Nozzle quick changing system for 3D printing machine and printing machine

A 3D printer and printing nozzle technology, applied in coating devices, processing and manufacturing, liquid material additive processing, etc., can solve problems such as poor expansion ability, small range of printable materials, and inability to meet the needs of multi-material printing, etc. To achieve the effect of compact device, improve printing efficiency, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the drawings and implementation process.

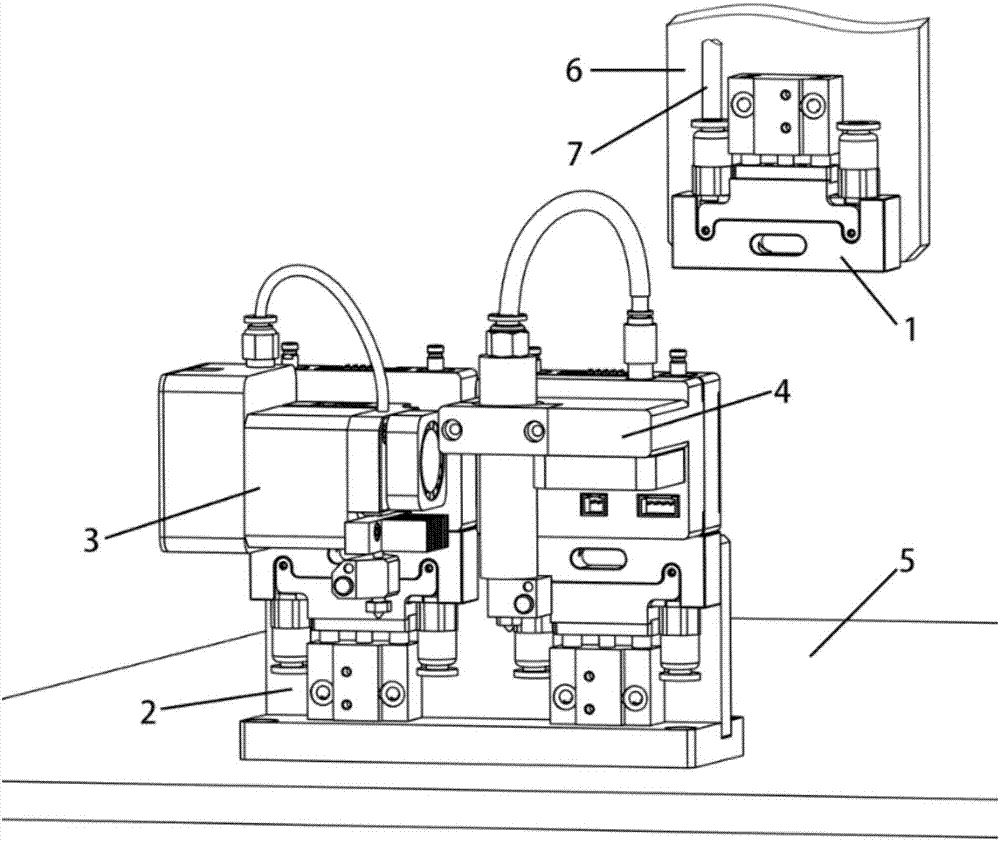

[0046] Such as figure 1 As shown, a nozzle quick-change system that can be used for 3D printers includes a motion mechanism grabbing module 1, a nozzle library 2, and nozzle modules with different functions. figure 1 The nozzle modules shown in are the motor extrusion nozzle module 3 and the pneumatic extrusion nozzle module 4.

[0047] The nozzle library 2 is fixed on the printing platform 5 .

[0048] The kinematic mechanism grabbing module 1 is fixed on the kinematic arm 6 of the 3D printer. The moving arm 6 is fixed on the moving mechanism of the 3D printer (not shown in the figure).

[0049] The grasping module 1 of the moving mechanism is connected to a compressed air source through an air source air pipe 7 .

[0050] In the present invention, the grasping module needs to have the output interface of the electrical signal and control signal requ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap