Charging tray for electric vehicle driving battery

A technology for driving batteries and electric vehicles, applied in electric vehicles, battery circuit devices, secondary battery manufacturing, etc., can solve the problems of battery life extension, battery pressure difference increase, battery cycle times inconsistency, etc., to ensure consistency, Effect of reducing charging risk, improving battery performance and cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

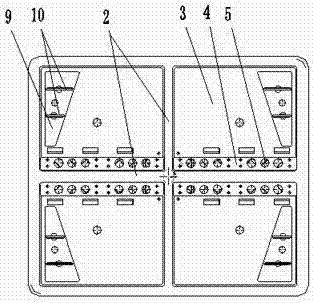

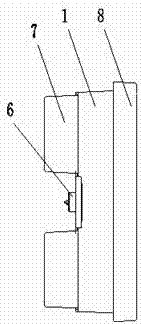

[0016] see figure 1 and figure 2 , as can be seen from the figure, the charging tray for the electric vehicle drive battery of the present invention includes a box body 1 of rectangular structure, the upper surface of the box body 1 is open, and the inside of the box body 1 is separated by two partitions 2 intersecting each other. There are four identical battery placement areas 3, and the size of each battery placement area 3 corresponds to the volume of two batteries so that two batteries can be placed therein. In the battery storage area 3 on both sides of one of the separators 2, a step 4 lower than the separator is provided next to the separator. The length direction of the steps is consistent with the length direction of the separator, and the four battery storage areas correspond to four steps. Two pairs of battery charging interfaces 5 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com