Apex strip bundling device

A technology of bundling device and adhesive strip, which is applied in the directions of packaging, bundling materials, and parts of bundling machinery, etc., can solve the problems of incapable of bundling apex bales, and unable to drive the whole rotation of apex bales, etc. Utilization and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

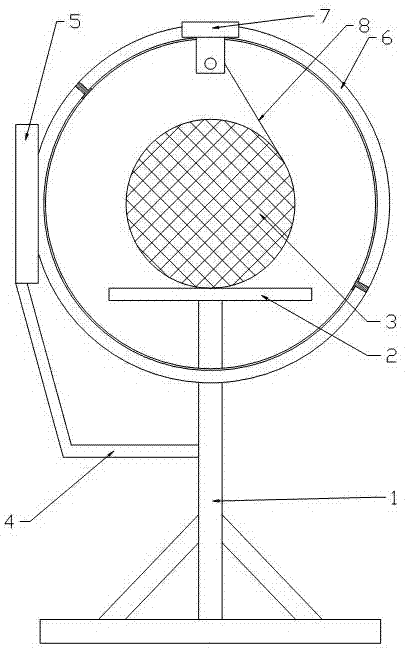

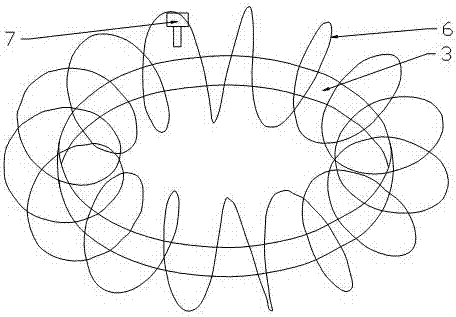

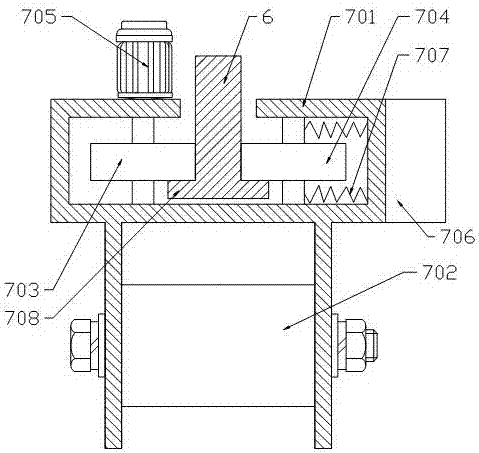

[0019] The apex bundling device of the embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: including a support frame 1 and a spiral baler, the support frame 1 includes 6 support rods distributed around the circumference, the support rods are provided with a platform 2 and a bracket 4, and a clip 5 is installed on the bracket 4; the spiral baler The device includes a flexible spiral frame 6 and a bundling head 7, the spiral frame 6 is in the shape of a cylindrical spiral, the bundling head 7 includes a frame 701, the two ends of the frame 701 are the strapping end and the power end respectively, and the frame 701 is T-shaped , the horizontal frame of the skeleton 701 is the power end, the vertical frame of the skeleton 701 is the bundling end, the bundling end rotates through the spiral rotation and is connected with the packing belt roller 702, the power end is installed on the horizontal frame, and the power end is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com