A process method for vacuum infusion molding of composite material thick parts

A technology of vacuum infusion and molding process, which is applied in the direction of household components, applications, household appliances, etc. It can solve the problem of whitening under the flow channel, achieve quality resolution, ensure infusion efficiency, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

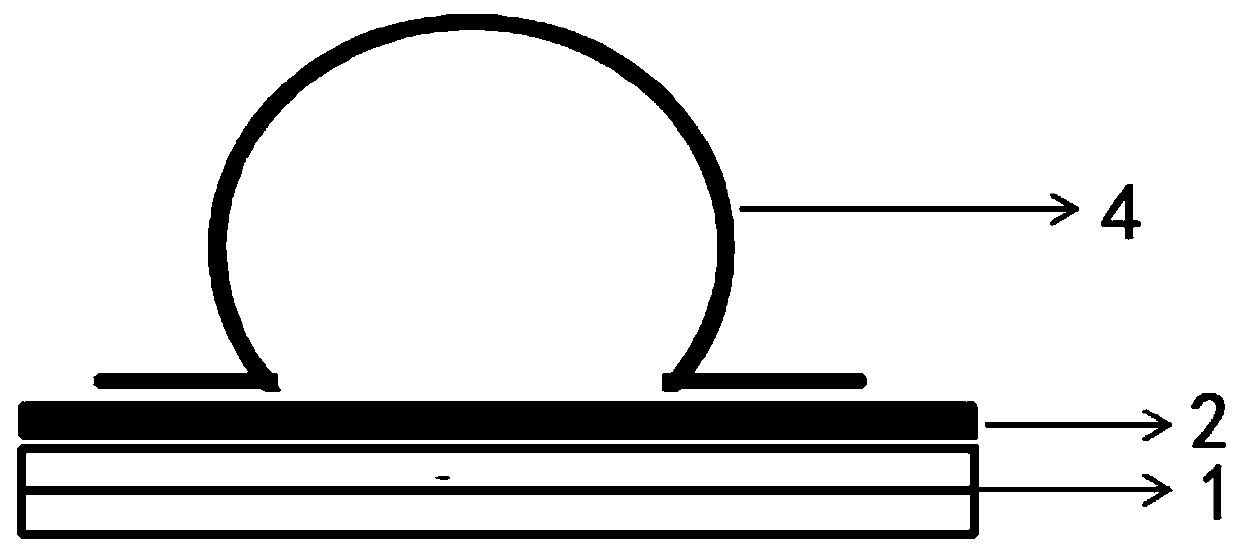

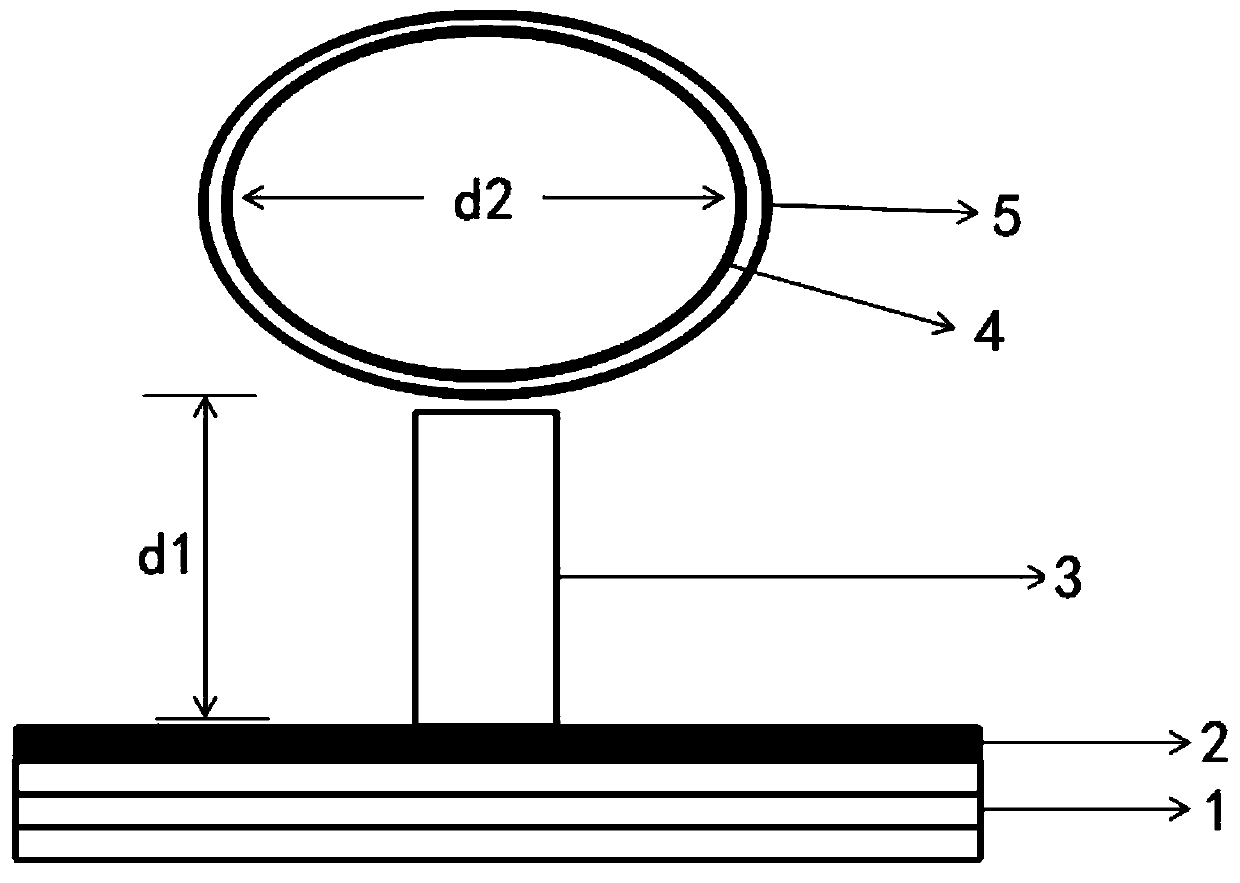

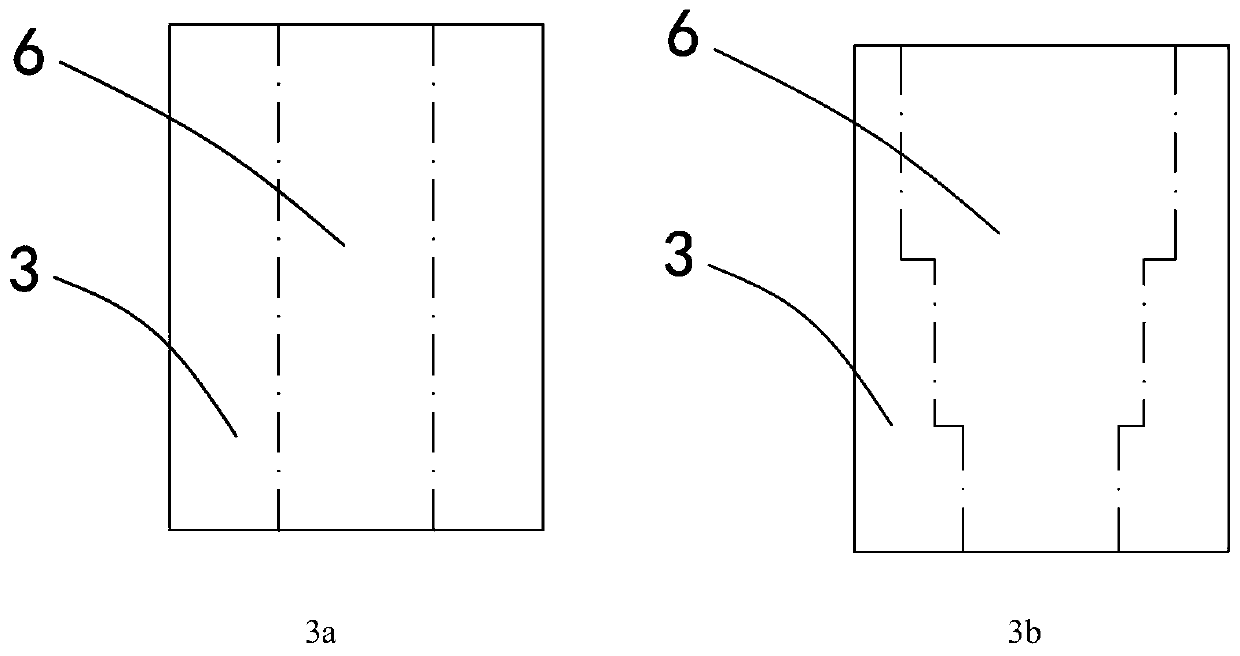

[0033] The embodiment of the present invention firstly provides a vacuum infusion molding process for composite material thick parts, which specifically includes the following steps: (1) laying a reinforced glass fiber fabric layer on the mold according to the product structure design; (2) laying a reinforced glass fiber fabric layer on the reinforced glass The surface of the fiber fabric layer is laid with a porous isolation film and a release cloth (not shown in the figure); (3) a diversion net is placed on the surface of the isolation film; (4) a separation material, a diversion tube is placed on the diversion net, and the diversion The surface of the tube is covered with diversion material, and the diversion material is used outsid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com