A Concrete Pipe Pile Filling System That Can Improve the Quality of Finished Products

A concrete pipe pile and concrete technology, which is applied in the field of concrete pipe pile material filling system, can solve the problems that cannot be shaken and turned over, can not be removed by iron, and is prone to offset, etc., and achieves scientific and reasonable structure, safe and convenient use, and guaranteed efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

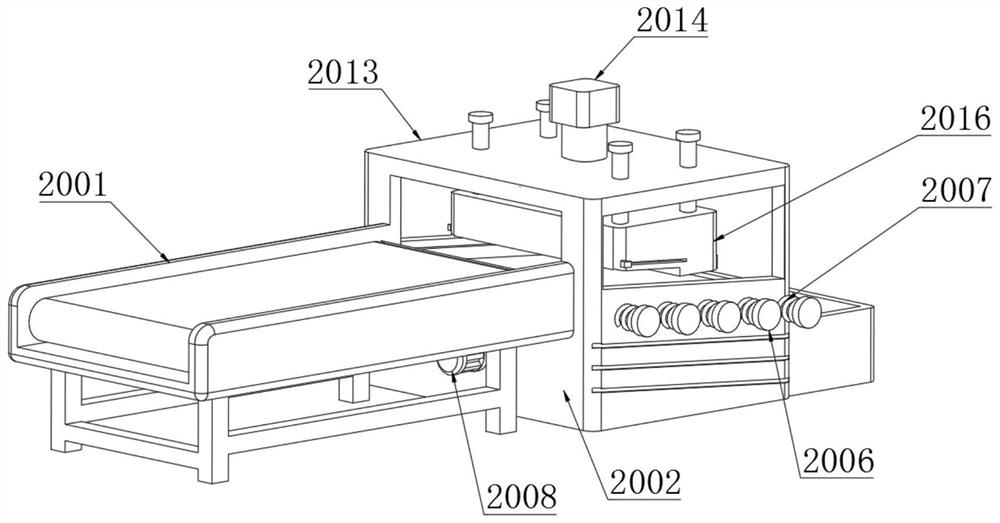

[0045] Example: such as Figure 1-14 As shown, the present invention provides a technical solution, a concrete pipe pile material pouring system that can improve the quality of finished products, including a deironing device 20 and a pouring device 200, and first removes iron in sand and stones through the deironing device 20 After being removed, it is sent to the pouring device 200, and the sand and stone are mixed into concrete through the pouring device 200, and poured into the pipe pile mold;

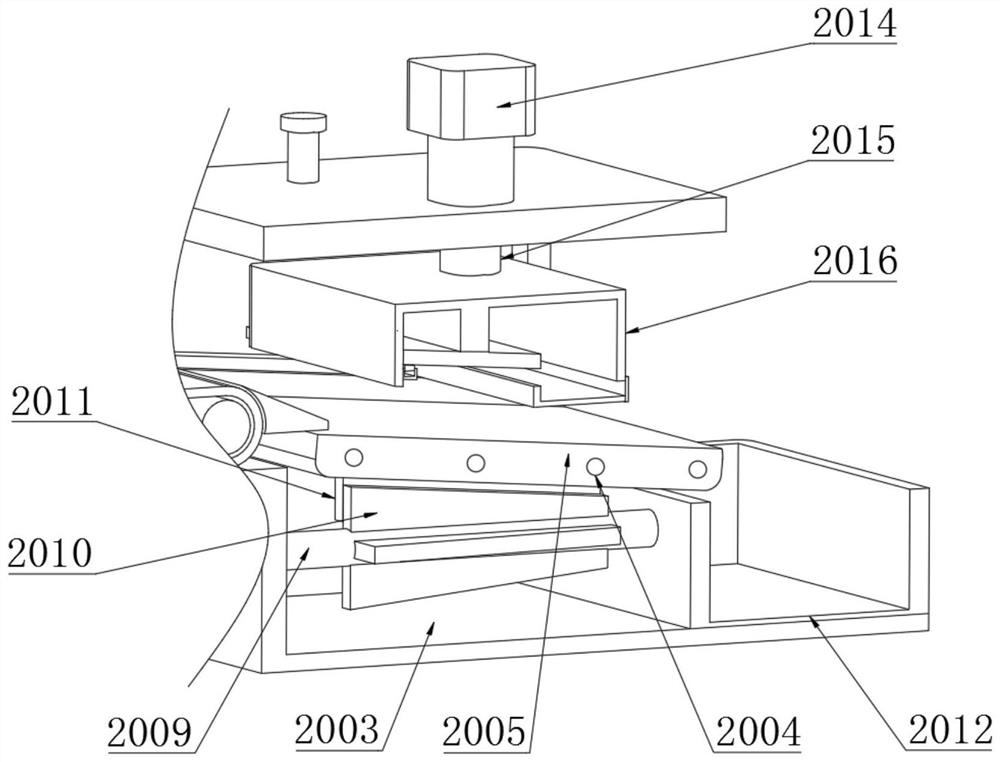

[0046] Iron removal device 20 comprises conveyor 2001, iron removal box 2002, magnetic suction chamber 2003, movable rod one 2004, blanking plate 2005, stopper 2006, tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com