Concrete cast-in-place pile top elevation control device and using method thereof

A control device and technology of cast-in-place piles, which are used in sheet pile wall, foundation structure test, construction, etc., can solve the problems of high operator requirements, large interface recognition errors, and inability to guarantee measuring hammers, etc., and reduce chisel removal. Difficulty, guaranteed perfusion height, and the effect of improving flexibility and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

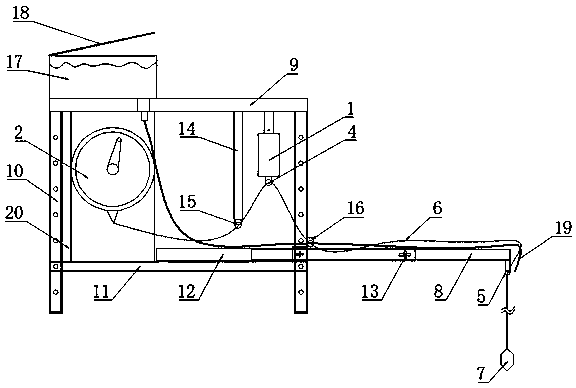

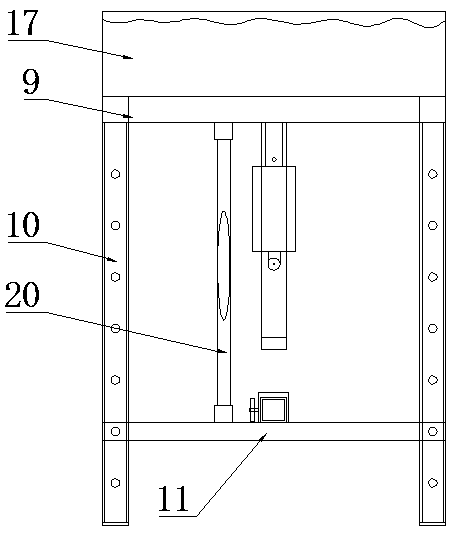

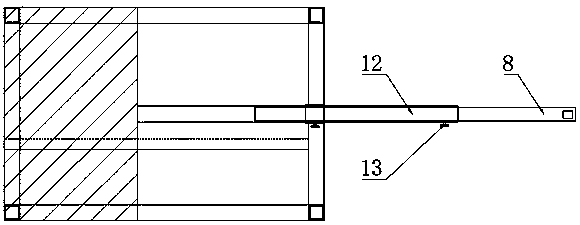

[0035] This embodiment provides a pile top elevation control device for concrete pouring piles, including a bracket, a tension sensor switch 1, a wire winder 2, a winding motor 3 that drives the wire winder 2 to rotate, a first fixed pulley 4, and a second fixed pulley 5. A scaled traction rope 6, an alarm device and a buoyancy detection hammer 7; the bracket includes a height-adjustable frame body and a horizontally telescopic and fixed horizontal cantilever 8 arranged on the frame body; the tension sensor switch 1 is used for closing the alarm The circuit where the device is located is installed on the frame with the end facing down, and the first fixed pulley 4 is installed on the end; the winding device 2 and the winding motor 3 are all installed on the frame; the second fixed slide 5 is installed on the The transverse cantilever 8 stretches out from the end of the frame body; the traction rope 6 is wound on the wire winder 2, and is drawn from the wire winder 2, passes thr...

Embodiment 2

[0057] This embodiment also provides a method for using the control device for the top elevation of concrete pouring piles, which is implemented based on the control device for the top elevation of concrete pouring piles shown in Example 1, including the following steps,

[0058] S1, hang the buoyancy detection hammer 7 on the preset elevation position of the cast-in-place pile to be processed, the tension sensor switch 1 detects that the pulling force of the buoyancy detection hammer 7 on the traction rope 6 is greater than the trigger pull, the tension sensor switch 1 is in the open state, and the alarm device is located circuit disconnected;

[0059] S2, carry out concrete pouring, until the interface between the laitance layer 101 and the concrete layer 102 is raised to the height of the buoyancy detection hammer 7, the tension sensor switch 1 is closed after reaching the trigger tension, the circuit where the alarm device is located is closed, and the alarm device sends ou...

Embodiment 3

[0064]This embodiment also provides a method for using the control device for the top elevation of concrete pouring piles, which is implemented based on the control device for the top elevation of concrete pouring piles shown in Example 1, including the following steps,

[0065] S1, hang the buoyancy detection hammer 7 on the pile opening of the cast-in-situ pile to be processed, the tension sensor switch 1 detects that the pulling force of the buoyancy detection hammer 7 on the traction rope 6 is greater than the trigger tension, the tension sensor switch 1 is in the open state, and the circuit where the alarm device is located disconnect;

[0066] S2, put the buoyancy detection hammer 7 down along the cast-in-situ pile to be processed until the buoyancy detection hammer 7 touches the bottom of the pile, the tension sensor switch 1 is closed after reaching the trigger tension, the circuit where the alarm device is located is closed, and the alarm device sends out an alarm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com