Unmanned aerial vehicle hangar

A technology for hangars and drones, applied in motor vehicles, aircraft parts, buildings where cars are parked, etc., can solve the problems of low charging efficiency and high cost of charging equipment, to ensure safety, improve land use efficiency, ensure Effects of stability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

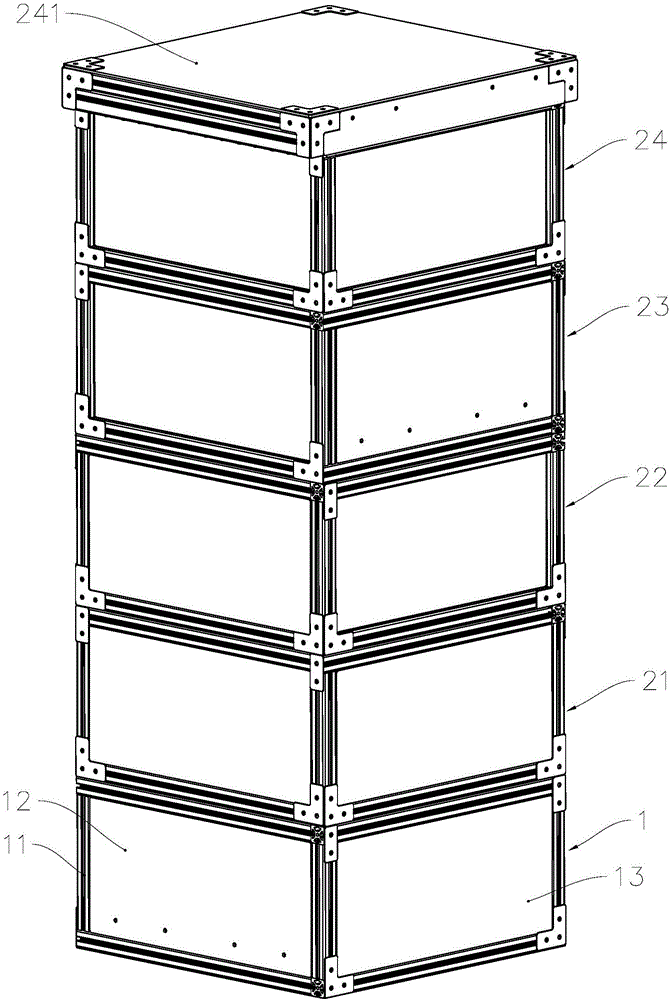

[0031] see figure 1 , from bottom to top, the UAV hangar includes a controller, a library unit 1, a library unit 21, a library unit 22, a library unit 23 and a top library unit 24, and the adjacent two layers of library units are detachably fixed by fixing pieces In actual use, different layers of library units can be configured according to the number of drones that need to be docked.

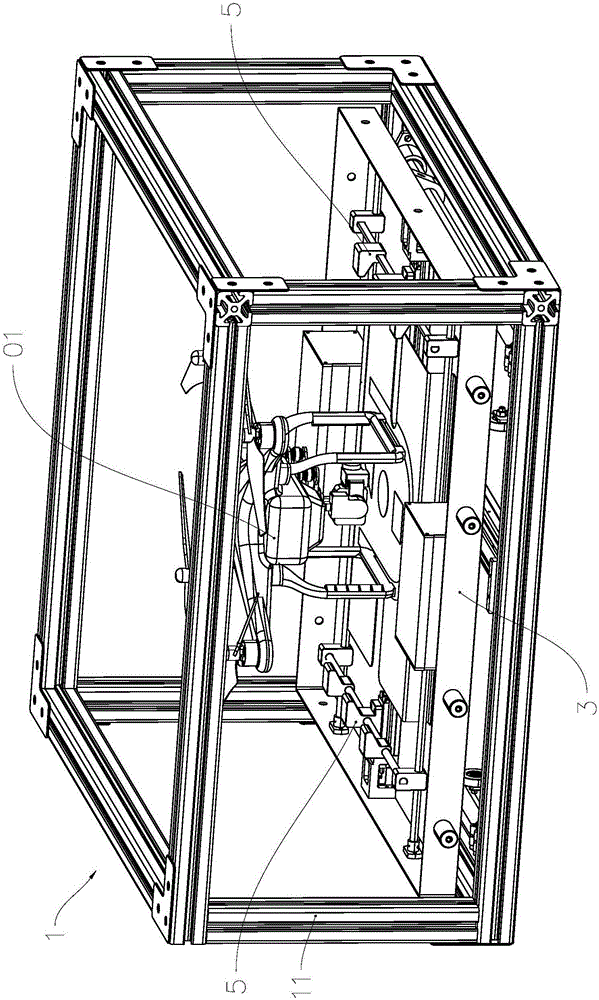

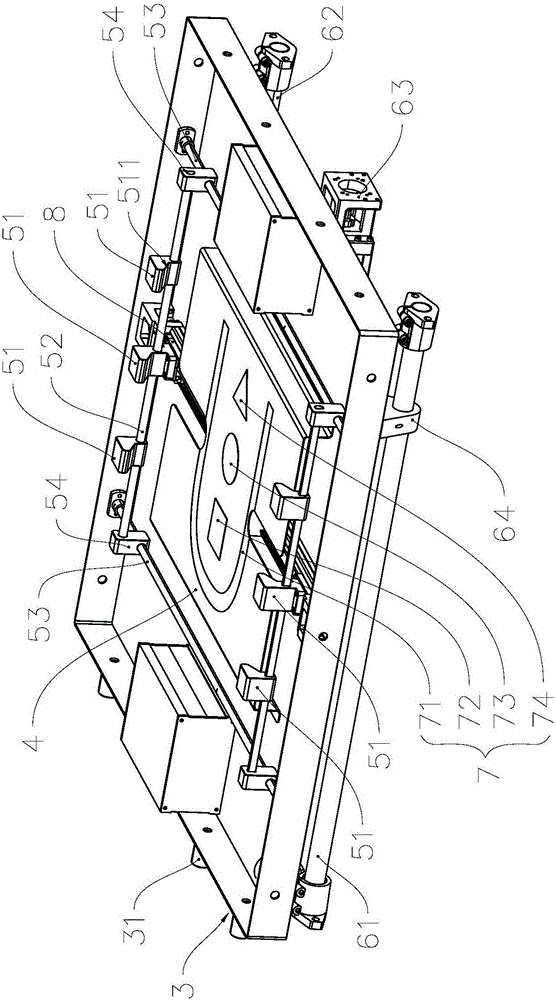

[0032] see Figure 1 to Figure 4, taking the library unit 1 at the bottom as an example to illustrate the structure of the library unit, which includes a support frame 11, a protective case and a push-pull drawer structure installed in the protective case. The push-pull drawer structure includes a push-pull plate 3, an apron 4, A pair of clamping components 5 and a push-pull actuator 63 that drives the push-pull plate 3 to slide along the guide rods 61 and 62 .

[0033] Both the apron 4 and the pressing assembly 5 are installed on the push-pull plate 3 to be pushed out or pulled into the pro...

Embodiment 2

[0070] As a description of Embodiment 2 of the present invention, only the differences from Embodiment 1 above will be described below.

[0071] see Figure 5 to Figure 8 , the apron 4 is a hollow plate structure, which is supported by a plurality of support plates between it and the push-pull plate 32, forming an overhead layer structure with ventilation on both sides; the two side plates 33 of the drawer structure are all provided with through holes and are used in night environments. The LED light strip 35 for the lower lighting, the front panel 34 and the push-pull plate 32 are hinged through a hinge, and the actuator 36 is used to push the front panel 34 to rotate around the hinge axis to control the front panel 34 to switch between the tiled position and the erect position. By setting through holes on the apron 4 and the side plate 33, and making the front panel 34 in a flat state during the take-off and landing of the drone, the rebound to the downwash airflow of the ro...

Embodiment 3

[0086] As an explanation of Embodiment 3 of the present invention, only the differences from Embodiment 1 above will be described below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com