Hierarchical summation method for predicting hob abrasion through abrasion ratio consumption indexes

A technology of wear and hob, applied in complex mathematical operations, mining equipment, earthwork drilling, etc., can solve problems affecting applicability and other issues, achieve the effect of rationally arranging construction progress, improving shield tunneling efficiency, and enriching research results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

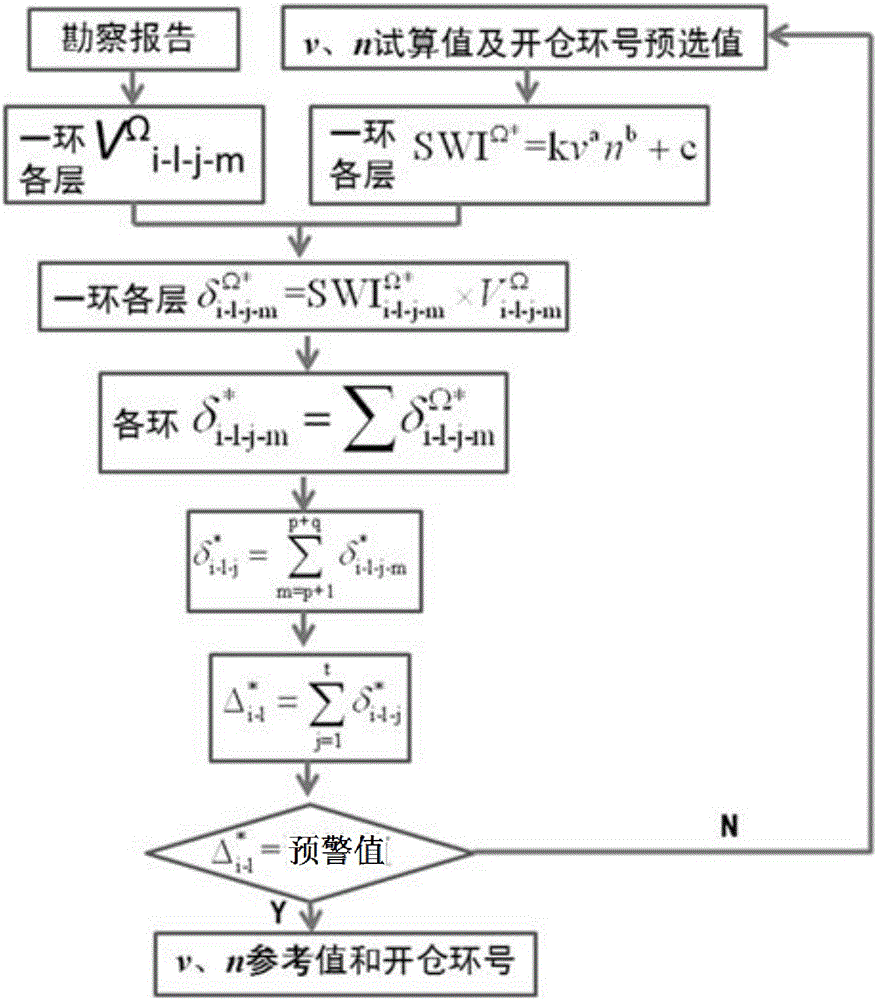

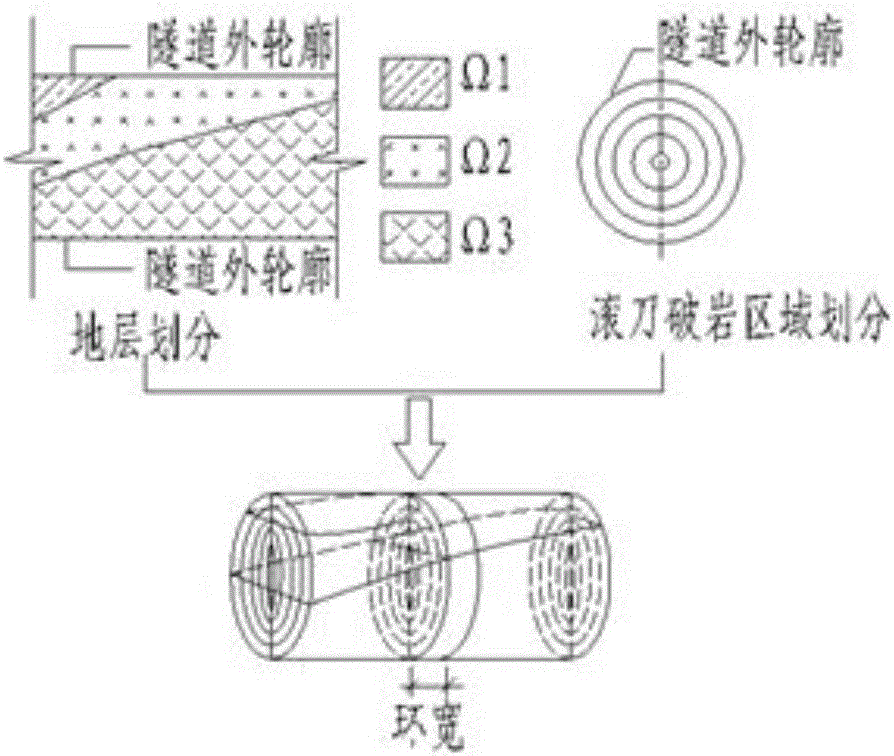

[0039] The present invention uses the wear specific consumption index to predict the layered summation method of hob wear amount, comprising the following steps:

[0040] step one:

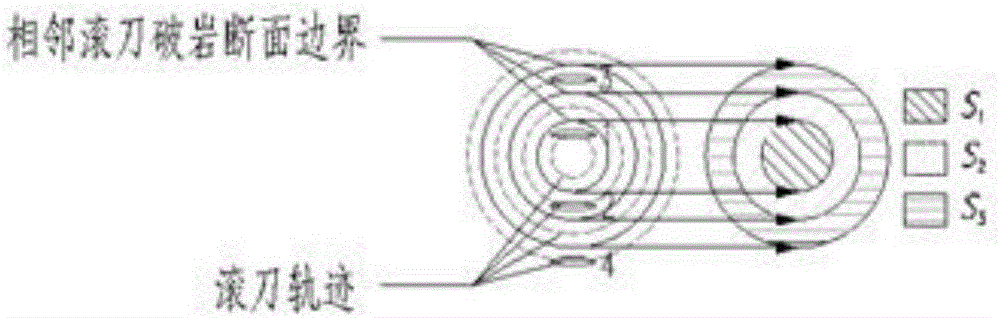

[0041] The average value of tunneling parameters (v i-l-j-m ,n i-l-j-m , F i-l-j-m , T i-l-j-m ,P i-l-j-m ), where v is the propulsion rate, n is the rotational speed of the cutterhead, F is the effective thrust, T is the torque, P is the pressure of the earth bin, i is the serial number of the hob, l is the replacement sequence of the hob, and j is the life span of the hob The measurement order of position opening, m is the ring number;

[0042] Step two:

[0043] Carry out the wear measurement of the hob cutter ring, and record the wear increment δ of each hob during each opening inspection or tool change Ω i-l-j , when the hob rock-breaking formation is a composite formation, it is recorded as δ Δi-l-j , Ω is the serial number of the hob rock-breaking formation;

[0044] Step three: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com