Tube type backflow incense manufacturing device

A technology for manufacturing devices and backflow incense, which is applied to floor fabrics, religious or sacrificial utensils, household utensils, etc., and can solve problems such as thick walls of incense bodies, easy generation of harmful gases, and insufficient oxygen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

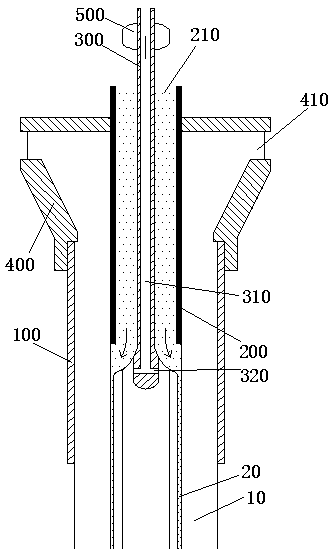

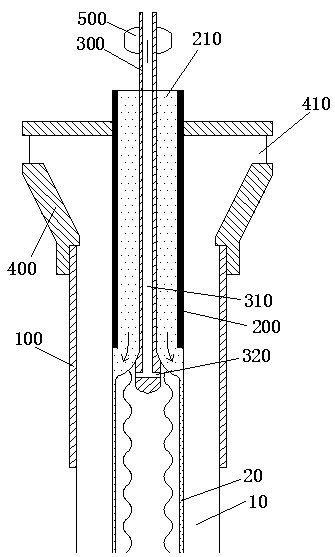

[0014] In this example, see figure 1 , the tube-type backflow incense manufacturing device includes a main nozzle 100 and a sub-nozzle 200, the root of the main nozzle 100 is provided with an end cover 400, and the end cover 400 is provided with a feed port 410, and the sub-nozzle 200 is coaxially arranged inside the main nozzle 100, the nozzle of the sub-nozzle 200 is located inside the nozzle of the main nozzle 100, and the root of the sub-nozzle 200 passes through the end cover 400 to form a feed port 210, the feed port 210 is connected to an air blowing device, the sub-nozzle 200 is coaxially provided with a centrifugal packing shaft 300, the centrifugal packing shaft 300 is axially provided with a feed pipe 310, and the centrifugal packing shaft One end of 300 is set at the feed port 210, and the other end is set at the outside of the nozzle of the sub-nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com