Variable-gravity orientation typical friction pair sliding abrasion tester and test method

A technology of friction pairs and testing machines, which is applied in the direction of applying repetitive force/pulsation force to test material strength, test wear resistance, and measuring devices, etc. It can solve the problem of poor authenticity, unsatisfactory effectiveness, and inability to solve three-dimensional moving ground with complex trajectories. Simulate problems and other problems to achieve the effect of improving measurement accuracy and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

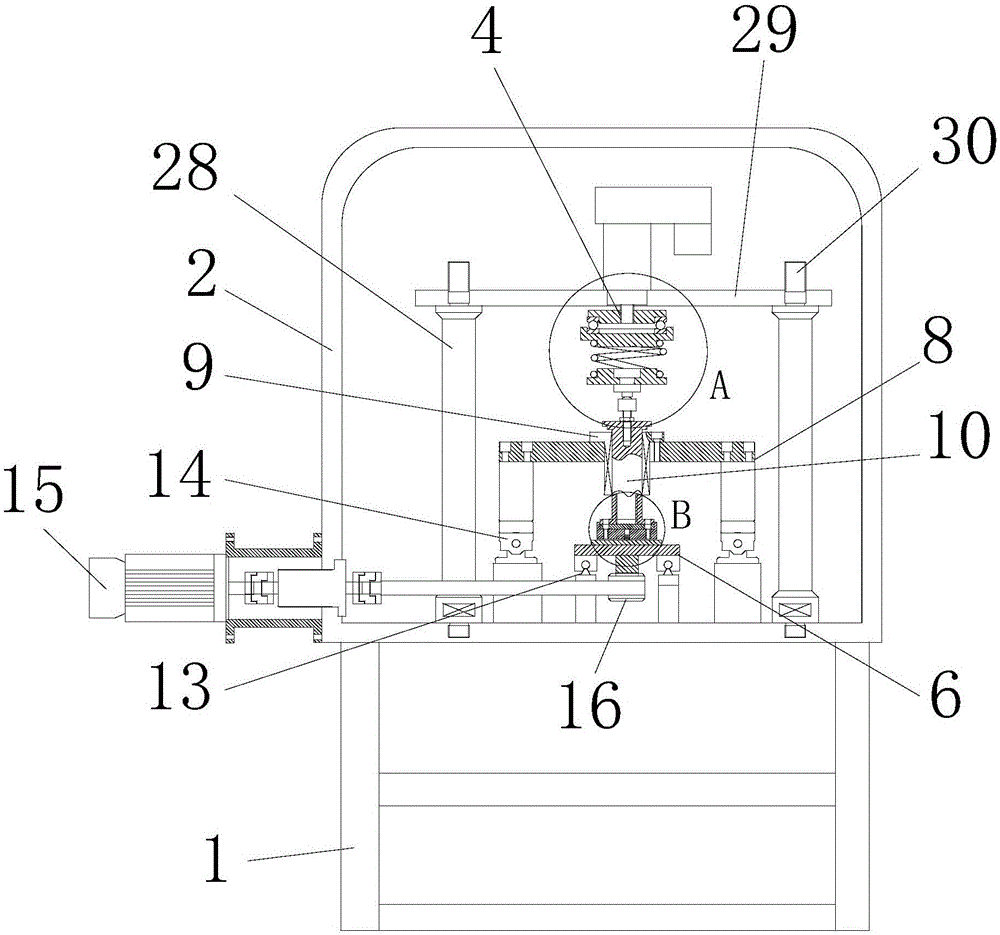

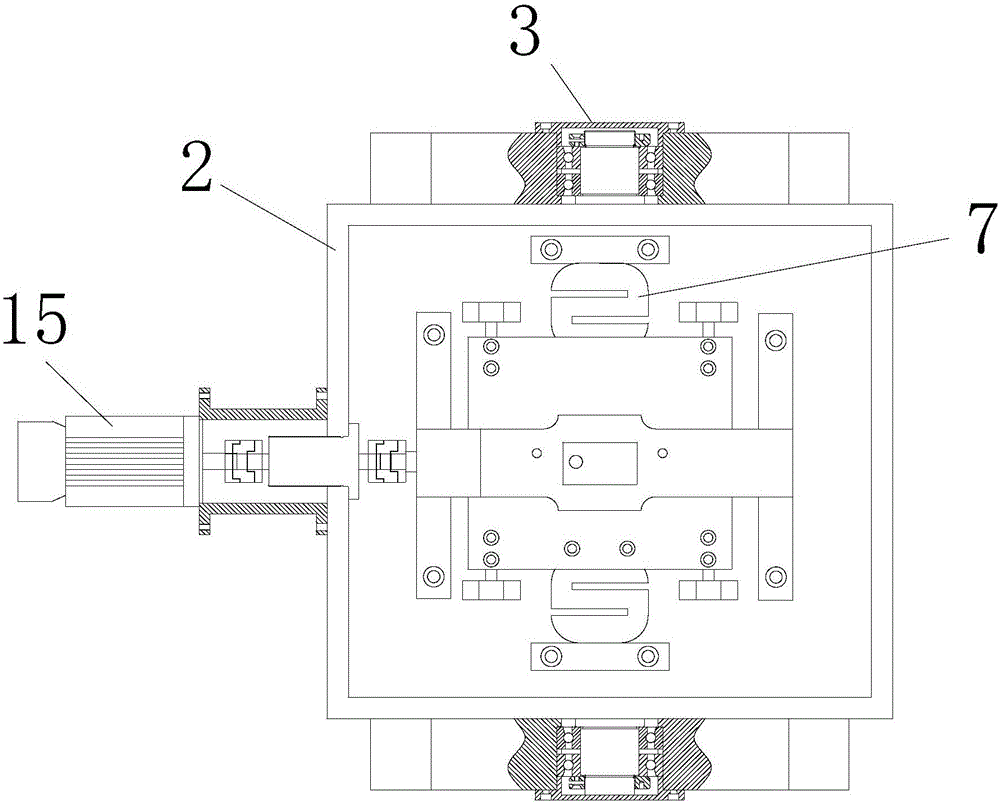

[0046] A sliding wear testing machine for a typical friction pair with variable gravity orientation, including a bracket 1, a vacuum box 2, an indexing plate 3, a loading mechanism 4, a sample fixture 5, a sample clamping mechanism 6, and a tester for testing fixed samples and moving parts. The friction sensor 7 of the friction force when the sample is rubbed, the vacuum box is installed on the support through the indexing plate, and the sample fixture and the sample clamping mechanism are installed in the vacuum box;

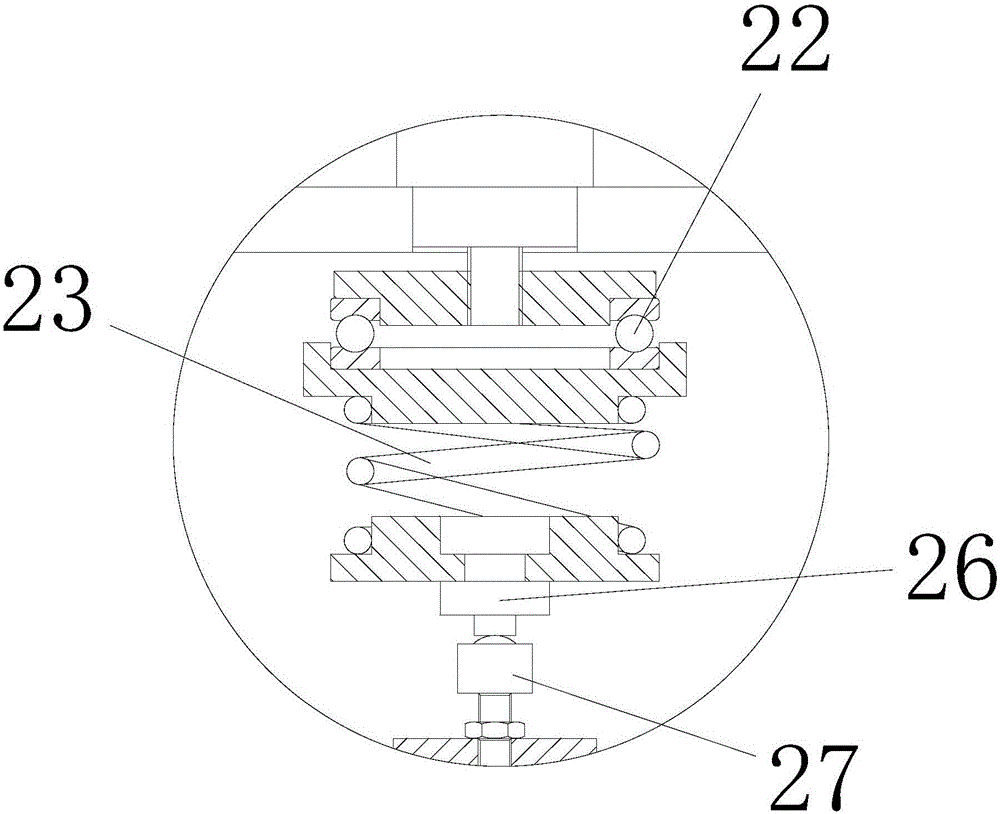

[0047] The sample fixture includes a clamping bracket 8, a jacket 9, a loading shaft 10, and an upper chuck 11 for clamping and fixing the sample. The jacket is fixed on the clamping bracket, and the loading shaft is connected to the jacket. Connected to the lower part of the loading shaft, the loading mechanism is connected to the loading shaft;

[0048] The sample clamping mechanism includes a sample mounting plate 12 for fixing the movable sample and a sampl...

Embodiment 2

[0070] A sliding wear test method of a typical friction pair with variable gravity orientation, comprising the following steps:

[0071] Vacuum the vacuum box, adjust the indexing plate so that the vacuum box is placed horizontally or at the required inclination angle, and the loading mechanism applies pressure to the sample fixture;

[0072] Start friction: the sample driving device drives the sample mounting plate to make the movable sample reciprocate relative to the fixed sample, thereby causing friction between the fixed sample and the movable sample. During the friction process between the fixed sample and the movable sample, the friction The force sensor detects the friction force when the fixed sample and the movable sample are rubbed;

[0073] After the set time, stop the friction between the fixed sample and the movable sample, and remove the fixed sample and the movable sample;

[0074] Load a new fixed sample to be tested and a movable sample to be tested, vacuumi...

Embodiment 3

[0081] The vacuum box is evacuated, and the loading mechanism applies alternating pressure to the sample holder;

[0082] Start friction: the sample driving device drives the sample mounting plate, so that the movable sample moves back and forth relative to the fixed sample, so that friction occurs between the fixed sample and the movable sample, during the friction process between the fixed sample and the movable sample;

[0083] After the set time, stop the friction between the fixed sample and the movable sample, and remove the fixed sample and the movable sample;

[0084] When it is necessary to carry out tests at different inclination angles, load new fixed samples and movable samples to be tested respectively and adjust the indexing plate so that the vacuum box is at the required inclination angle, and then proceed according to the above process friction;

[0085] Load a new fixed sample and a movable sample to be tested, the vacuum box is evacuated, and the loading mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com