Hard pressurizing oxygen chamber

An oxygen chamber and hardware-based technology, applied in medical science, hospital equipment, treatment rooms, etc., can solve the problems that internal personnel cannot directly control the operation panel, cannot operate the equipment by themselves, waste time and energy, and achieve simple structure and energy saving Space, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

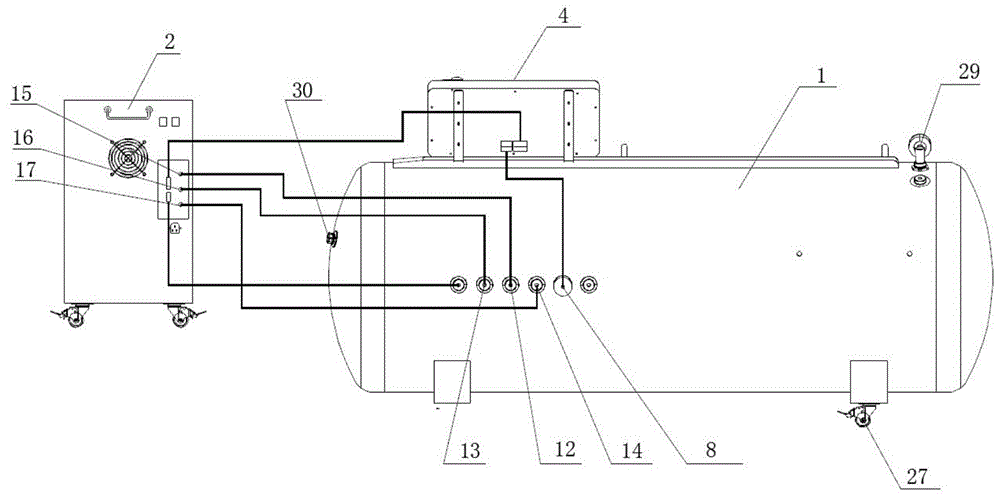

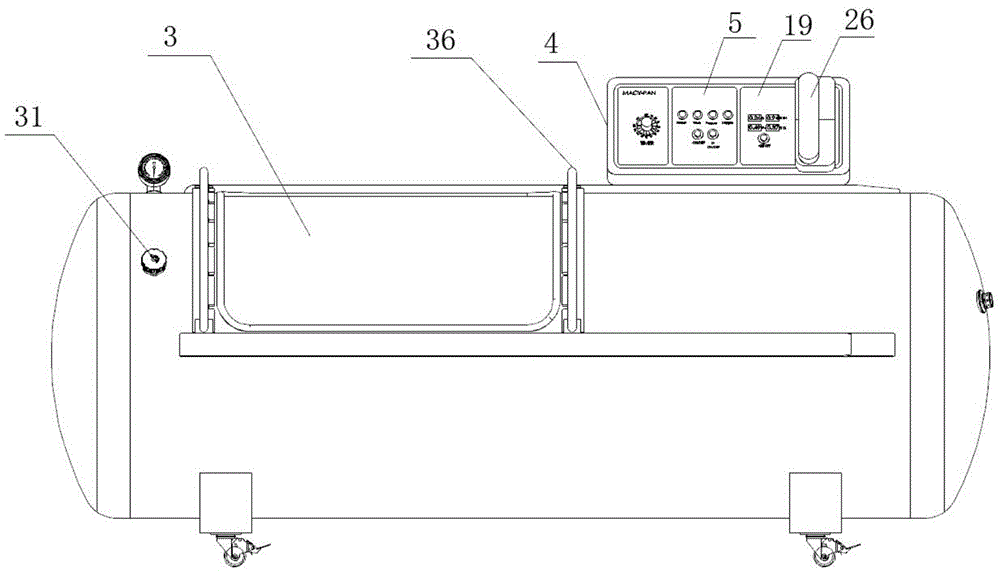

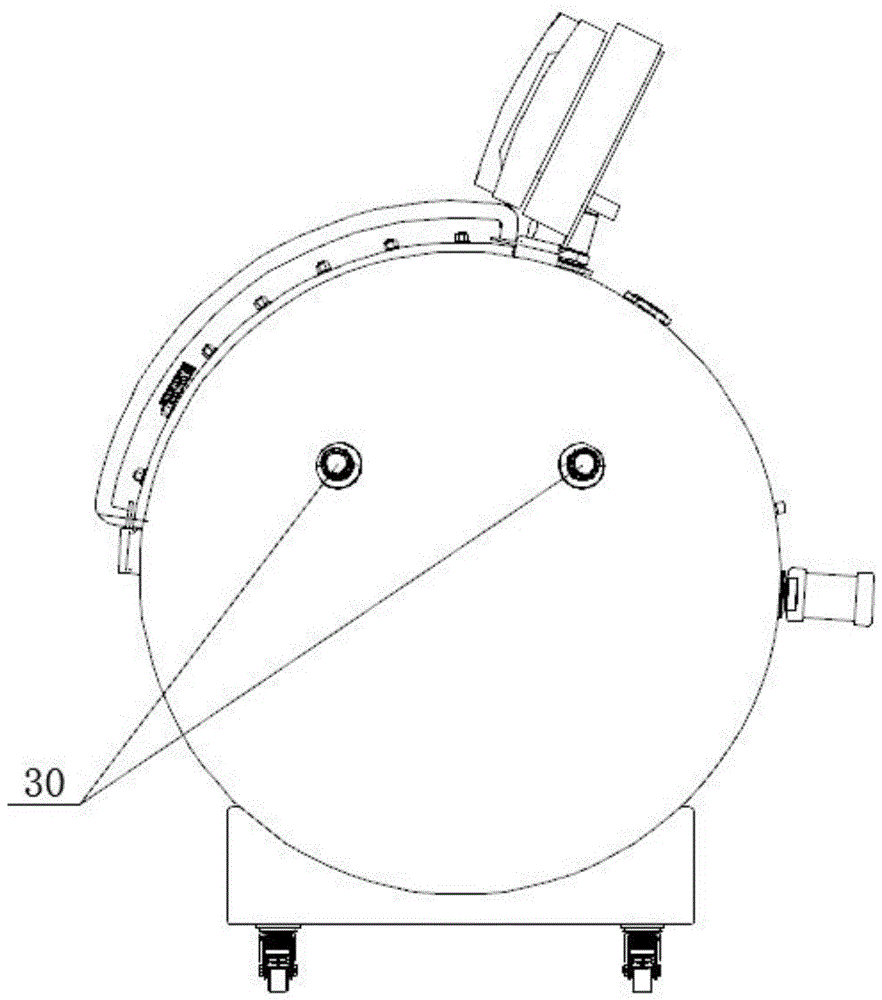

[0032] Such as Figure 1~Figure 3 As shown, the hard body type pressurized oxygen chamber of the present invention includes a main cabin body 1 and a power cabinet 2, the main cabin body 1 is a hollow shell structure, and a push-pull type airtight door 3 is provided on its side wall, and the sealing The door 3 moves up and down through the cylinder 33 and is sealed with the main cabin body 1 by the cylinder 33. In the present embodiment, the airtight door 3 is lifted up after the air intake of the cylinder, and is closely connected with the main cabin body 1 to realize sealing. When the cylinder 33 After depressurization, the airtight door 3 falls and separates from the main cabin body 1, and the airtight door can be pushed and pulled away manually.

[0033] The main cabin body 1 is provided with a controller 4, the controller 4 is provided with an operation panel 5 outside, and a control circuit board 6 is arranged inside, the inside of the main cabin body 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com