Hollow plate beam spiral reinforcement forming machine

The technology of a hollow slab beam and rib forming machine, which is applied in the field of forming machines, can solve the problems of high cost and high market price of finished spiral ribs, and achieves the effects of convenient use, convenient and fast processing and production, and reducing the delay time of intermediate transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

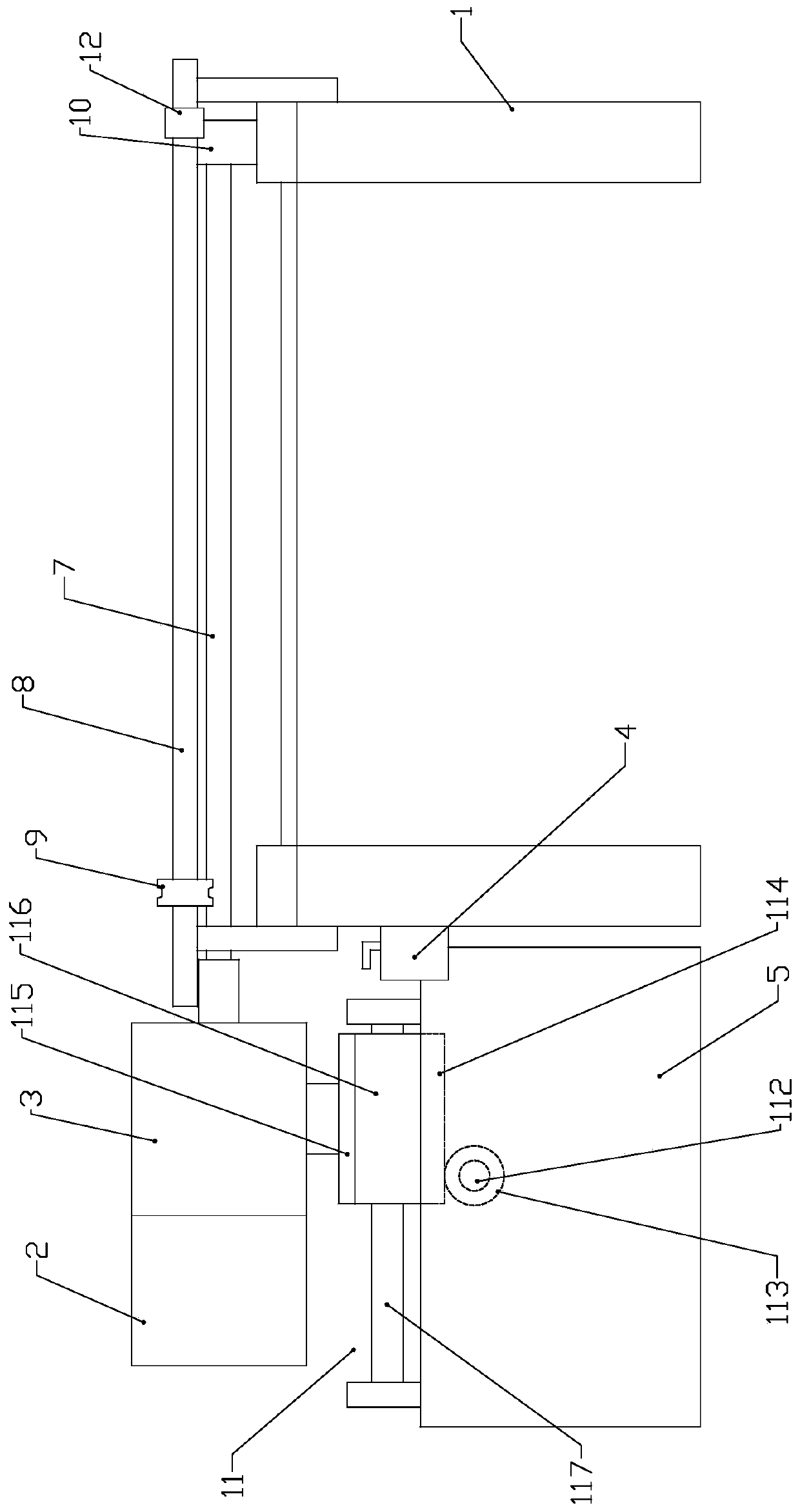

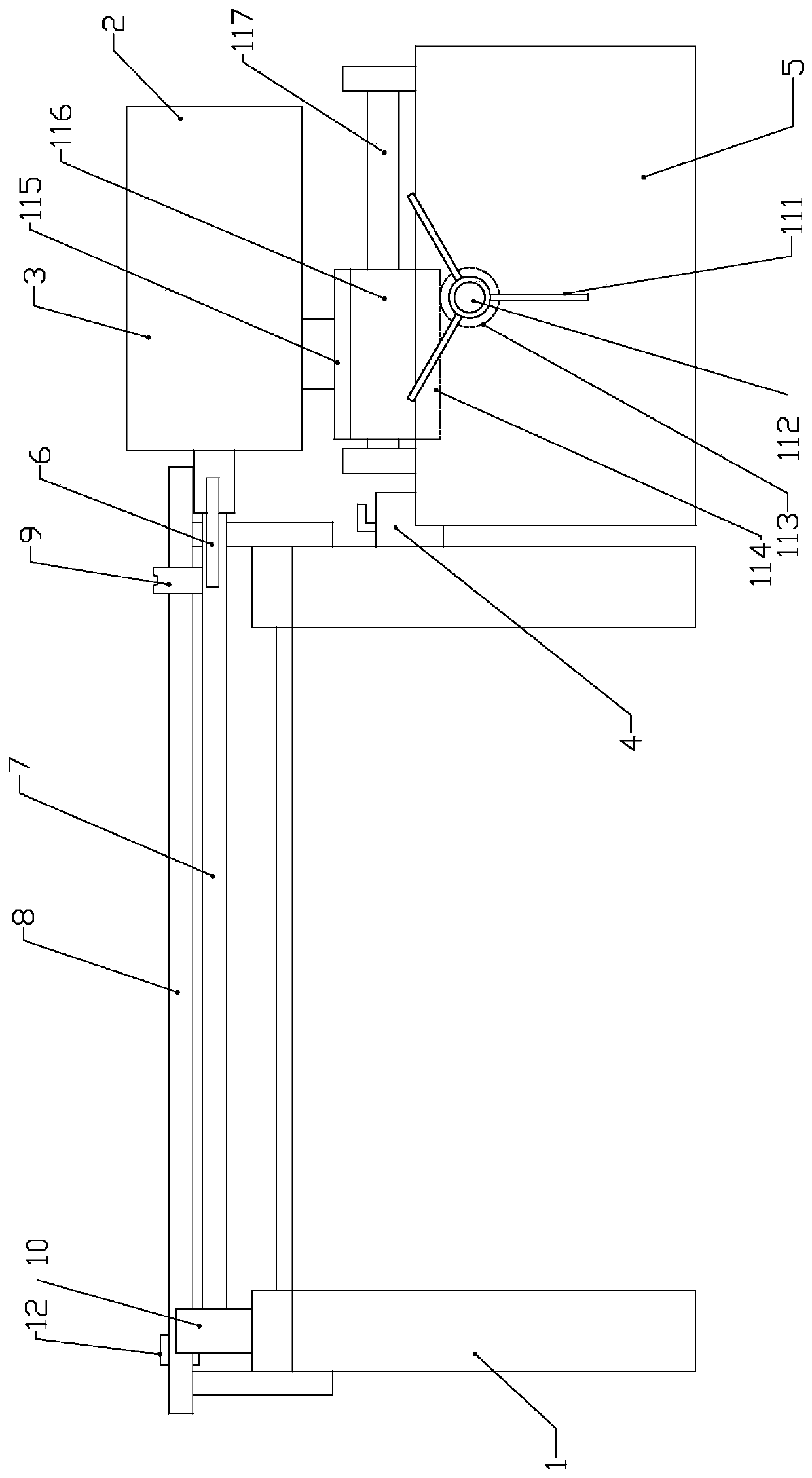

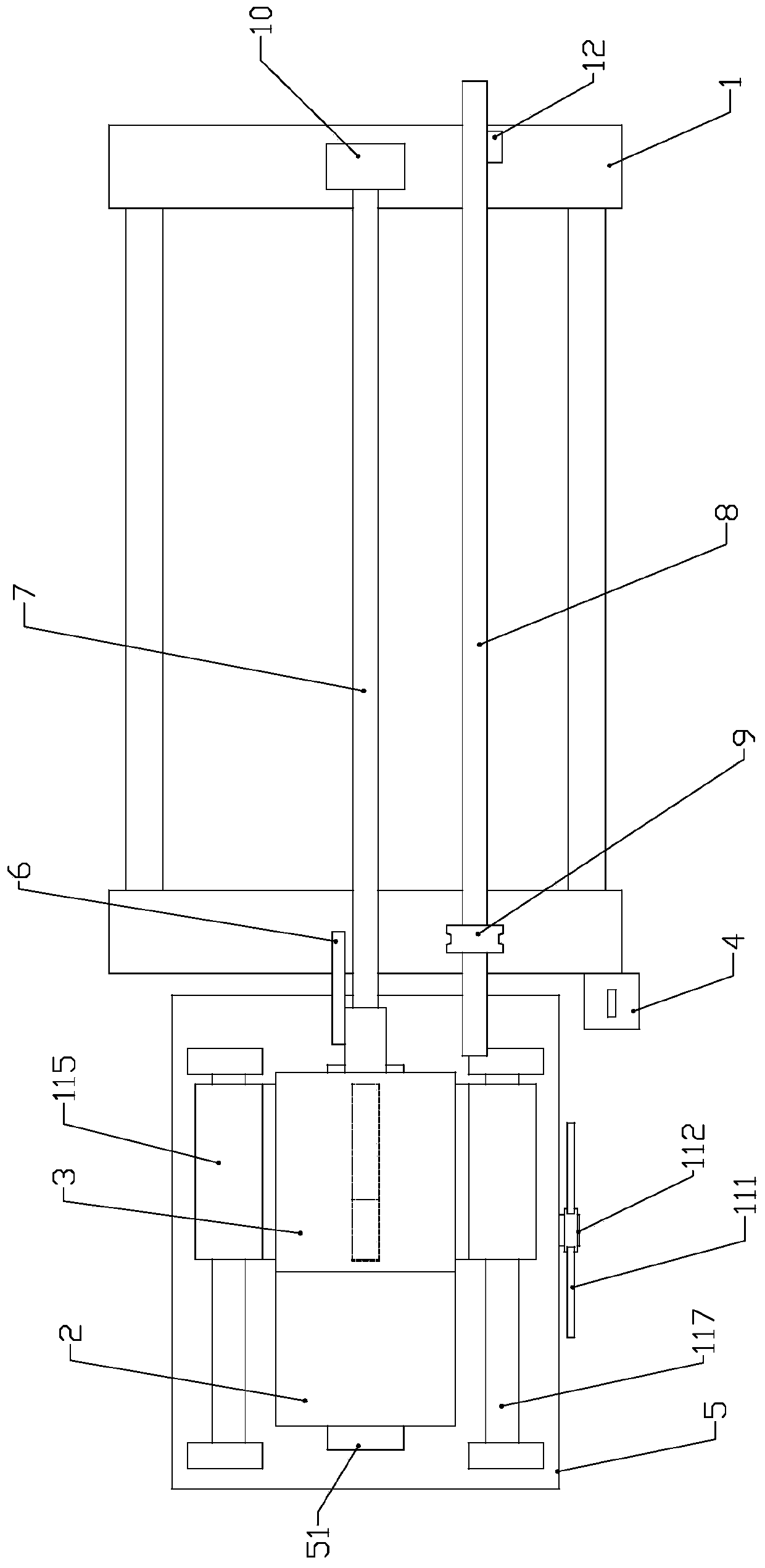

[0018] Refer to the attached figure 1 To attach Figure 4 The hollow slab beam spiral rib forming machine of the present invention will be described in detail below.

[0019] The hollow slab beam spiral bar forming machine of the present invention has a structure comprising a fixed bracket 1, a motor 2, a reducer 3, a reversing switch 4, a frame 5, a steel bar retainer 6, a bending shaft 7, a force transmission shaft 8, a rolling The wheel 9, the bearing seat 10 and the motor moving drive mechanism 11, the motor 2 is connected to the reducer 3, the output shaft of the reducer 3 is connected to the bending shaft 7, and the other end of the bending shaft 7 is connected to the bearing seat 10 , the bearing block 10 is fixed on the upper part of the distal end of the fixed bracket 1, the bending shaft 7 and the force transmission shaft 8 are respectively located on the upper part of the fixed bracket 1, and the two are arranged obliquely from front to back, and the transmission s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com