Luminous tube detection method and device thereof

A detection method and detection device technology, applied in measuring devices, optical instrument testing, measuring fluid pressure, etc., can solve problems such as low efficiency and difficulty in realizing full inspection, so as to improve efficiency, reduce product loss, and avoid destructive tests Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

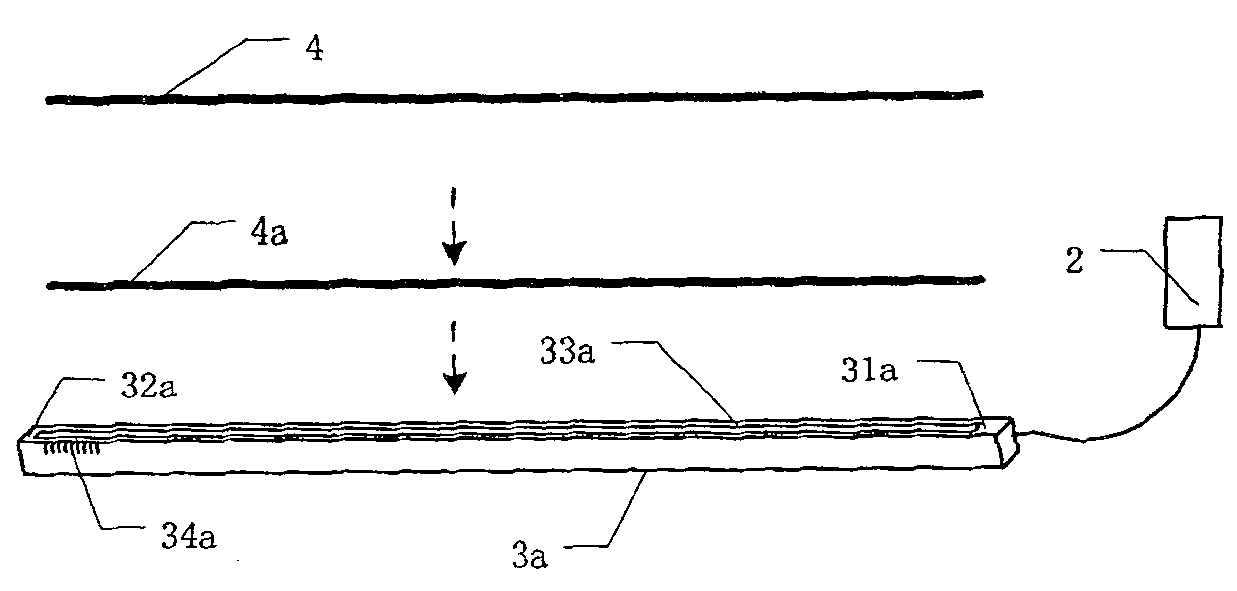

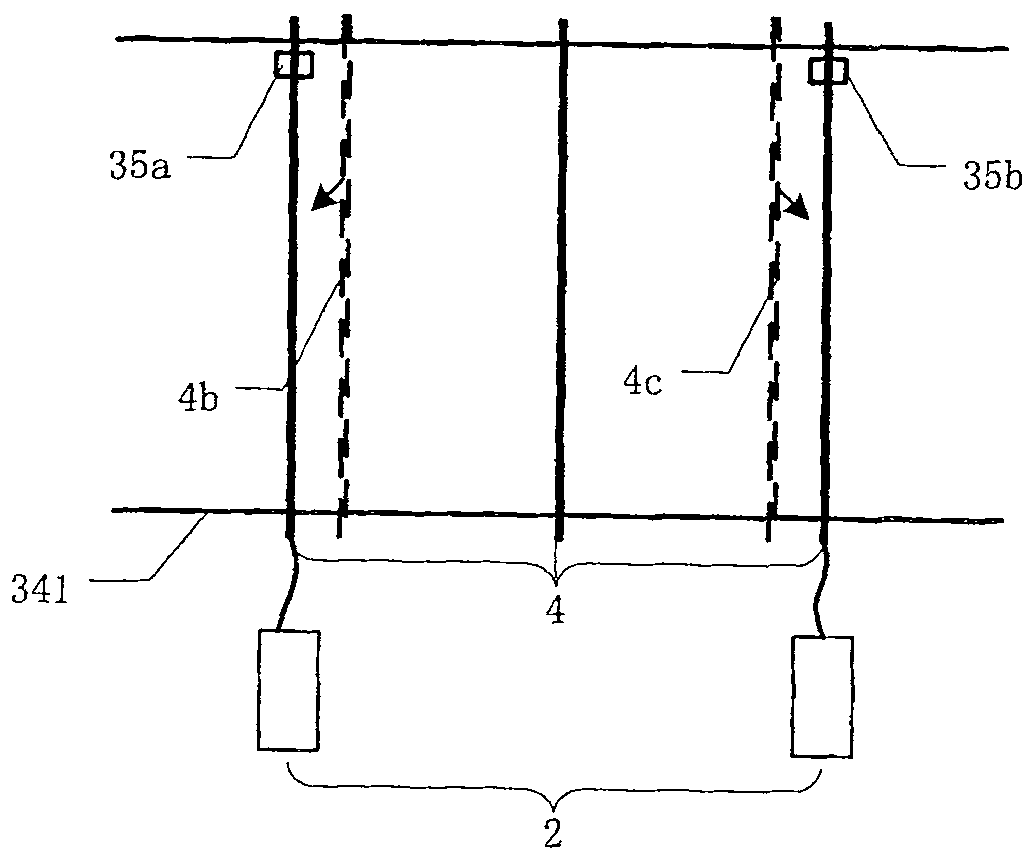

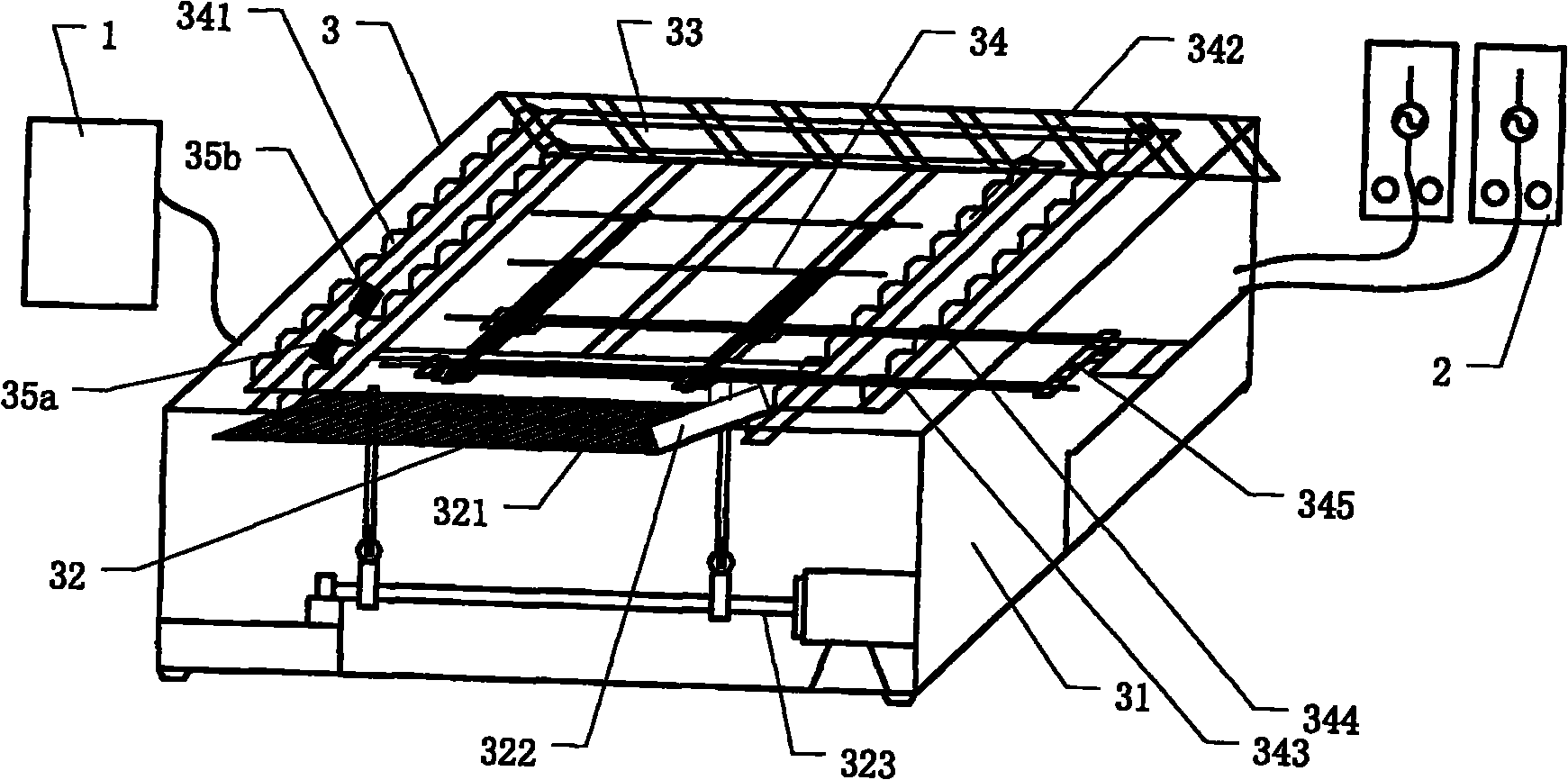

[0059] Such as image 3 Shown is the structural representation of the lamp tube detection device of the present invention, by image 3 It can be seen that the lamp detection device also includes a control unit 1, a power controller 2 and a detection platform 3, and its characteristic design is mainly reflected in that the detection platform 3 has a lamp accommodation groove 33a, a base 31 and a The transfer mechanism 34, wherein:

[0060] One end of the lamp accommodating groove 33a is provided with a high-voltage electrode 31a connected to the power controller 2, and the other end is provided with a low-voltage electrode 32a forming a loop.

[0061] A loading area 32 and an unloading area 33 are fixed on both sides of the upper part of the base 31 , and a conveying mechanism 34 is provided between the loading area 32 and the unloading area 33 . The feeding area 32 includes a feeding guide surface 321, a bakelite block 322 and a feeding cam mechanism 323, the bakelite block ...

Embodiment 2

[0068] Such as Figure 4 As shown, it is a schematic diagram of a further optimized structure of the lamp tube detection device of the present invention. Compared image 3 It can be seen that, in order to minimize the influence of external light on the two sensors, based on the derivation of the first embodiment, a light shield 36 is provided on the detection platform 3 . The shade 36 is connected to one side of the base 31 through a hinge 361 . When the detection device is working, the shading cover 36 can be covered, so that the influence of external light on the two sensors on the detection platform 3 can be effectively shielded, and the detection accuracy can be improved. It should be noted that: the shading cover 36 is openable, connected to any side of the square base 31, and the shape of the shading cover 36 can be image 3 The trapezoidal shape shown can also be arc-shaped or other geometric shapes. In addition, the connection between the shading cover 36 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com