Flexible connected joint structure of externally-bonded masonry wall and steel column

A technology of flexible connection and node structure, which is applied in the direction of building structure and construction, can solve the problems of hindering the horizontal displacement of structural factory building columns and free deformation of enclosure walls, so as to achieve clear force transmission, simple construction, and eliminate incompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in combination with specific embodiments.

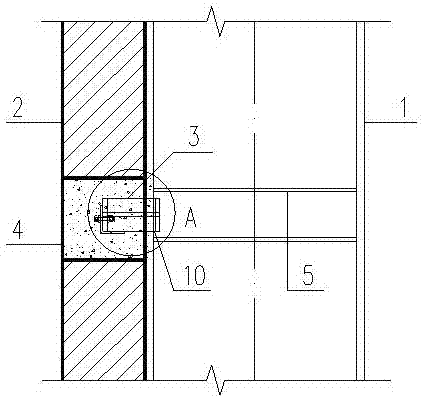

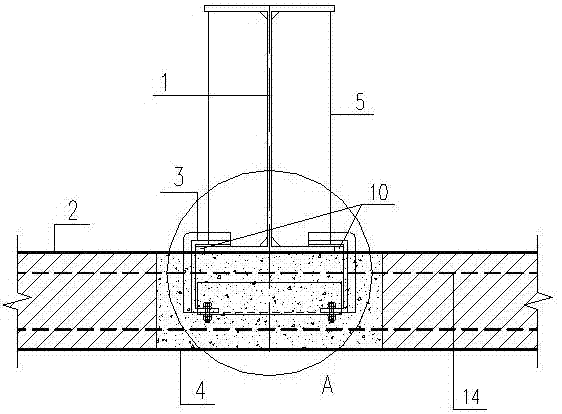

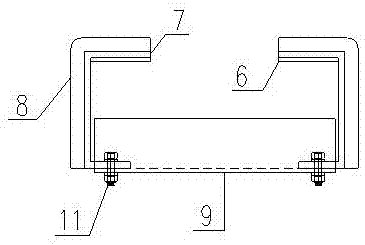

[0030] The invention relates to a flexible connection node structure between an externally attached masonry wall and a steel column. By setting a special connecting device between the externally attached masonry wall and the steel column, the connection between the externally attached masonry wall and the steel column is solved, which greatly improves the The mechanical performance of the main structure is improved. On the premise of ensuring the effective connection between the wall and the steel column, the longitudinal free deformation of the wall and the steel column can be satisfied, thereby effectively protecting the safety of the main structure under earthquake action. It specifically includes a steel column 1 and an externally attached masonry wall 2; the externally attached masonry wall 2 has intermittent slots and is provided with a sliding connection device 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com