The main circuit and the arc extinguishing chamber are connected in parallel to open and close the ultra-high voltage grounding switch of the induced current

A technology of grounding switch and induction current, which is applied in high-voltage/high-current switch, electric switch, high-voltage air circuit breaker, etc. It can solve the problems that the optimization scheme cannot be adopted, and achieve the advantages of convenient installation, debugging and maintenance, high reliability and convenient modification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

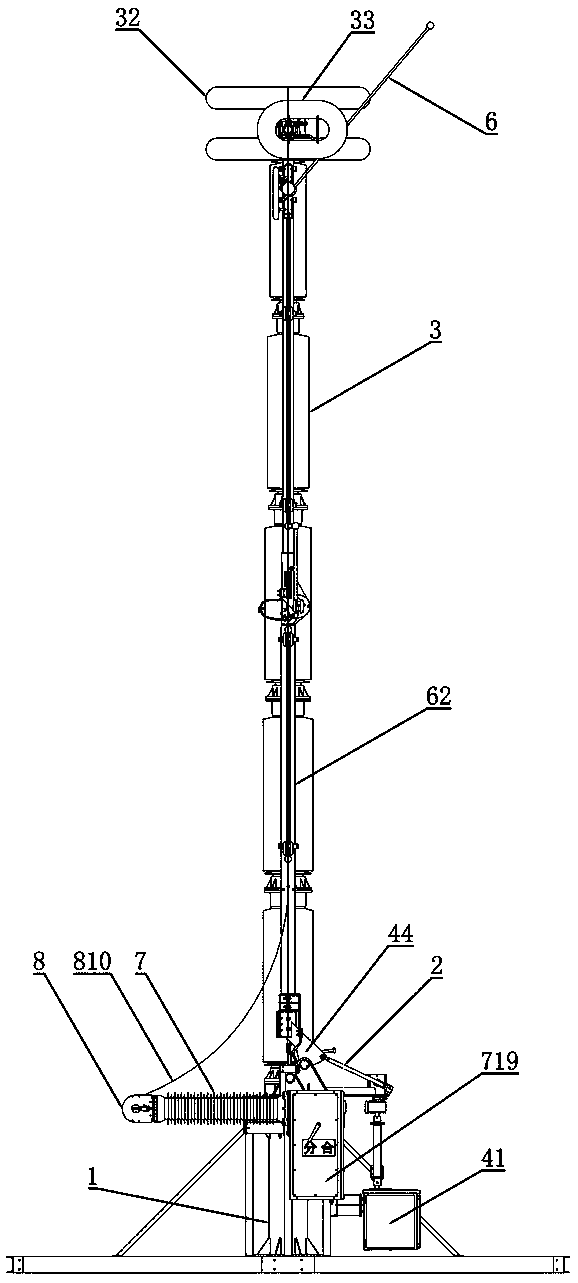

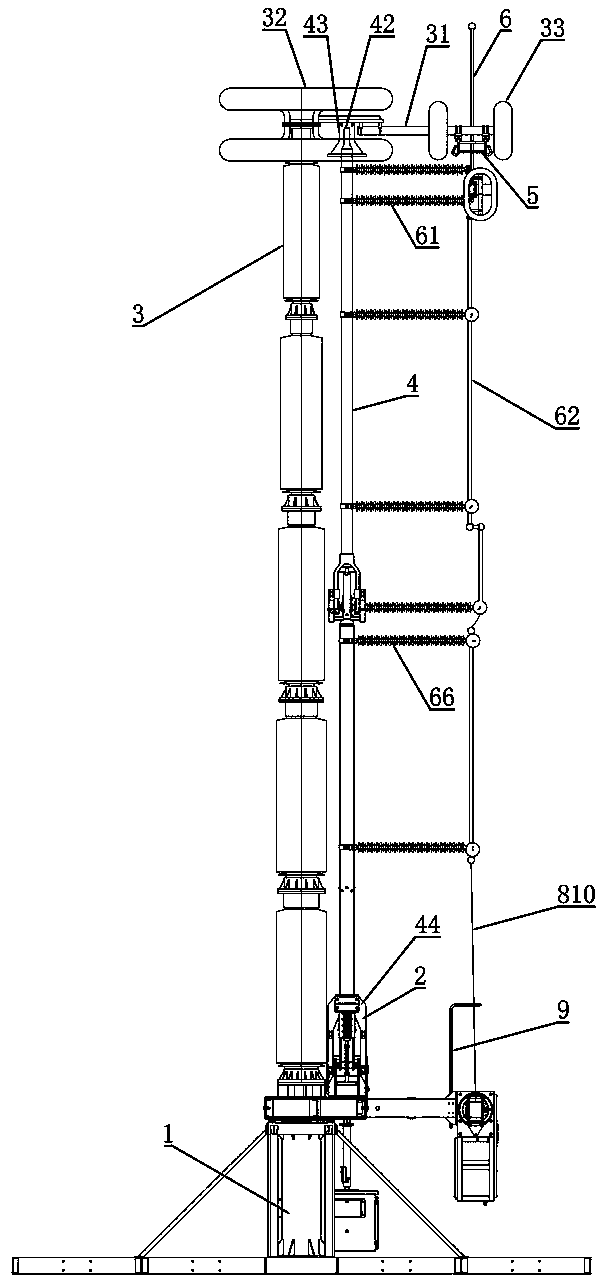

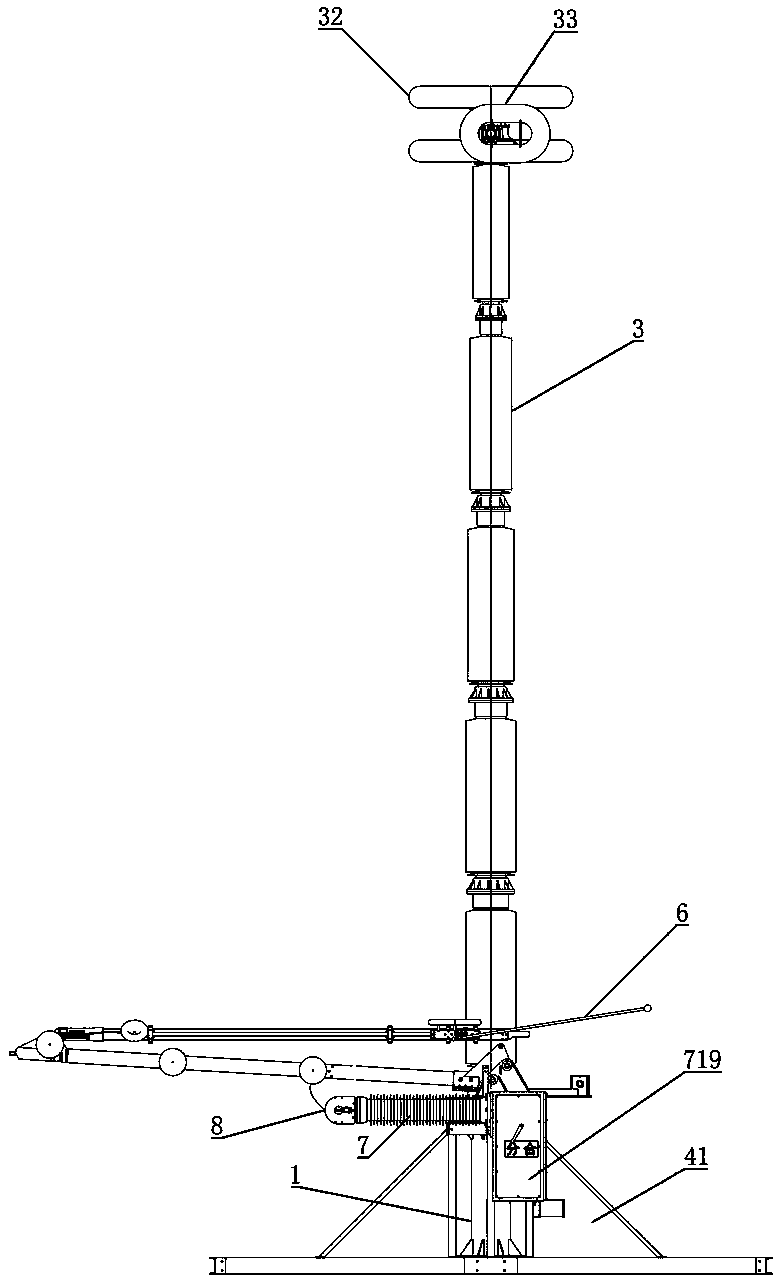

[0035] Such as Figure 1 to Figure 15As shown, the main circuit of this embodiment is connected in parallel with the arc extinguishing chamber to open and close the ultra-high voltage grounding switch of the induced current, including the grounding switch body and the auxiliary circuit. The grounding switch body includes the installation base 2, the porcelain bottle 3, the main switch 4 and the main switch The operating mechanism 41, the installation base 2 is installed on the foundation column 1, the bottom end of the main knife gate 4 is installed on the installation base 2 and connected with the main knife gate operating mechanism 41, the top of the main knife gate 4 is installed with an active contact 42, and the porcelain bottle The bottom end of 3 is installed on the installation base 2, and the main static contact 43 and the main pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com