Warp knitting machine

A warp knitting machine and drive mechanism technology, applied in the field of warp knitting machines, can solve problems such as large structural space, and achieve the effects of saving structural elements, small mass, and structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

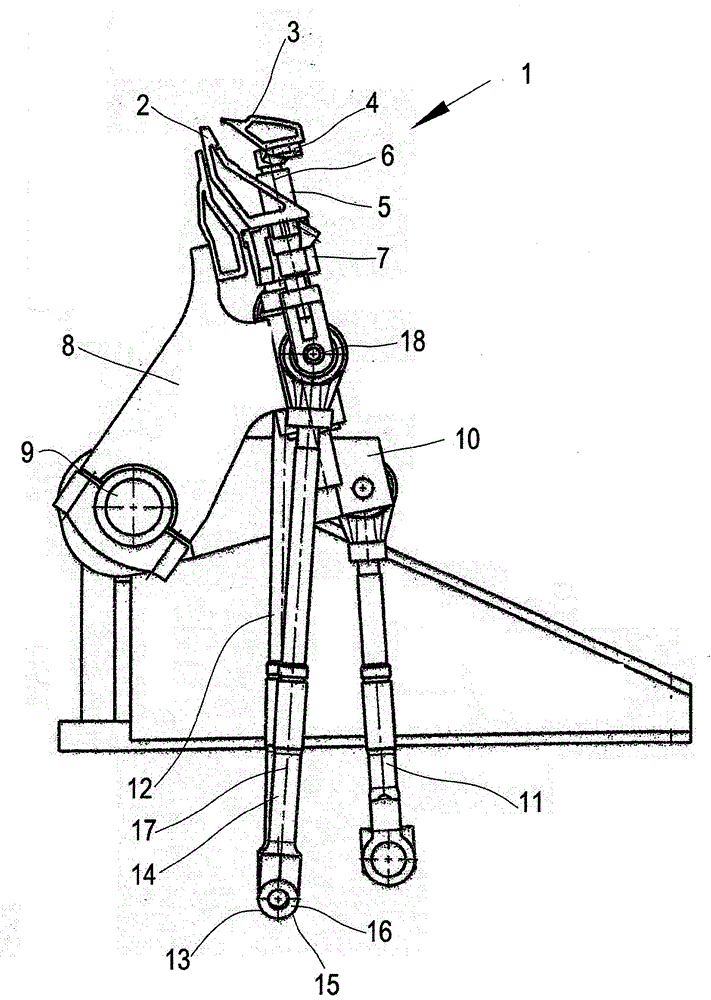

[0020] In the figure a part of a warp knitting machine 1 is shown with a needle bar 2 carrying a large number of knitting needles which are arranged one behind the other perpendicular to the plane of the drawing. The knitting needles are not shown in the drawings. Furthermore, the warp knitting machine 1 has a sliding bar 3 which carries a slide for each knitting needle. Sliders are also not shown.

[0021] The sliding bar 3 is fixed on a sliding bar carrier 4 which is guided in a linear guide 5 . The linear guide 5 has a plurality of linear guides which are arranged one behind the other perpendicular to the plane of the drawing. The linear guide 5 has a guide direction 6 .

[0022] The linear guide 5 is arranged in a pin bar carrier 7 which carries the pin bar 2 . The needle bar carrier 7 is in turn mounted movably on a carrier bar 8 . The carrier rod 8 is fixed on the shaft 9 in a rotationally fixed manner. The shaft 9 is driven in an oscillating movement by a tripper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com