment 4 and Web / App terminal 5. The communication protocol configuration engine system 1 is connected to the cloud server 2, the cloud server 2 is connected to the IoT module 3 and the Web / App terminal 5, and the IoT module 3 is connected to the air compressor device 4.

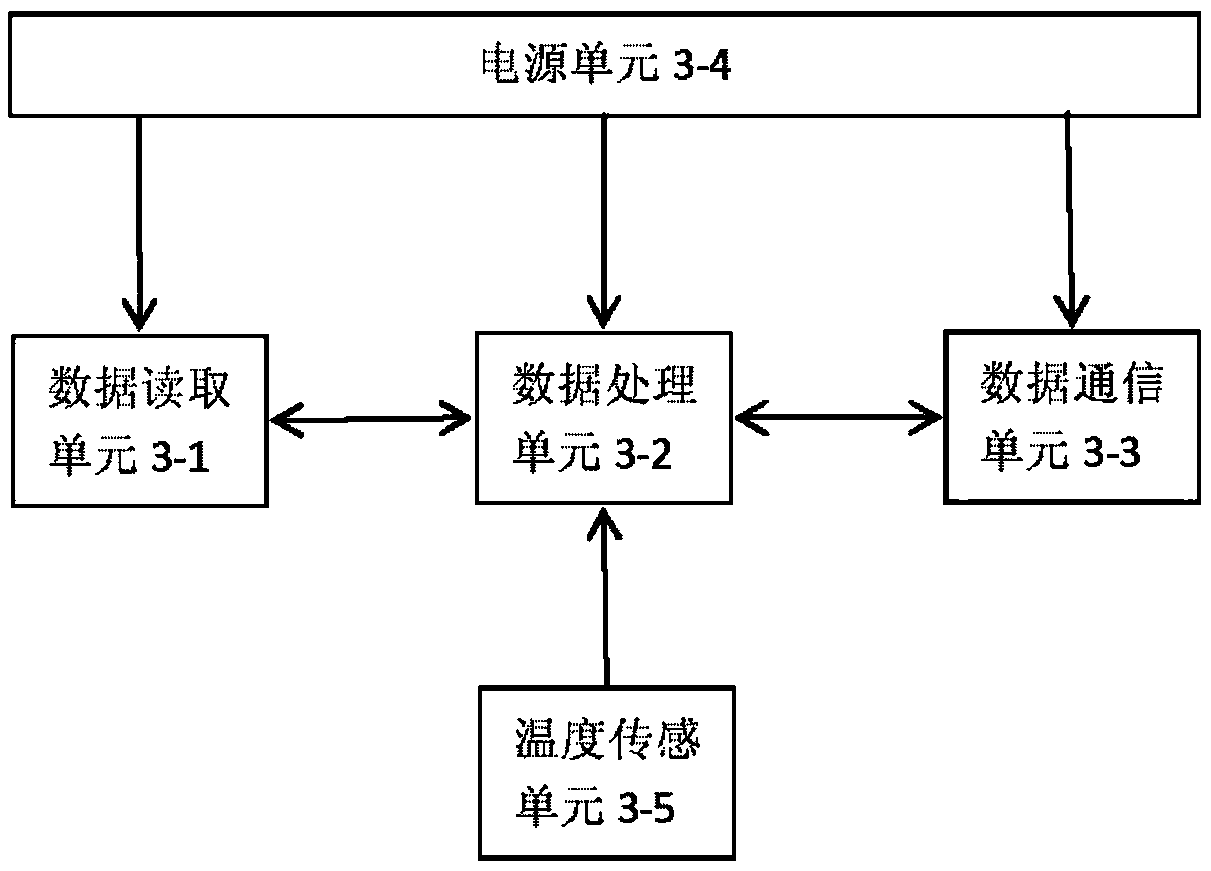

[0030] refer to image 3 , the IoT module 3 includes a data reading unit 3-1, a data processing unit 3-2, a data communication unit 3-3, a power supply unit 3-4 and a temperature sensor unit 3-5, the voltage of the power supply unit The output end is connected to the power input end of the data reading unit 3-1, the data processing unit 3-2, the data com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com