A 3D printing layer-by-layer detection reverse part model and device and method for locating defects

A technology of 3D printing and parts, which is applied in the field of 3D printing layer-by-layer detection, reverse part model and defect positioning device, so as to avoid the effect of destructive test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

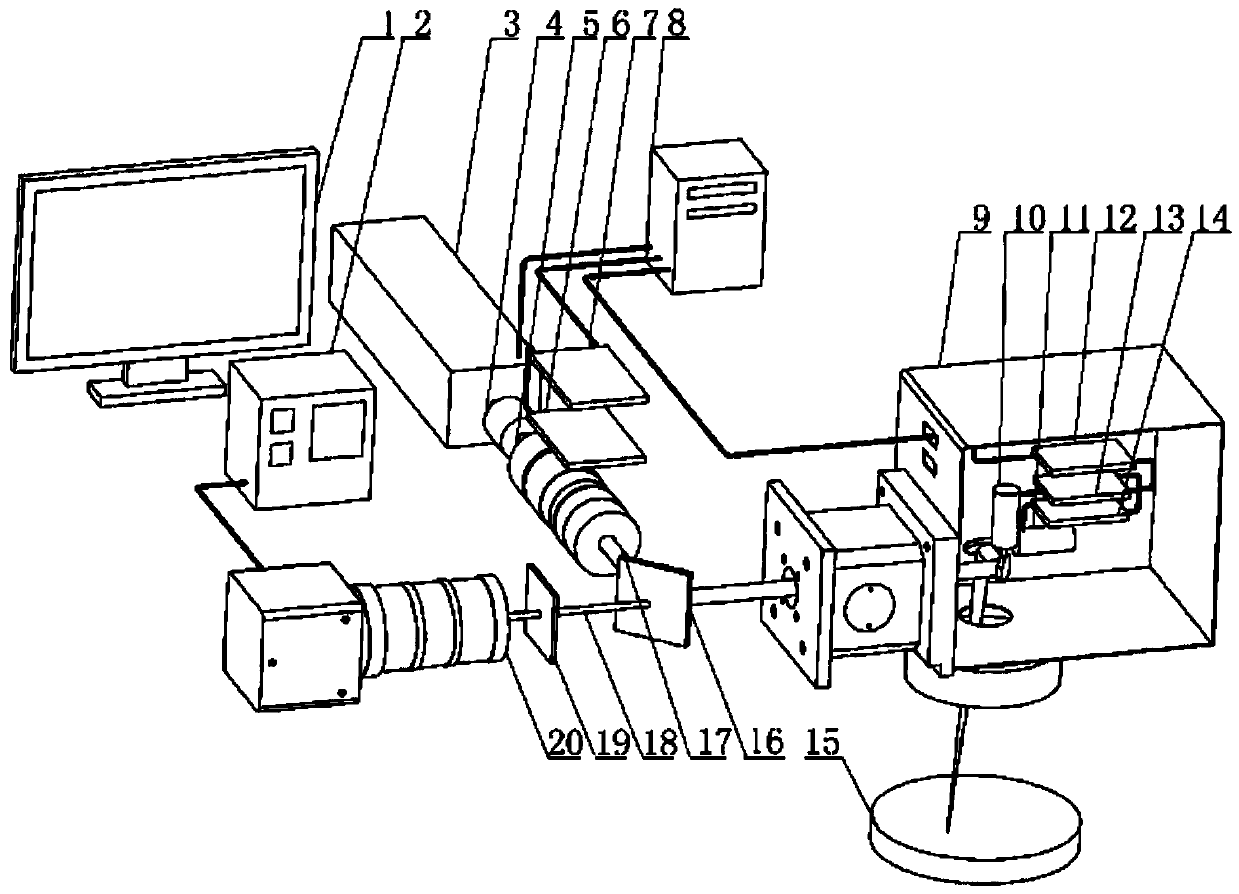

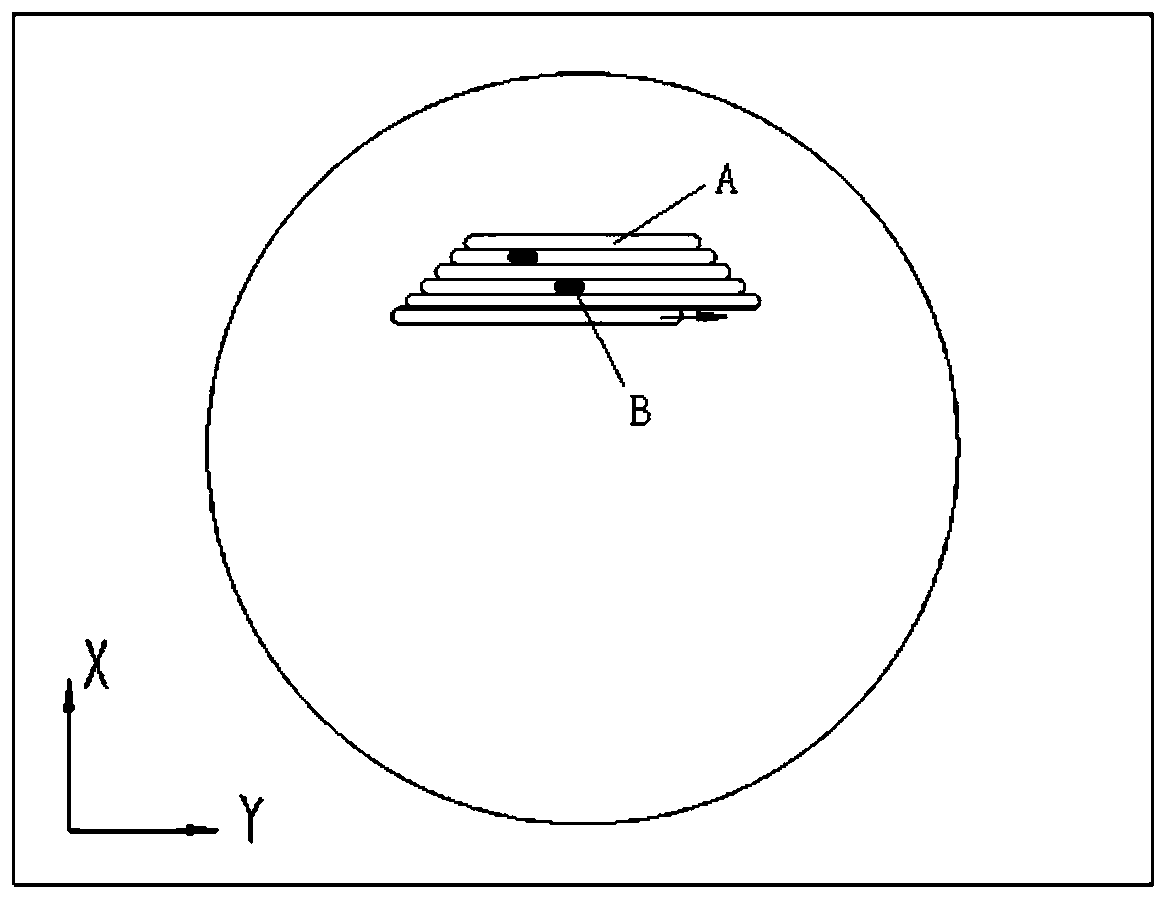

[0032] as the picture shows. The invention discloses a 3D printing layer-by-layer detection and reverse parts model and a device for locating defects, including a laser head 3, a scanning galvanometer 9, a computer 1, a half-transparent mirror 16, a high-speed camera 20, and a controller 2; The high-speed camera 20 is telecommunications connected with the computer 1 through the controller 2;

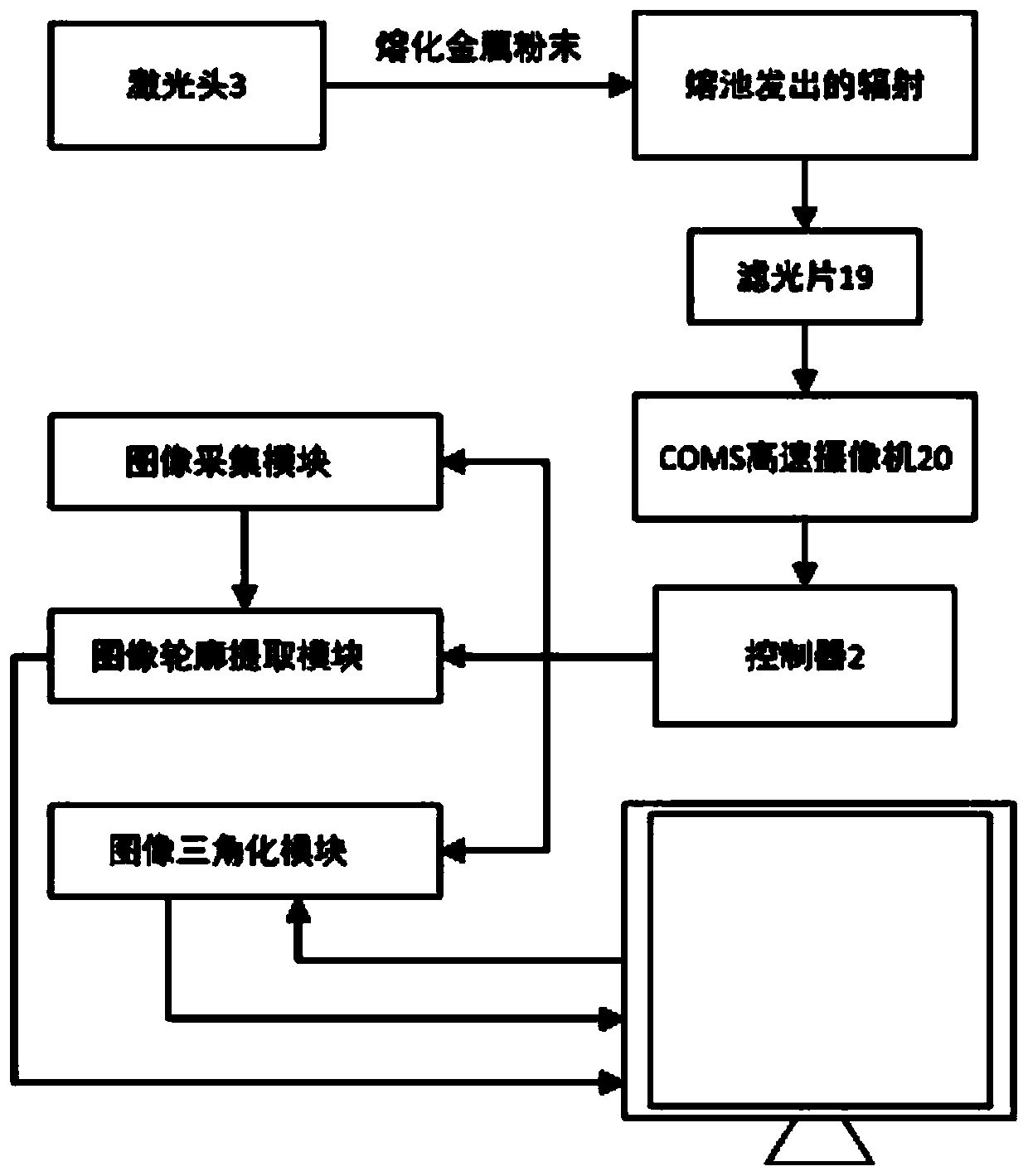

[0033] The laser light path 17 of the laser head 3 is reflected into the scanning vibrating mirror 9 through the semi-transparent mirror 16, and the laser beam is controlled by the scanning vibrating mirror 9 to selectively melt the metal powder laid on the work platform 15; The mirror 9 collects the molten pool radiation, and transmits it to the high-speed camera 20 through the half-transparent mirror 16, and the high-speed camera 20 processes the molten pool radiation data, and converts the image information into the controller 2, and the controller 2 uses It is used to process the im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com