[0003] Although concrete pouring piles are used more and more in

construction engineering, the control of the top elevation of concrete pouring piles has always been one of the difficulties in the construction of concrete pouring piles. , For example, if the amount of admixture is too high or the

water consumption exceeds the standard, the concrete

slump will be too large or even segregated, and laitance will appear. The strength of cast-in-place piles cannot meet the standard requirements of cast-in-place piles. Therefore, in order to avoid the influence of laitance layer, when controlling the top elevation of cast-in-place piles, it is often necessary to overfill the specified height on the set height of cast-in-place piles. Generally, cast-in-place piles need to exceed the height It is more than 500mm, and the laitance part will be chiseled off after the concrete is solidified. Therefore, if the top elevation is set too low, the laitance layer cannot be avoided, and the final pile body will be unqualified. If the top elevation is set too high, It will cause waste of concrete and difficulties in subsequent construction (

cutting away the laitance layer and the concrete exceeding the design height of the cast-in-place pile)

[0004] At present, in the process of controlling the superfill height, the difficult problem is how to accurately identify the interface between the concrete and the laitance, so as to determine the actual height of the concrete liquid level. The traditional construction method is to manually lift the heavy object through the measuring

rope Placed at the set elevation position of the cast-in-place pile or bamboo pole penetration, rely on the staff's feel or experience to judge whether the heavy object has a pulling force on the human hand or whether there is concrete pushing the bamboo pole to identify the interface between the concrete and the laitance. The method has high requirements for the operators, and it cannot guarantee that the heavy objects or the bottom of the bamboo poles are accurately located at the set elevation position of the cast-in-place pile, so the recognition error of the interface is relatively large. At the same time, due to the complex environment of the construction site, these methods are limited The

operating environment has a greater

impact, which further reduces the recognition accuracy

[0005] The No. 201310141689.5 application of the China Construction Eighth Bureau No. 2 Construction Co., Ltd. on 2013-04-23 is a patent with the

subject name of an

underwater cast-in-situ pile concrete overfill

detector and its method of use, which discloses a method for identifying laitance and concrete The interface device and method, but this device is suitable for

underwater cast-in-situ piles, not completely suitable for ordinary cast-in-place piles, and this device is based on the completion of overfilling of cast-in-place piles, and then through the

detector to determine whether the overfilling has exceeded Whether the height of

irrigation meets the set elevation is only a confirmation and

verification after over-

irrigation, and the height of over-

irrigation cannot be effectively controlled in advance, and the operation of this device and method is relatively complicated, which is not conducive to improving efficiency

[0006] Through further analysis, among the known detection methods, judgments are mainly made in the form of mechanical detection, and these mechanical detection methods basically rely on manual operation and are greatly affected by the external environment, so there is no one that is more accurate. Accurate and effective methods are used to solve the above problems, but most construction companies can only ensure the quality of piles by increasing the top elevation on the basis of mechanical methods, which not only wastes resources but also increases costs

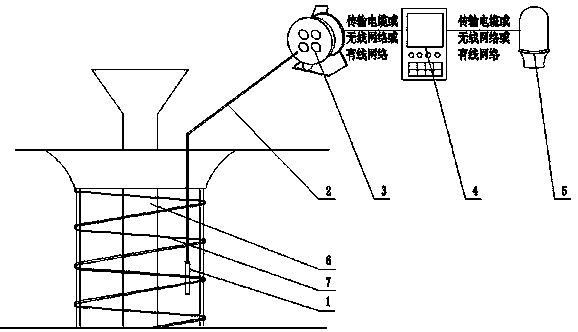

[0007] In addition, according to the requirements of the construction specification, in order to ensure the quality of concrete pouring when pouring pile concrete, it is required that the guide

pipe be buried in the concrete for 3-6m during pouring, and the height of the concrete in the guide

pipe will be higher than The concrete liquid level in the pile, the part of the concrete that is higher than the concrete liquid level in the pile is defined as the remaining material of the feed

pipe, this part of the remaining material will further increase the height of the cast-in-place pile, resulting in waste of materials, and the enterprise basically does not need to pay attention to the pile during

processing. There is no treatment for the strength of the concrete poured at the top, so after the pouring is completed, it will further increase the difficulties caused by the removal of the top of the cast-in-situ pile

Login to View More

Login to View More  Login to View More

Login to View More