Patents

Literature

61results about How to "Bundled tightly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

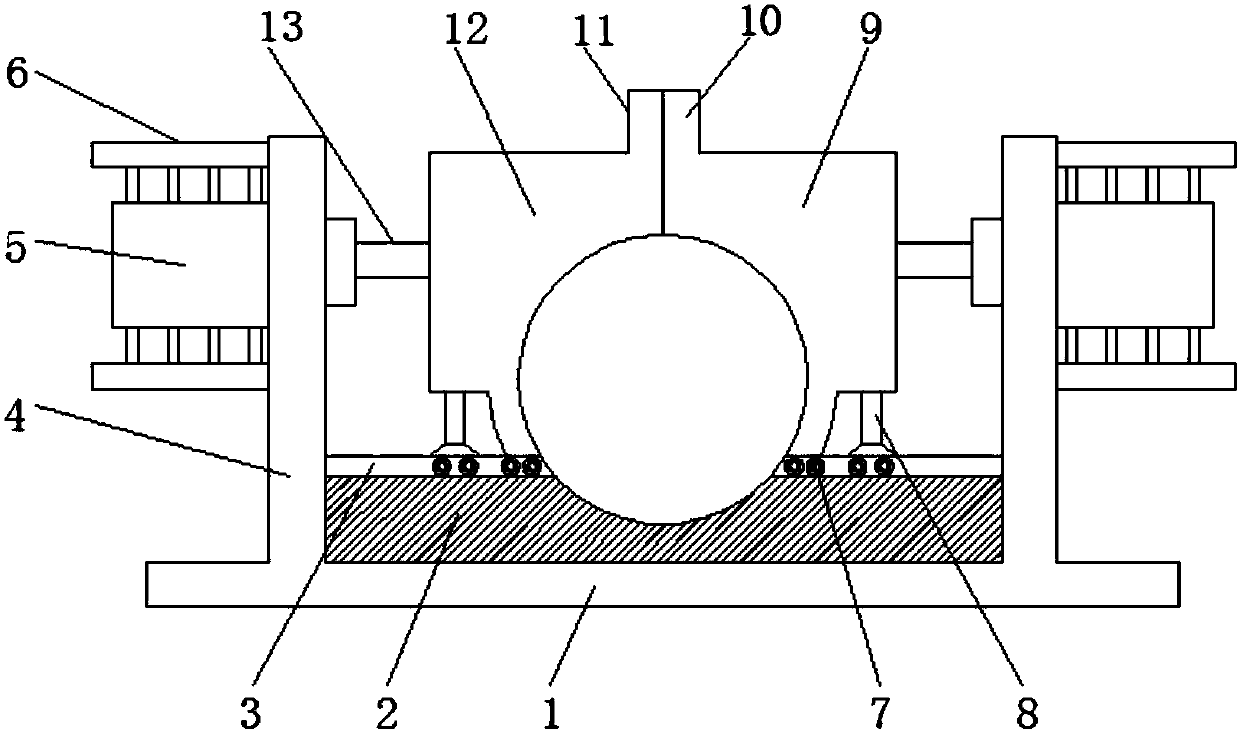

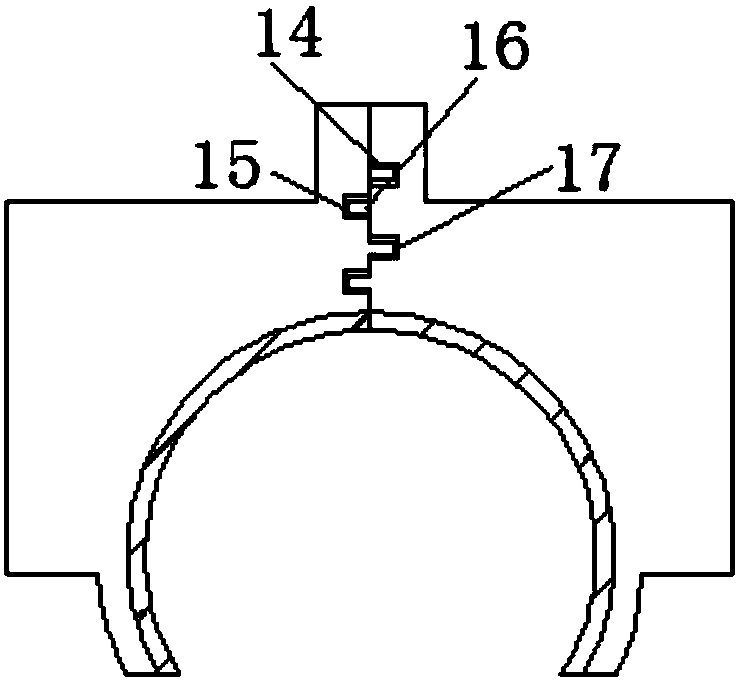

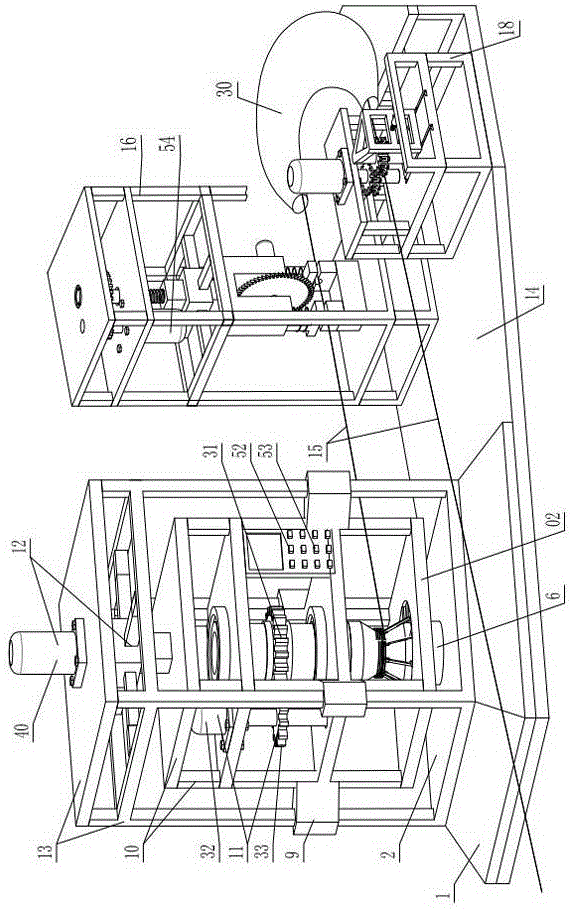

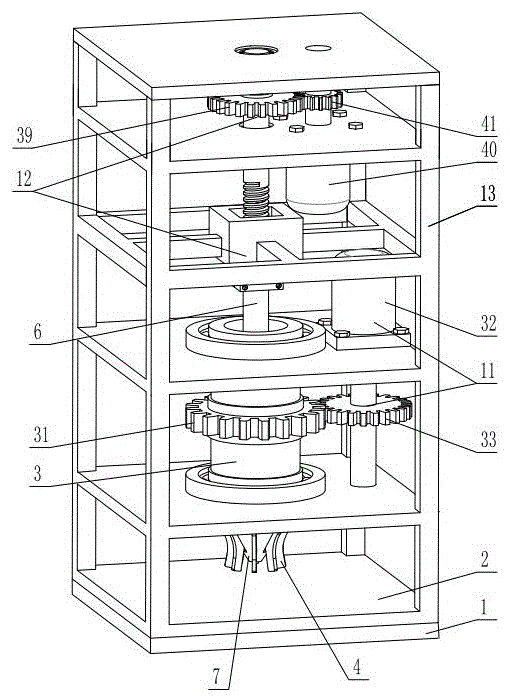

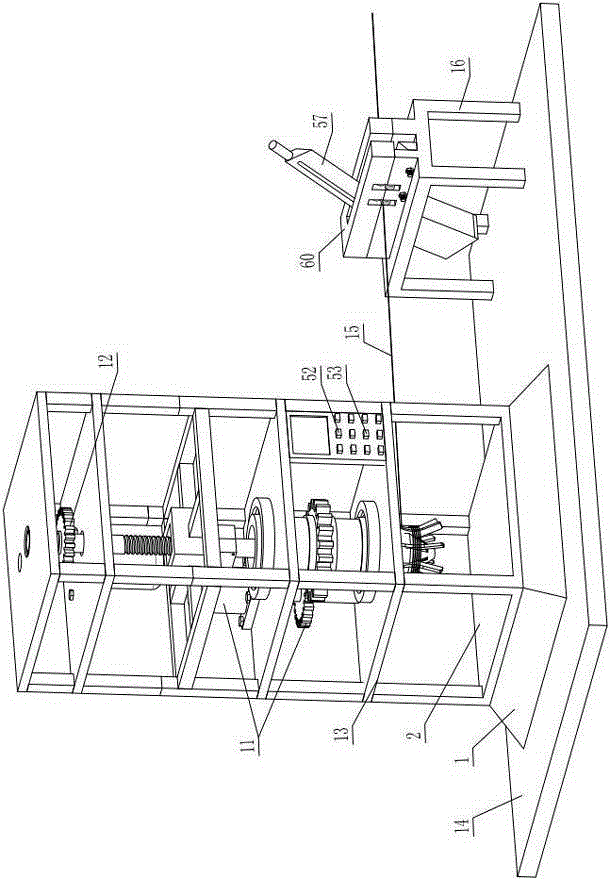

Quick and automatic building steel bar bundling device good in use effect

The invention discloses a fast automatic binding device for building steel bars with good use effect, comprising a binding base plate, a bottom binding bracket is embedded and welded on the binding base plate, and chute is symmetrically opened on both sides of the bottom binding bracket, The chute on both sides of the bottom strapping bracket is symmetrically connected with the first strapping side frame and the second strapping side frame through rollers respectively, and the bottom shells of the first strapping side frame and the second strapping side frame are welded with auxiliary supports steel frame, and the bottom of the auxiliary supporting steel frame is rotatably connected with the chute through rollers. In the present invention, firstly, by providing the first welding groove, the first welding bump, the second welding groove and the second welding bump, the steel bars for bundling can be cross-welded, so that the steel bars are fixed more tightly. It is firm and will not loosen. At the same time, it can automatically tighten the steel bars used for binding, making the steel bars more tightly bound, improving the quality of the binding, and increasing the competitiveness of the market.

Owner:CHENGDU KECHUANGGU TECH CO LTD

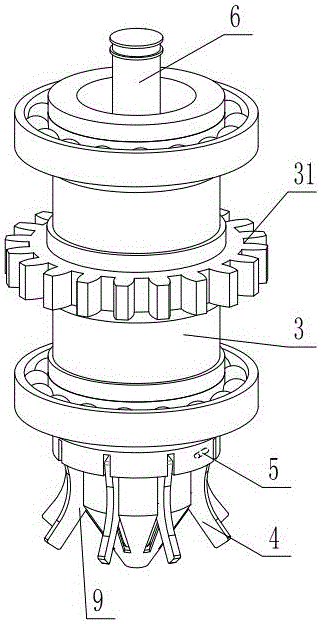

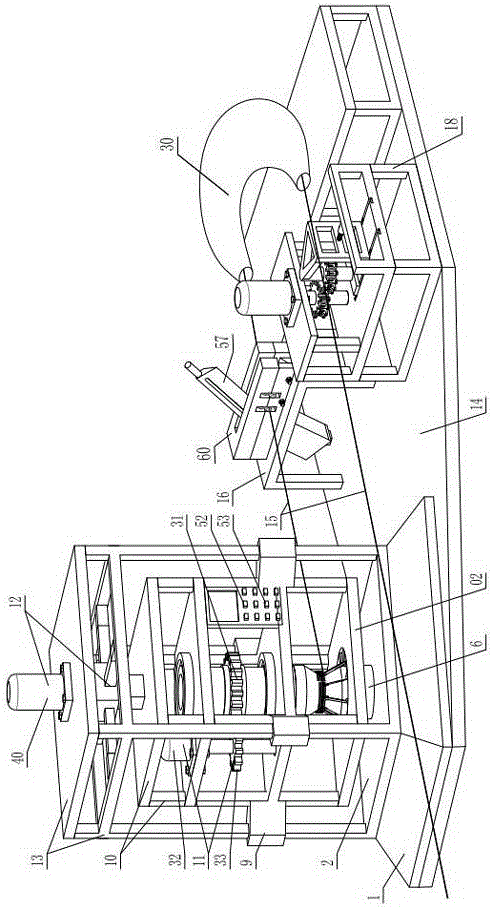

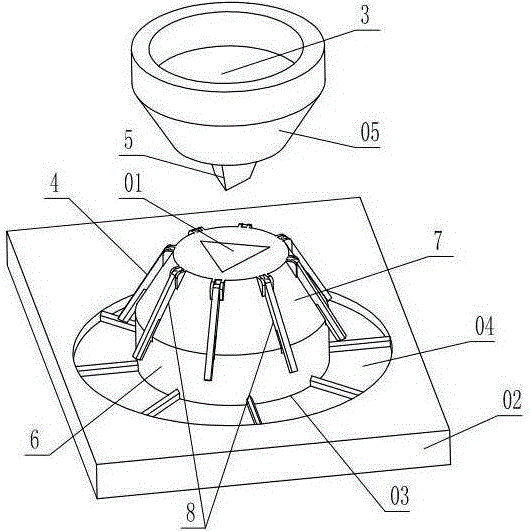

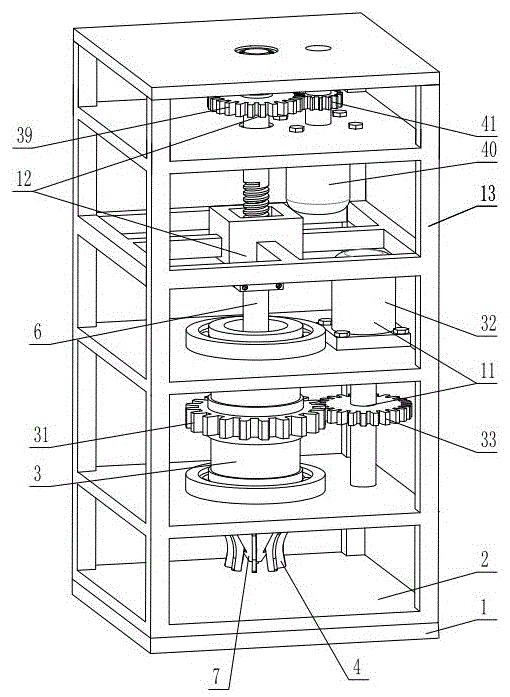

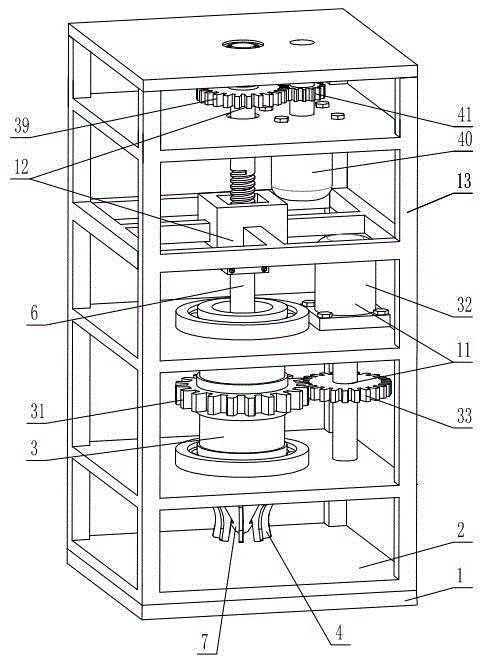

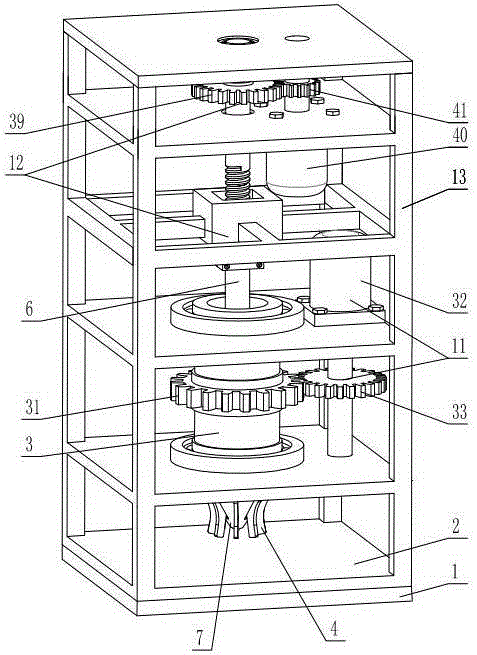

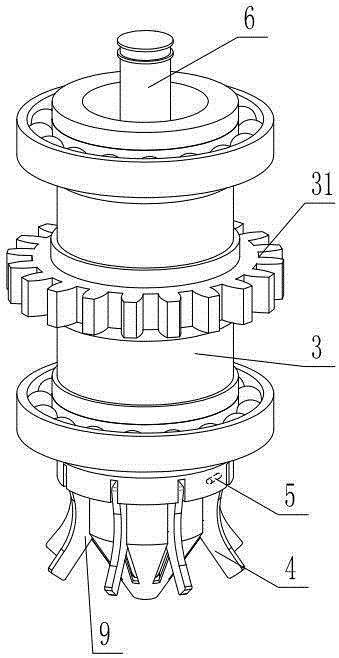

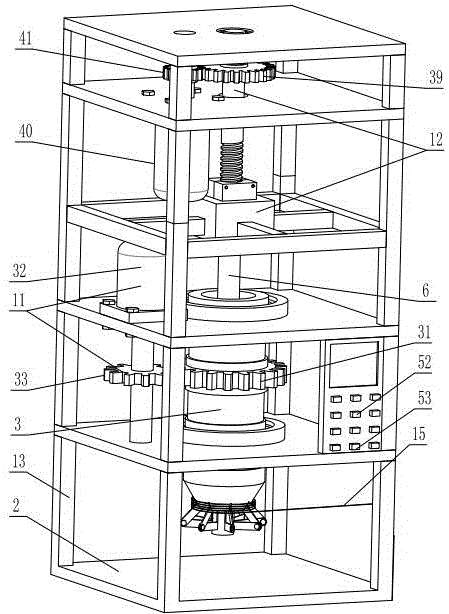

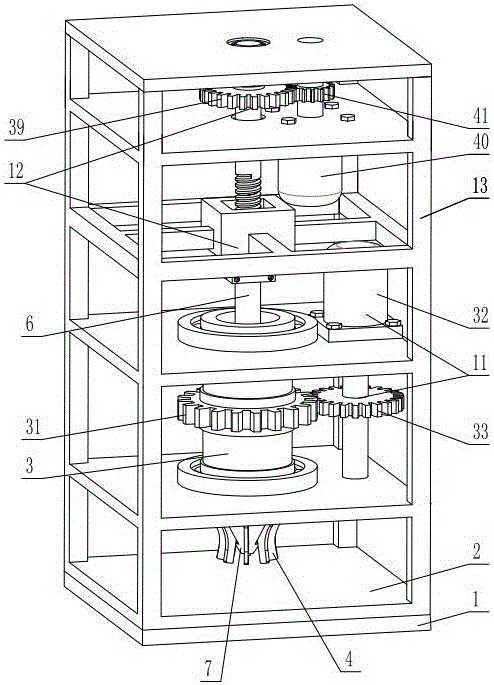

Power cable take-up device

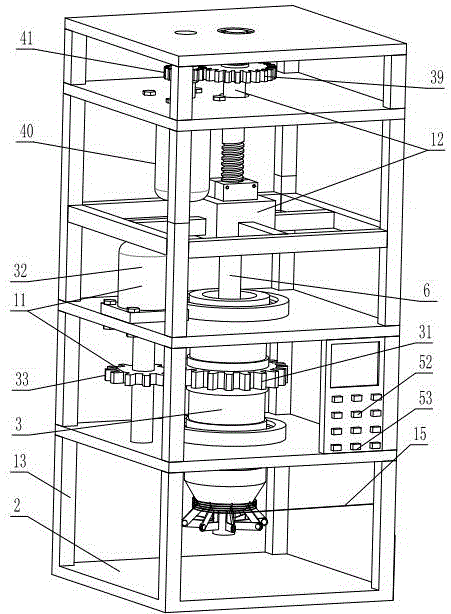

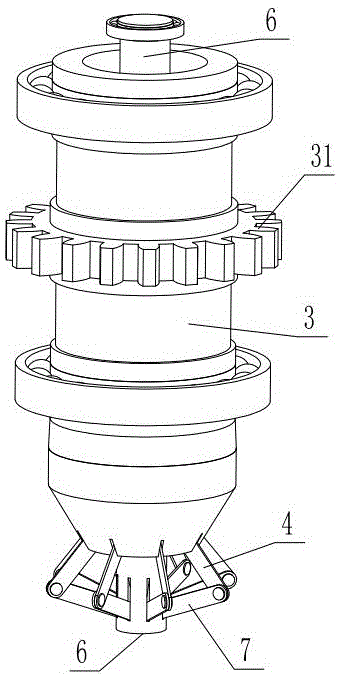

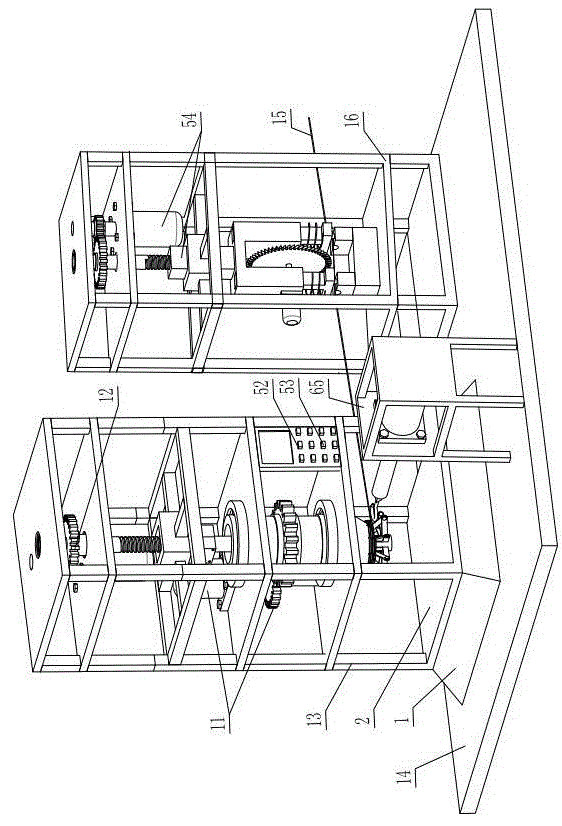

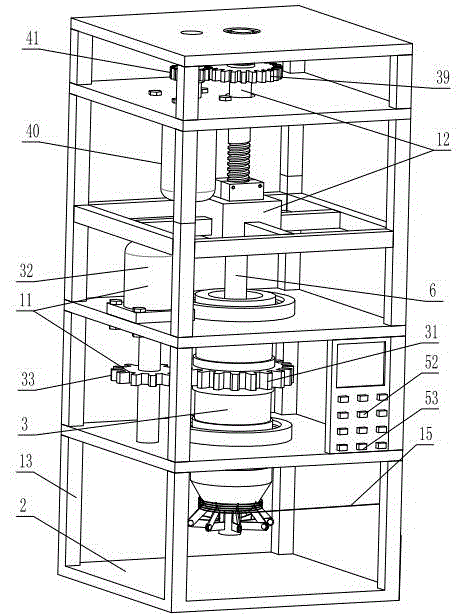

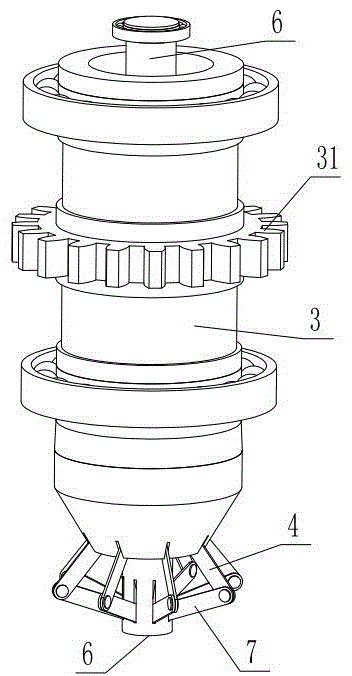

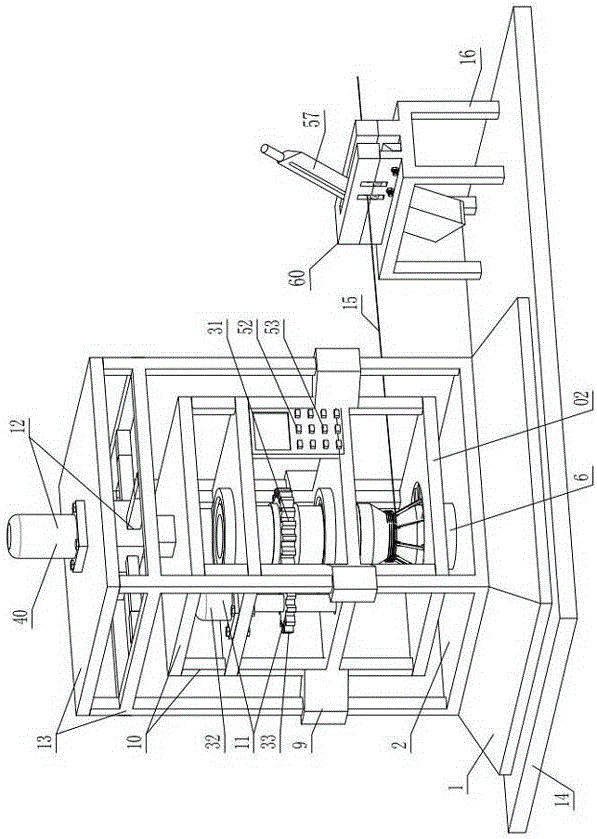

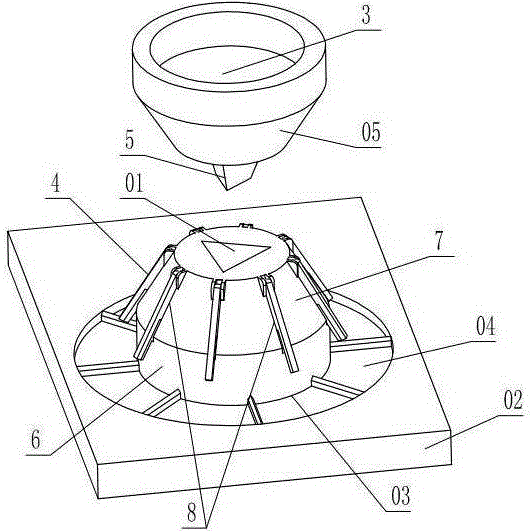

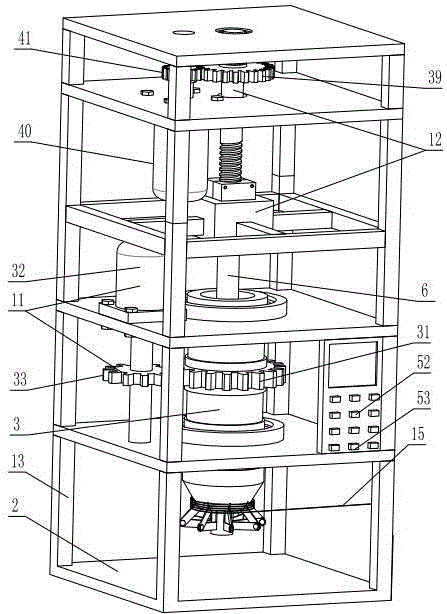

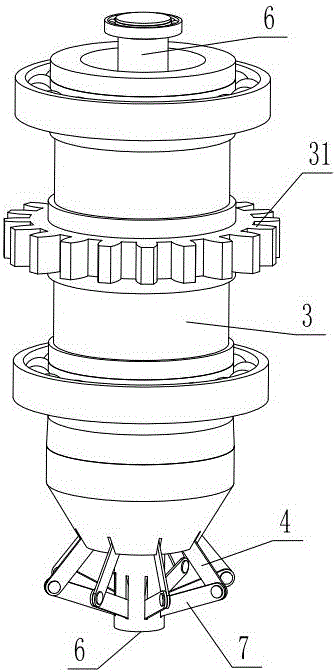

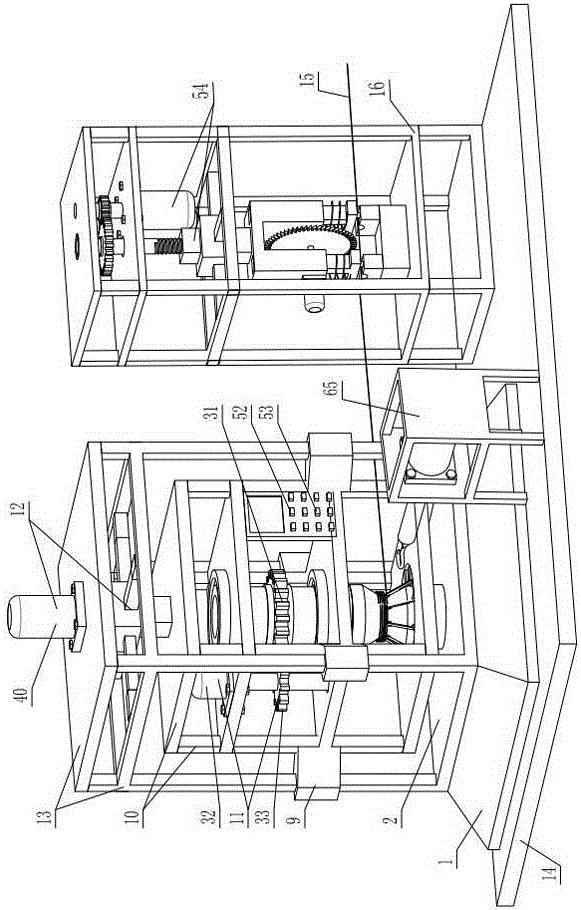

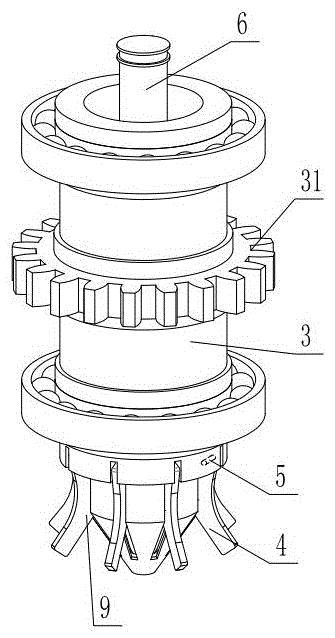

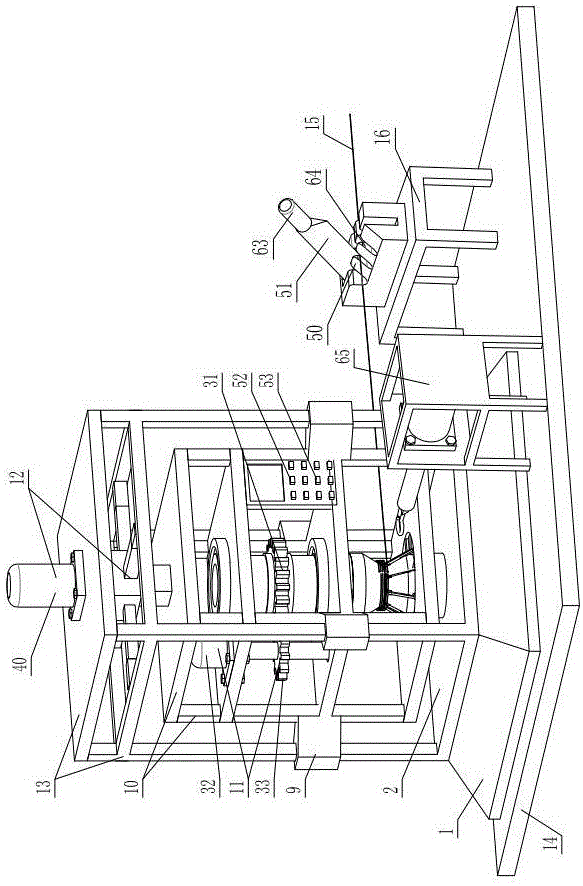

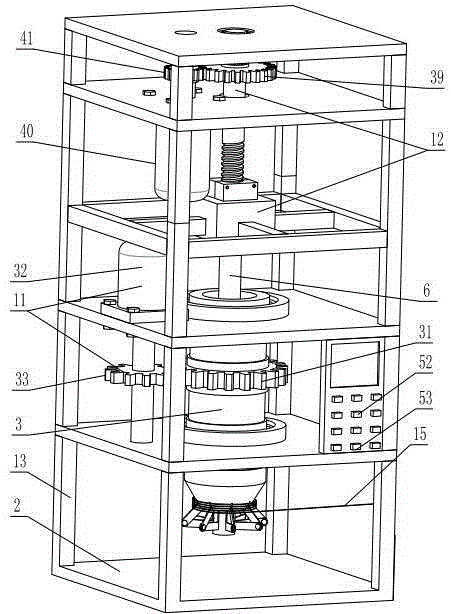

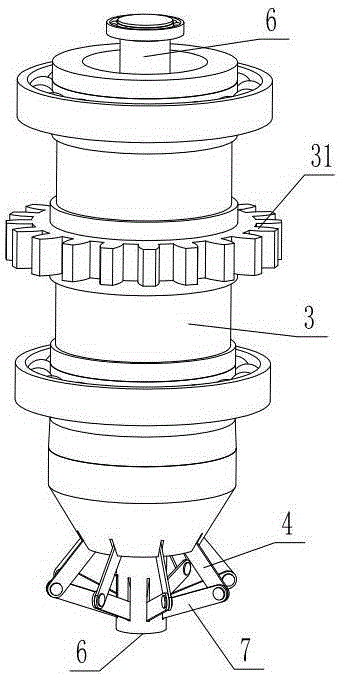

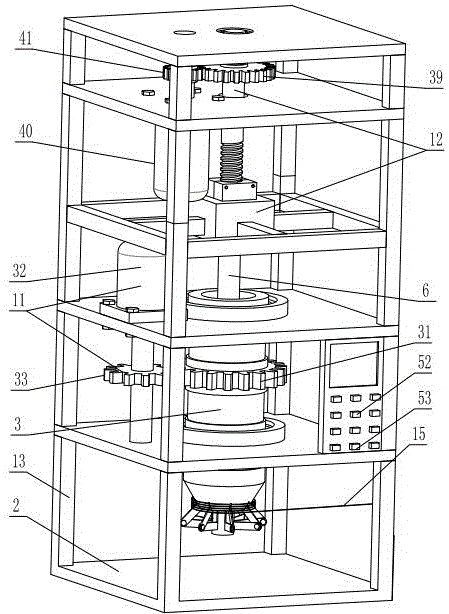

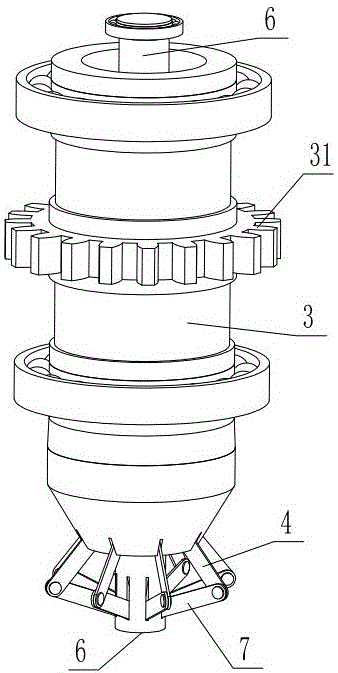

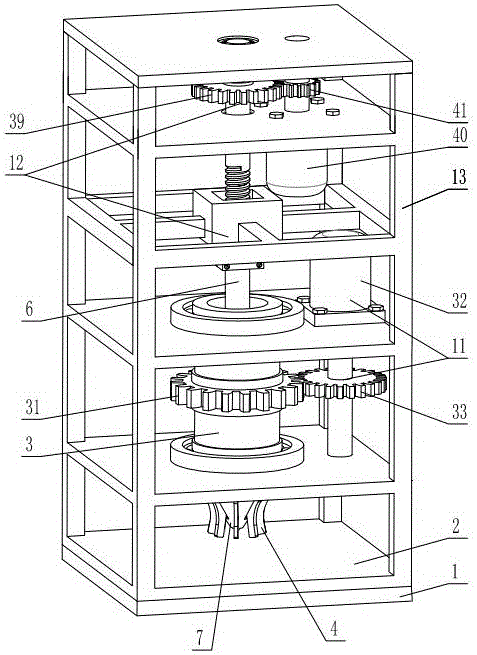

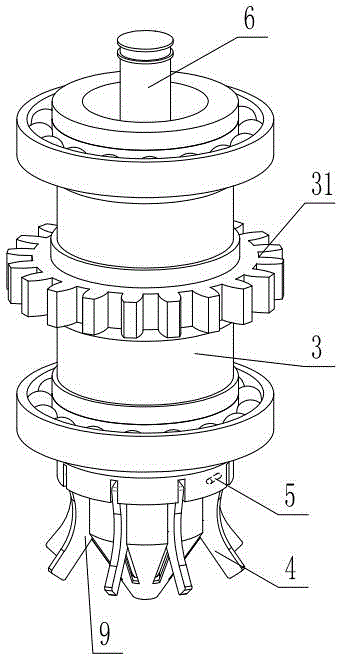

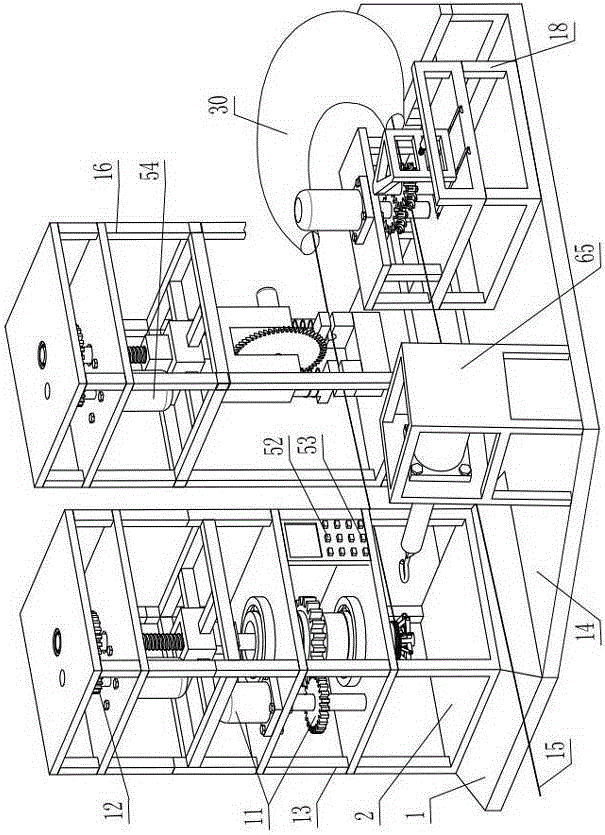

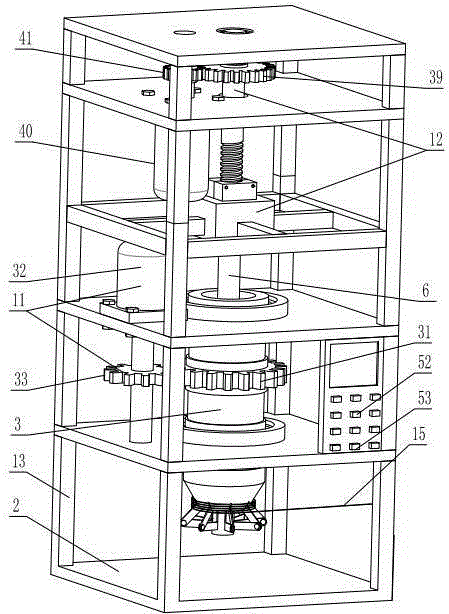

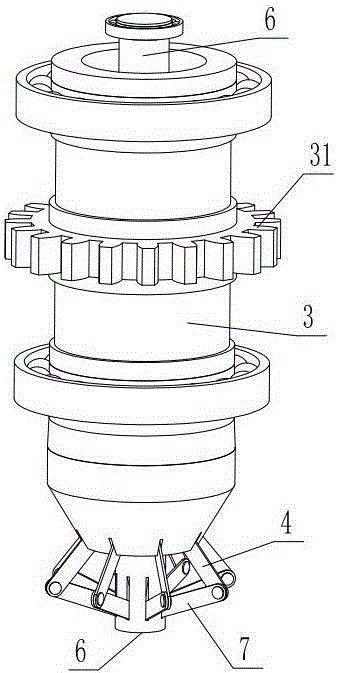

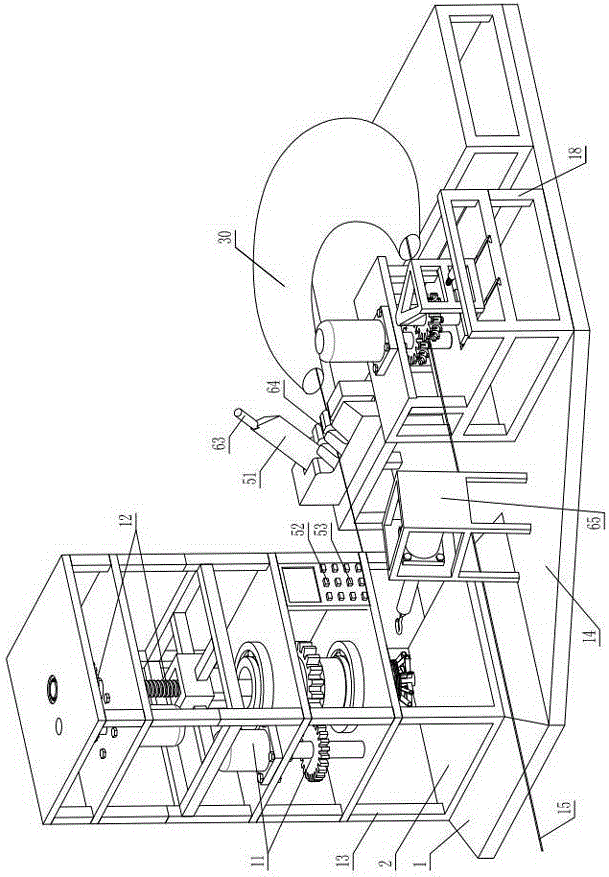

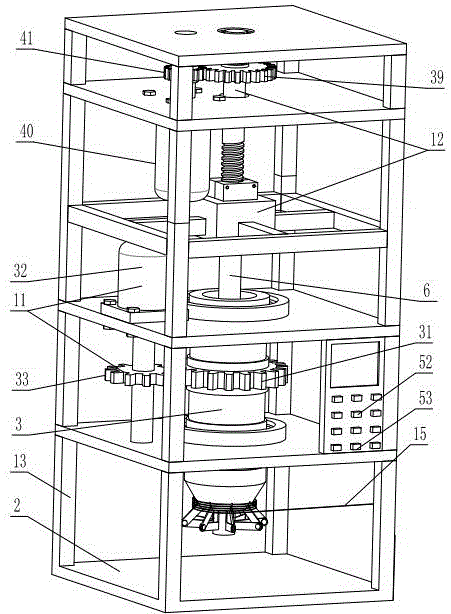

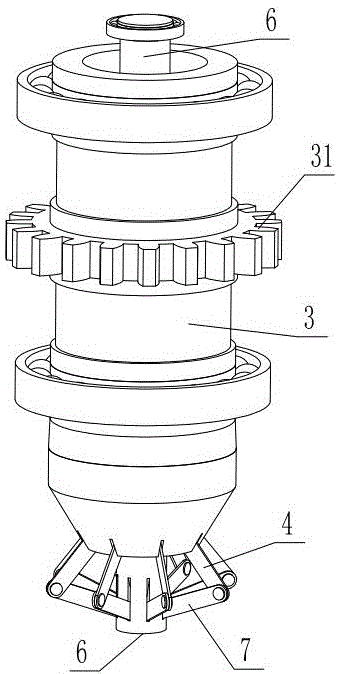

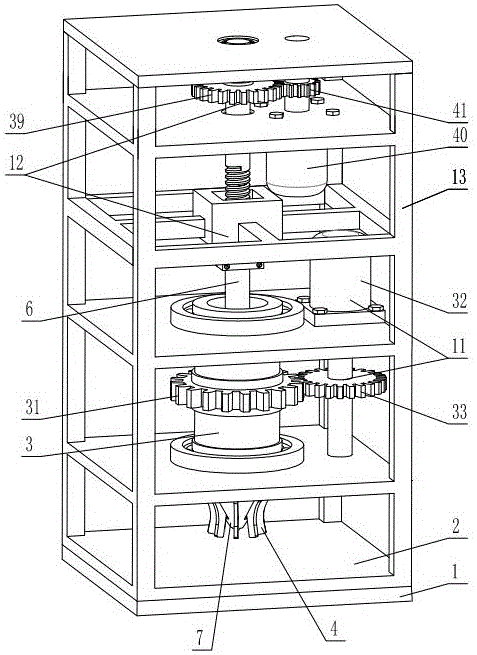

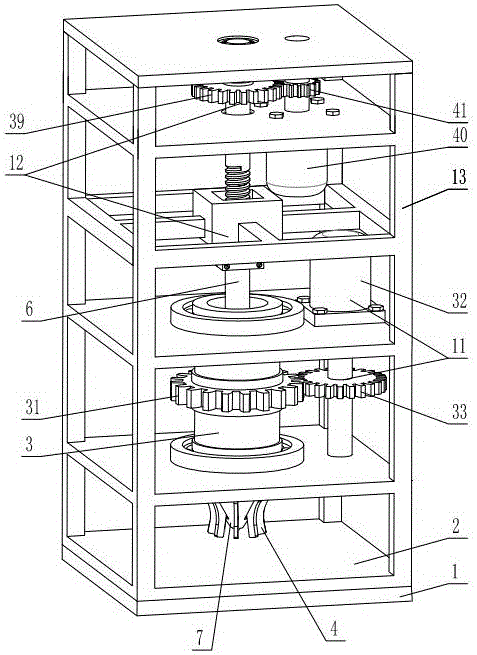

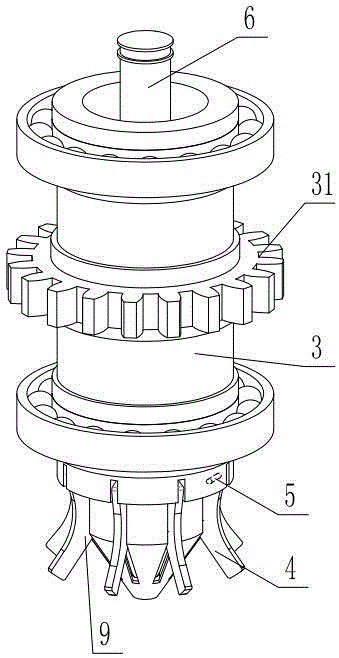

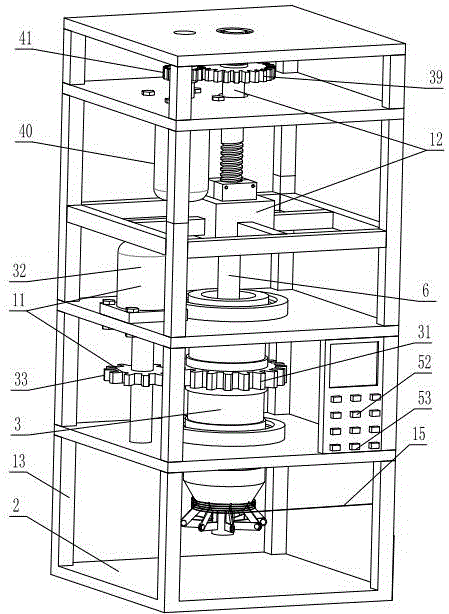

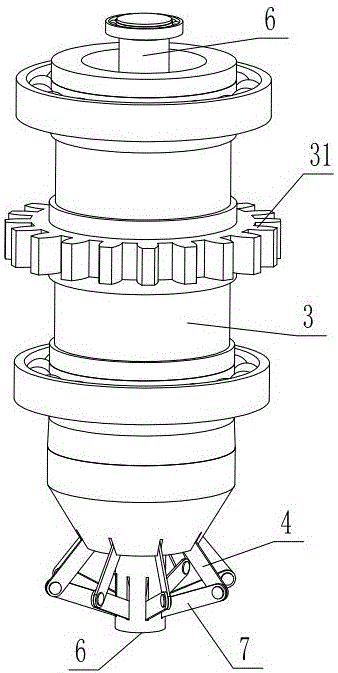

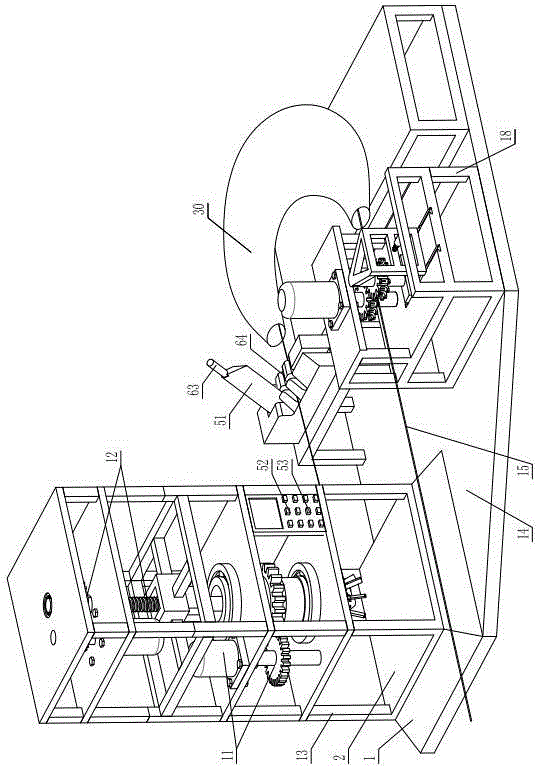

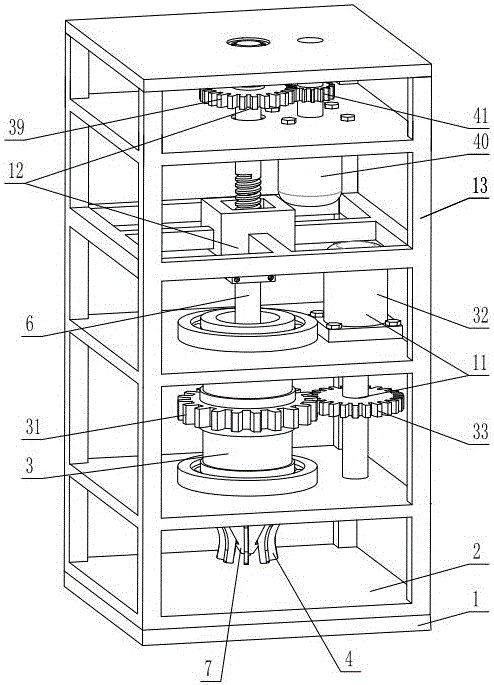

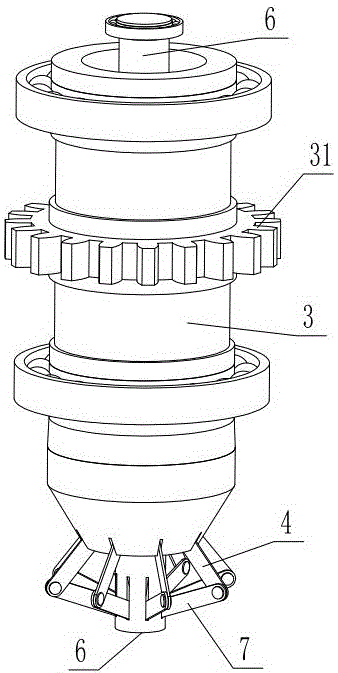

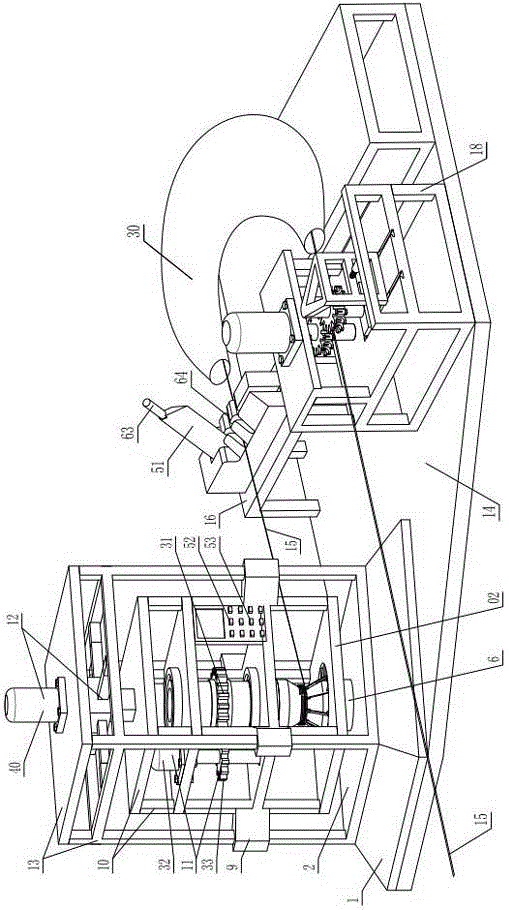

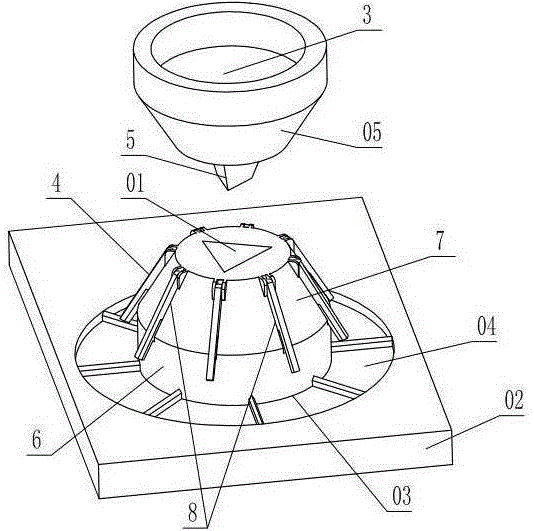

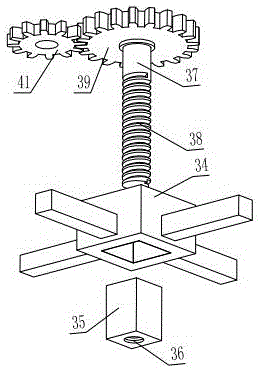

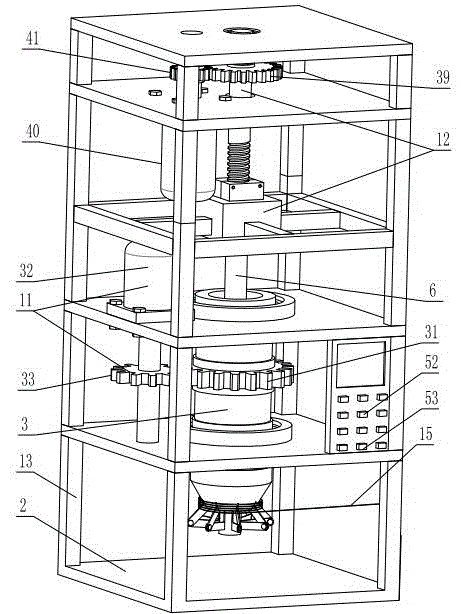

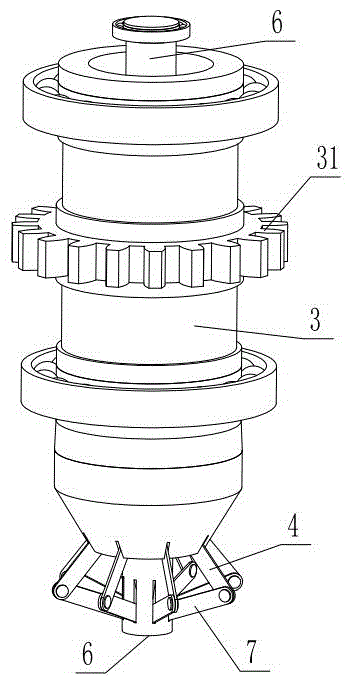

The invention discloses a power cable take-up device which comprises a base fixedly provided with a weighing machine. A main frame is installed on a weighing table of the weighing machine. A rotating sleeve is rotationally installed on the main frame. Hinged swing arms are evenly and annularly arranged at the lower portion of the rotating sleeve. The middles of the swing arms are bent to the center of the rotating sleeve. A center shaft is inserted in the axial direction inside the rotating sleeve in a sliding and plugging mode. A conical block with the downward tip end is fixedly arranged at the lower end of the center shaft. Tracks corresponding to the swing arms are evenly distributed on the conical face of the conical block. An extending block extending towards the tracks is fixedly arranged in the middle of each swing arm. A matching piece which can only move along the tracks is installed at the end of each extending block. The main frame is provided with a main power device and a lifting device. A cutting device is further installed on the base. The power cable take-up device further comprises a starting and stopping device which controls the main power device and the lifting device to be started and stopped. Waste cables can be automatically bundled and wound, bundling is compact and easy, automatic and accurate weighing is performed, automatic material throwing is performed, the automatic degree is high, the power cable take-up device can be operated by one person, and operation is easy.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

Power cable take-up equipment

The invention discloses power cable take-up equipment. The power cable take-up equipment comprises a base on which a weighing machine is fixedly arranged, wherein a main frame is mounted on a weighing platform of the weighing machine; a rotary sleeve is rotationally mounted on the main frame; articulated swing arms are uniformly arranged at the lower part of the rotary sleeve in a circling manner; the middles of the swing arms are bent toward the center of the rotary sleeve; a central shaft is inserted into the rotary sleeve in a sliding manner in the axial direction; a conical block of which the pointed end faces downwards is fixedly arranged at the lower end of the central shaft; tracks corresponding to the swing arms are uniformly distributed on the conical surface of the conical block; an extension block extending toward the tracks is fixedly arranged in the middle of each swing arm; a matching part which can only move along the corresponding track is mounted at the end part of each extension block; a main power device and a lifting device are mounted on the main frame; a cutting device is further mounted on the base; and the power cable take-up equipment also comprises a start and stop device which controls the main power device and the lifting device to start and stop. The power cable take-up equipment can automatically wind up waste cables in bundles, is secure in bundling, easy to bundle, automatic and accurate in weighing, automatic in material throwing and high in degree of automation, and can be simply operated by only one person.

Owner:董高正

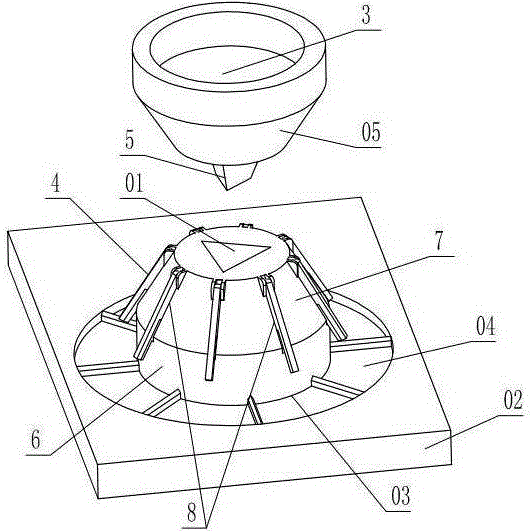

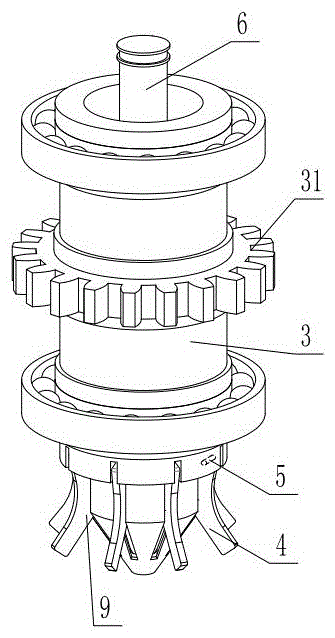

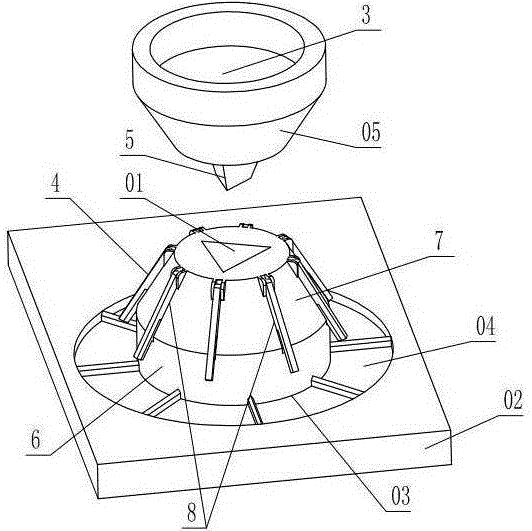

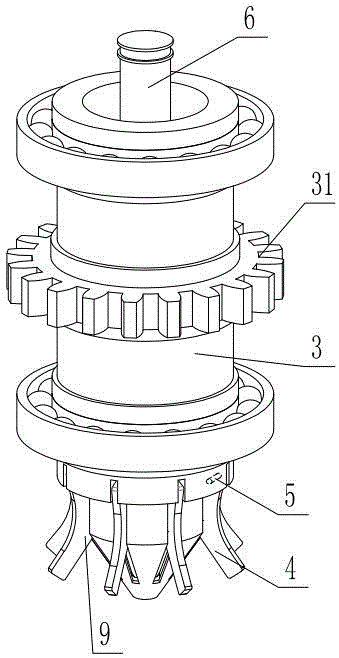

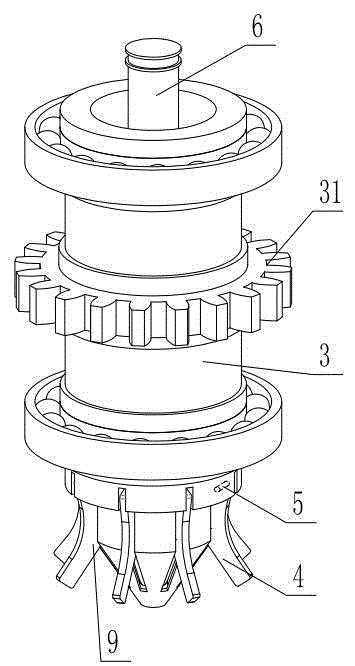

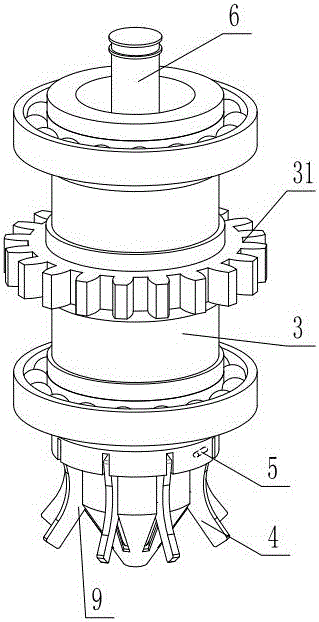

Waste and old cable winding device

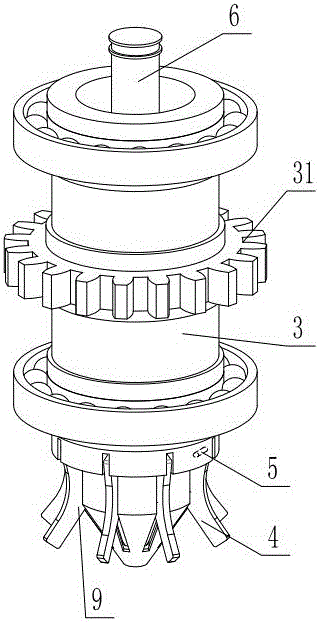

InactiveCN106429643AReasonable structureBundled tightlyFilament handlingBundling machine detailsStops deviceEngineering

The invention discloses a waste and old cable winding device. The waste and old cable winding device includes a base; a weighing apparatus is fixed on the base; a main frame is arranged on a weighing table of the weighing apparatus; a rotation sleeve is rotatably arranged on the main frame; an outer wall of the rotation sleeve is a cone-shaped structure having a thin lower end and a thick upper end; swinging arms are evenly arranged around the lower part of the rotation sleeve, and the swinging are hinged through horizontal hinge shafts; a central shaft is axially and slidingly inserted into the rotation sleeve; support arms are arranged around the lower end of the central shaft; the lower ends of the support arms are hinged to the central shaft, and the upper ends of the support arms are hinged to the lower ends of the corresponding swinging arms; when the central shaft slide upward to an upper stroke point, the support arms are perpendicular to the central shaft, and the lower ends of the swinging arms are further away from the central shaft than the upper ends of the swinging arms; when the central shaft slides downward to a lower stroke point, the upper ends of the swinging arms are further away from the central shaft than the two ends of the support arms, and the lower ends of the swinging arms are positioned outside connection lines between the upper ends of the swinging arms and the lower ends of the support arms; and the waste and old cable winding device also includes a main power device, a lifting device, a cutting device and a starting and stopping device. The waste and old cable winding device can automatically winding waste and old cables into bundles, is tight in bundle, can easily bind the cables, can automatically and accurately weigh the cables, can automatically throwing materials, is high in automatic level, can be operated by one man, and is simple to operate.

Owner:董高正

Distribution cable recovery device

The invention discloses a distribution cable recovery device which comprises a base which is fixedly provided with a weighing instrument, a main power device, a lifting device, a cutting device and a starting and stopping device; a main frame is installed on a weighing table of the weighing instrument and is rotationally provided with a rotary sleeve; the outer wall of the rotary sleeve is in a conical shape with thinner lower end and thicker upper end; swing arms which are hinged to the lower part of the rotary sleeve through horizontal hinge shafts respectively are uniformly arranged at the lower part of the rotary sleeve annularly; a center shaft is axially inserted into the rotary sleeve in a sliding manner; supporting arms are annularly arranged at the lower part of the center shaft; the lower end of each supporting arm is hinged to the center shaft; the upper end of each supporting arm is hinged to the lower end of the corresponding swing arm; when the center shaft slides upward to an up stroke point, the supporting arms are perpendicular to the center shaft, and the lower end of each swing arm is farther away from the center shaft than the upper end of each swing arm; and when the center shaft slides downward to a down stroke point, the upper end of each swing arm is farther away from the center shaft than the two ends of the corresponding supporting arm both, and the lower end of each swing arm is arranged on the outer side of a connecting line of the upper end of each swing arm and the lower end of the corresponding supporting arm. The power distribution cable collecting device can automatically enable a waste cable to be wound in bundles and is compact in bundle, liable in bundling up, high in automation degree with automatic accurate weighing and automatic material throwing and simple in operation with capability of operation by one person.

Owner:董高正

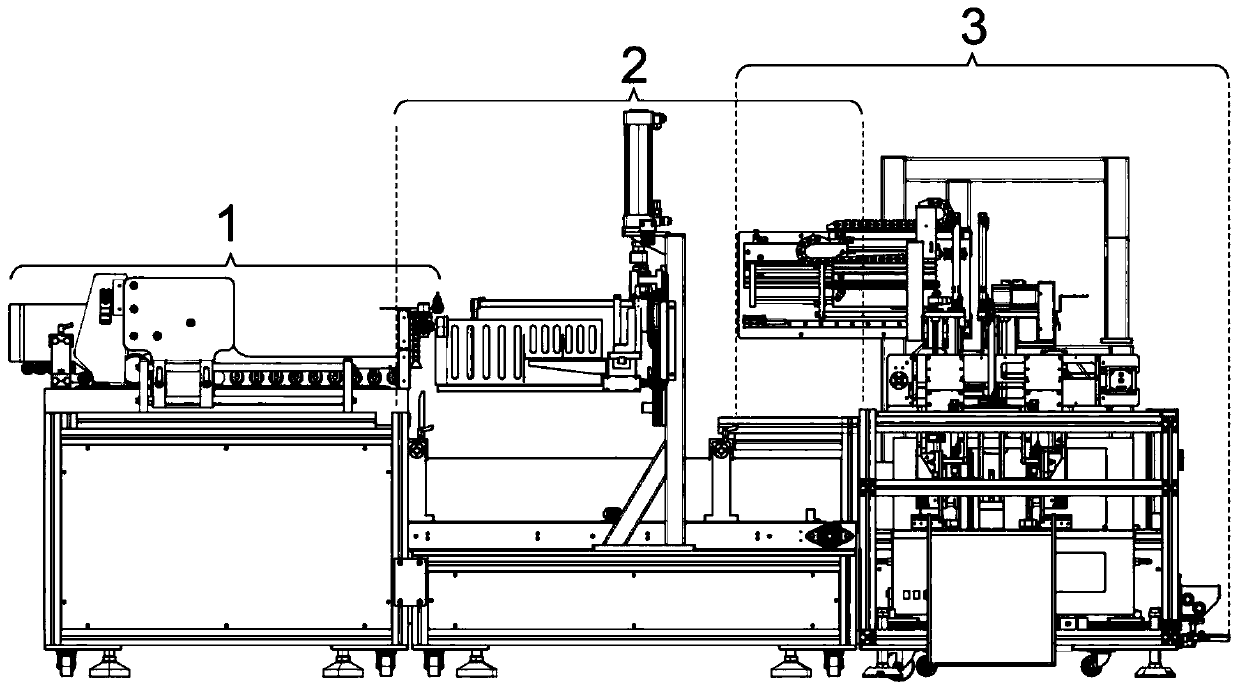

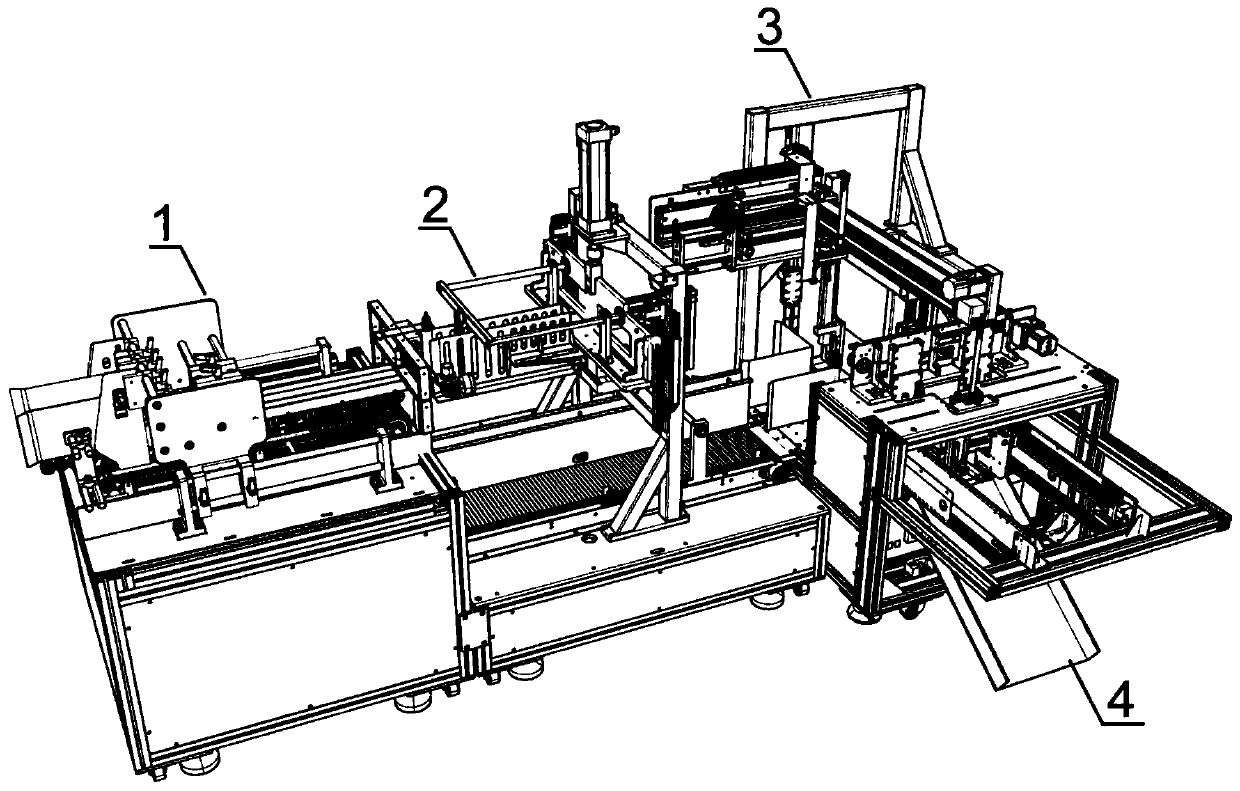

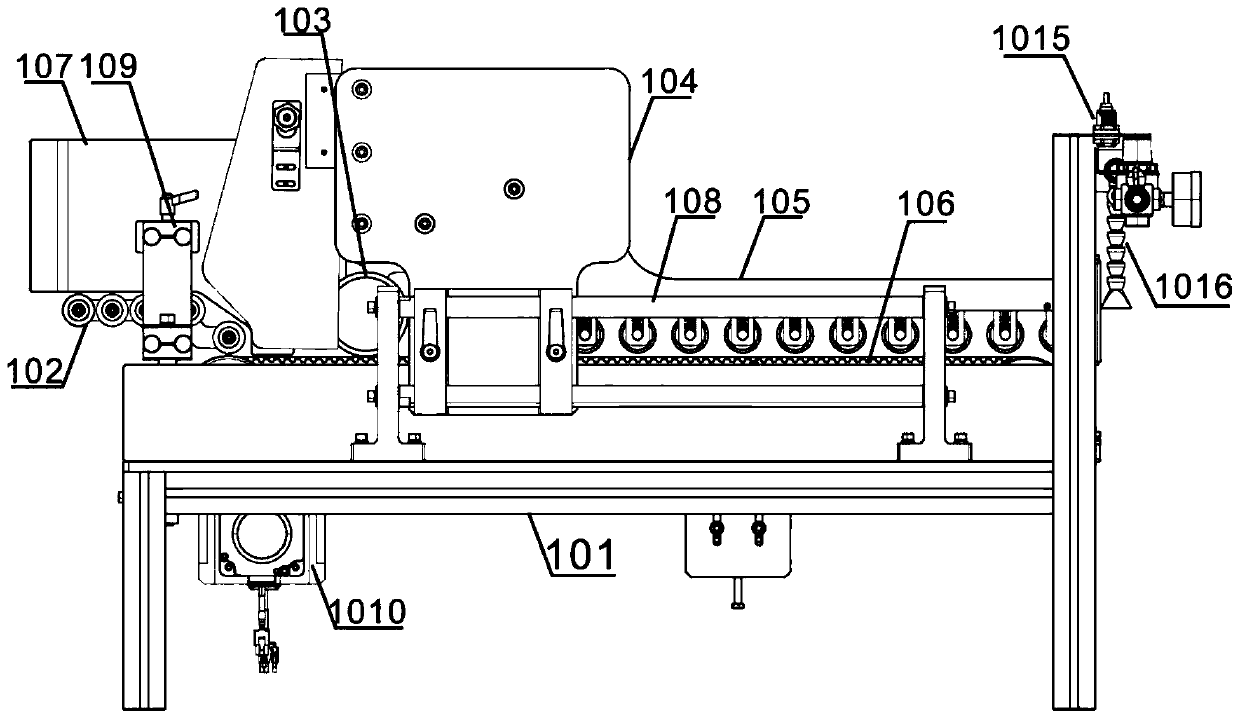

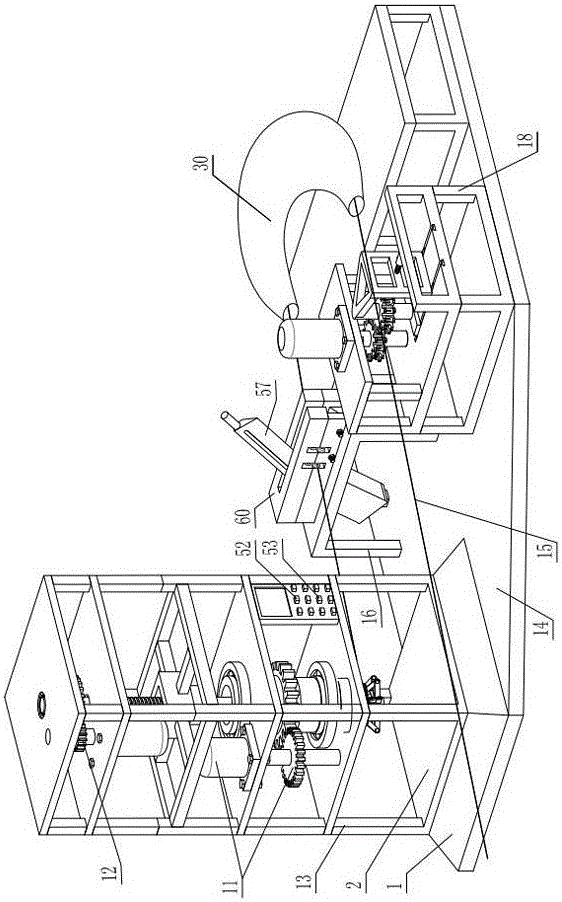

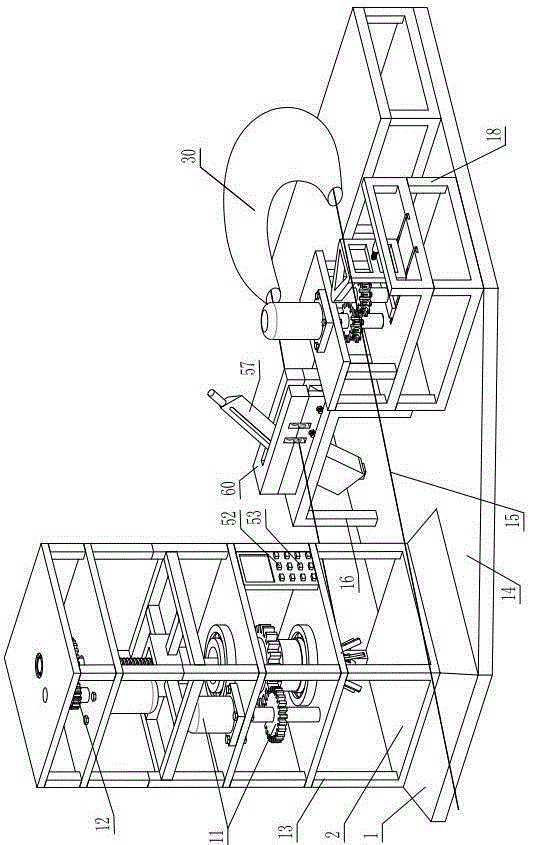

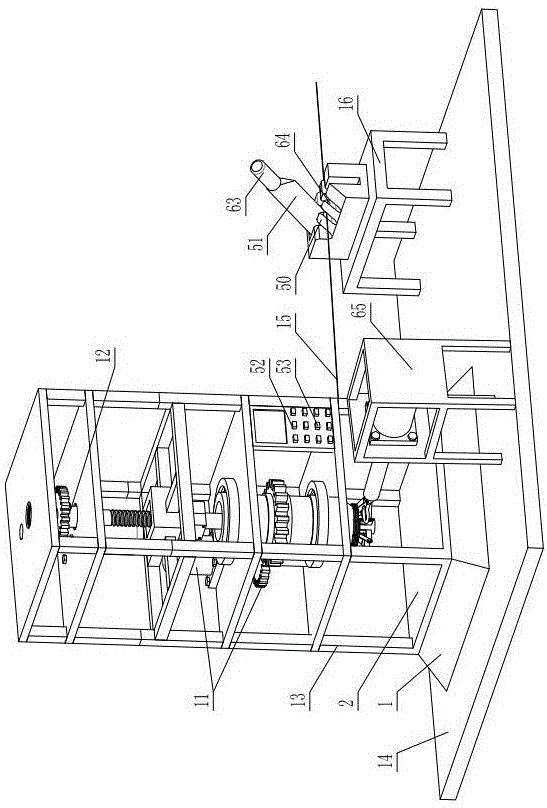

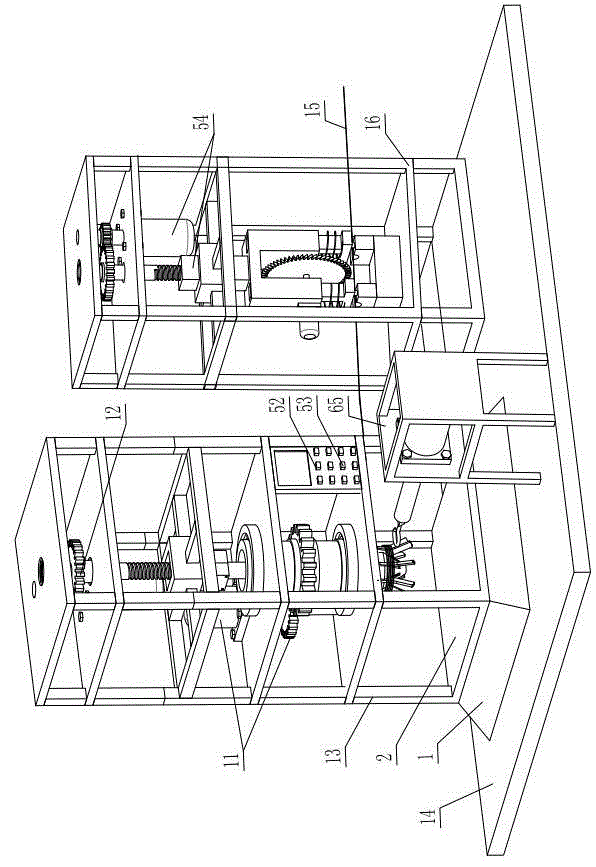

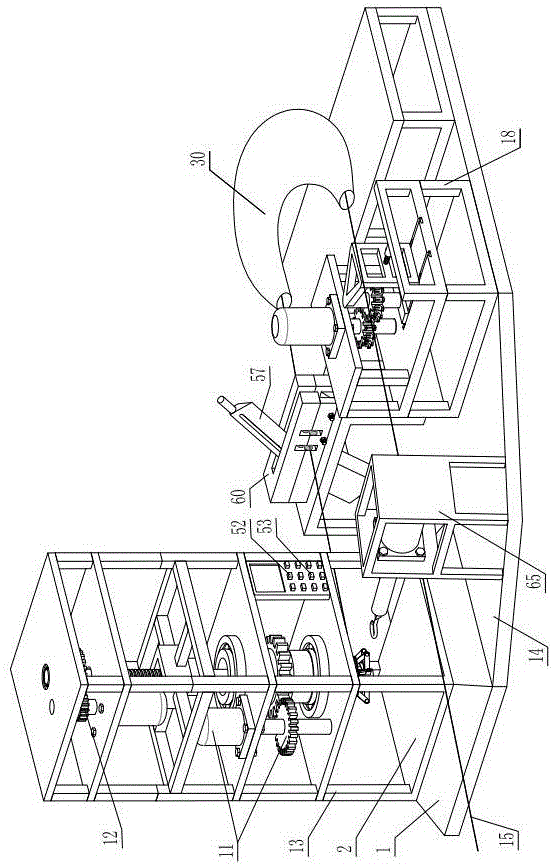

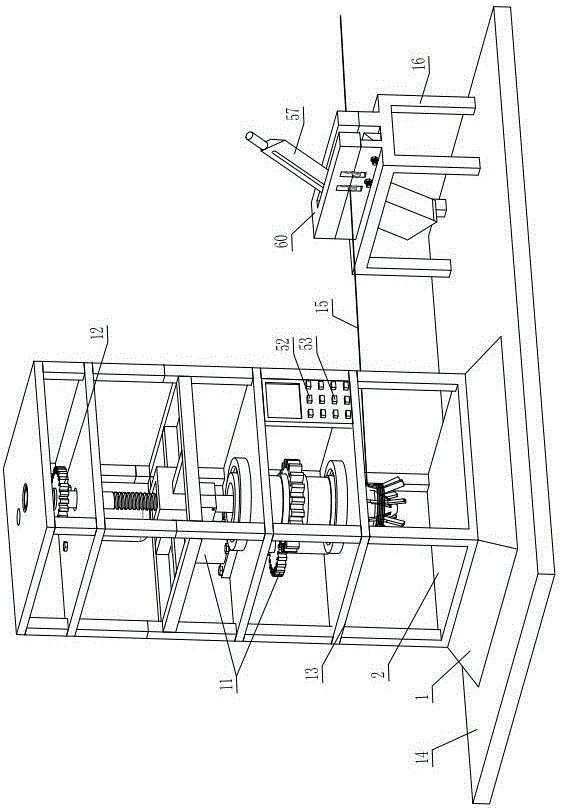

Automated bundling device used for packaging boxes

ActiveCN111498169ABundled tightlyNot easy to scatterPaper article packagingPackaging automatic controlConveyor beltIndustrial engineering

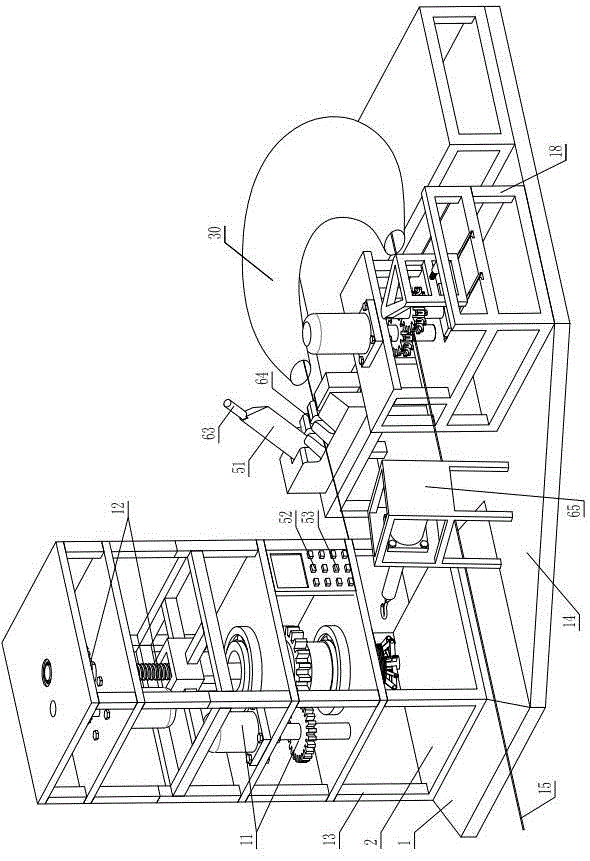

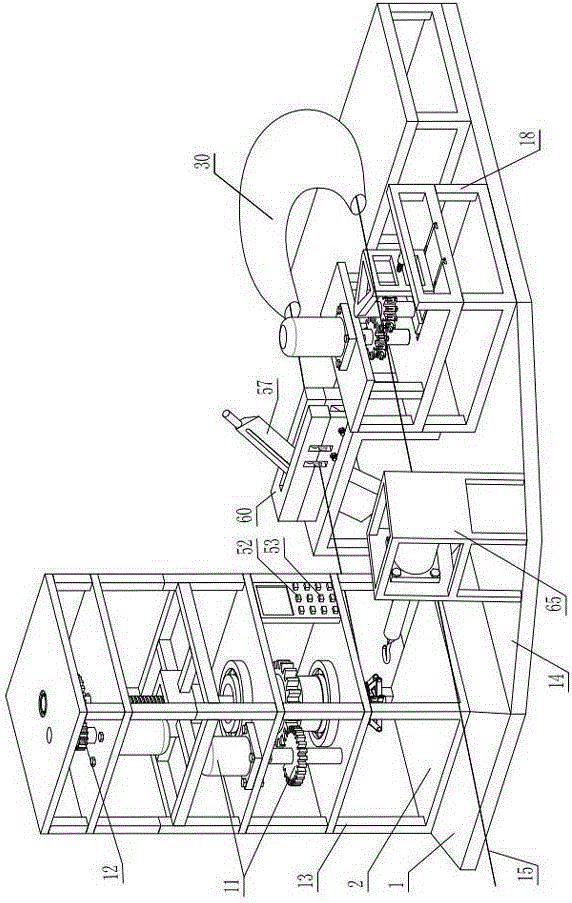

The invention belongs to the field of package production devices, and specifically provides an automated bundling device used for packaging boxes. The automated bundling device sequentially comprisesa counting and conveying part, a slow descending and conveying part and a bundling part. The counting and conveying part comprises a managing part and a conveying part. The slow descending and conveying part comprises a machine frame II, a conveying device and a receiving device located above the conveying device. The bundling part comprises a machine frame III, a pre-bundling push part located onthe machine frame III and a bundling machine. In the automated bundling device, the managing part is used for stacking a whole pile of packaging boxes, the packaging boxes move forwards under the effect of friction force and completely slide onto a conveyor belt device till falling from a conveyor belt, and the whole pile of packaging boxes can be conveyed out regularly in this manner. The receiving device is used for receiving the packaging boxes ejected out from the managing part and releasing the packaging boxes onto the conveying device, the pile of packaging boxes pass the bundling machine under the effect of a push device, the whole bundle of packaging boxes which are completely bundled are moved away through a discharging clamping mechanism, and therefore the counting and bundlingwork of the packaging boxes is completed.

Owner:浙江环力智能科技股份有限公司

Wind-up device of power cable

InactiveCN106710743AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingPower cableStart stop

The invention discloses a wind-up device of a power cable. The wind-up device comprises a pedestal with a weighing apparatus arranged fixedly; a main frame is installed at a weighing platform of the weighing apparatus; a rotating sleeve is installed at the main frame in a rotating manner; and oscillating arms are hinged to the lower part of the rotating sleeve uniformly in an annular mode and the central parts of the oscillating arms bend toward the center of the rotating sleeve. A central shaft is plugged into the rotating sleeve axially in a sliding manner; a conical block with a downward pointed end is fixedly arranged at the lower end of the central shaft; tracks corresponding to the oscillating arms are distributed uniformly at the conical surface of the conical block; extension blocks extending to the tracks are fixedly arranged at the middle parts of the oscillating arms; and cooperative elements that only move along the tracks are installed at the end portions of the extension blocks. A main power unit and a lifting unit are installed at the main frame. Besides, a cutting device is installed at the pedestal. In addition, the wind-up device also includes a starting-stopping device for controlling starting and stopping of the main power unit and the lifting unit. Therefore, wasted cables can be bundled and wound automatically, tightly, and easily; weighing can be carried out automatically and accurately; material flinging can be realized automatically; the automation degree is high; and the operation can be executed simply only by one person.

Owner:董高正

Power distribution cable winding equipment

InactiveCN106356151AReasonable structureBundled tightlyFilament handlingBasic electric elementsStops deviceConductor Coil

The invention discloses power distribution cable winding equipment. The power distribution cable winding equipment comprises a base and a starting and stopping device for controlling a main power device and a lifting device to start and stop, wherein the base is fixedly provided with a weighing apparatus. A main frame is mounted on a weighing platform of the weighing apparatus, a rotational sleeve is rotationally mounted on the main frame, swing arms hinged to the rotational sleeve are arranged on the lower portion circumferentially evenly, the middle of each swing arm bends towards the center of the rotational sleeve, a center shaft is inserted into the rotational sleeve axially slidably, a conical block with the pointed end downward is fixedly arranged at the lower end of the center shaft, rails corresponding to the swing arms are evenly distributed on the conical surface of the conical block, extension blocks extending towards the rails are fixedly arranged in the middles of the swing arms, fitting pieces only capable of moving along the rails are mounted at the ends of the extension blocks, the main power device and the lifting device are mounted on the main frame, and a cutting device is also mounted on the base. The power distribution cable winding equipment has the advantages of capabilities of winding waste cables in bundles tightly and being operated simply only by one person, easiness in bundling and high automation with automatic precise weighing and automatic material throwing functions.

Owner:董高正

Wind-up device of power cable

InactiveCN106710748AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingPower cableEngineering

The invention discloses a wind-up device of a power cable. The wind-up device comprises a pedestal with a weighing apparatus arranged fixedly; and a main frame is installed at a weighing platform of the weighing apparatus. A rotating sleeve is installed at the main frame in a rotating manner and the outer wall of the rotating sleeve is in a conical shape with a thin lower end and a thick upper end; and oscillating arms are hinged to the lower part of the rotating sleeve uniformly in an annular mode. A central shaft is plugged into the rotating sleeve axially in a sliding manner; support arms are arranged at the lower end of the central shaft in an annular manner; and the lower ends of the support arms are hinged to the central shaft and the upper ends of the support arms are hinged to the lower ends of the corresponding oscillating arms. When the central shaft slides upwardly to an upper travel point, the support arms are perpendicular to the central shaft and the upper ends of the oscillating arms are closer to the central shaft than the lower ends of the oscillating arms; and when the central shaft slides downwardly to a lower travel point, the two ends of the support arms are closer to the central shaft than the upper ends of the oscillating arms and the lower ends of the oscillating arms are located at the outer sides of connecting lines between the upper ends of the oscillating arms and the lower ends of the support arms. In addition, the wind-up device also consists of a main force device, a lifting device, a cutting device, and a starting and stopping device. Therefore, wasted cables can be bundled and wound automatically, tightly, and easily; weighing can be carried out automatically and accurately; material flinging can be realized automatically; the automation degree is high; and the operation can be executed simply only by one person. Moreover, the wind-up device can be operated simply.

Owner:董高正

Power distribution cable retrieving device

InactiveCN106710744AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingStops deviceConical surface

The invention discloses a power distribution cable retrieving device. The device comprises a pedestal which is fixedly provided with a weighing apparatus, a main frame is mounted on a weighing platform of the weighing apparatus, a rotation sleeve is mounted on the main frame rotationally, swing arms are arranged in the lower portion of the rotation sleeve uniformly and annularly, the middle portions of the swing arms bend towards the center of the rotation sleeve, a central shaft is inserted in a sliding manner in the axial direction in the rotation sleeve, a conical block whose tip is downward is fixedly arranged in the lower end of the central shaft, tracks corresponding to the swing arms are distributed in the conical surface of the conical block uniformly, the middle portions of the swing arms are fixedly provided with extension blocks which can extend towards the tracks, the end portions of the extension blocks are provided with cooperation pieces which can only move along the tracks, a main power device and an elevator are mounted on the main frame, the pedestal is provided with a cutter, and a start / stop device which controls start and stop of the main power device and the elevator is also included. According to the power distribution cable retrieving device, waste and old cables can be bundled and wound automatically, bundles are right, binding is easy, weighing is automatic and accurate, material throwing is automatic, the automatic degree is high, operations can be completed by one person, and operations are simple.

Owner:董高正

Distribution cable collecting device

InactiveCN106364981AReasonable structureBundled tightlyFilament handlingPackagingEngineeringStops device

The invention discloses a distribution cable collecting device which comprises a base which is fixedly provided with a weighing instrument, a main power device, a lifting device, a cutting device and a starting and stopping device; a main frame is installed on a weighing table of the weighing instrument and is rotationally provided with a rotary sleeve; the outer wall of the rotary sleeve is in a conical shape with thinner lower end and thicker upper end; swing arms which are hinged to the lower part of the rotary sleeve through horizontal hinge shafts respectively are uniformly arranged at the lower part of the rotary sleeve annularly; a center shaft is axially inserted into the rotary sleeve in a sliding manner; supporting arms are annularly arranged at the lower part of the center shaft; the lower end of each supporting arm is hinged to the center shaft; the upper end of each supporting arm is hinged to the lower end of the corresponding swing arm; when the center shaft slides upward to an up stroke point, the supporting arms are perpendicular to the center shaft, and the lower end of each swing arm is farther away from the center shaft than the upper end of each swing arm; and when the center shaft slides downward to a down stroke point, the upper end of each swing arm is farther away from the center shaft than the two ends of the corresponding supporting arm both, and the lower end of each swing arm is arranged on the outer side of a connecting line of the upper end of each swing arm and the lower end of the corresponding supporting arm. The distribution cable collecting device can automatically enable a waste cable to be wound in bundles and is compact in bundle, liable in bundling up, high in automation degree with automatic accurate weighing and automatic material throwing and simple in operation with capability of operation by one person.

Owner:董高正

Distribution cable recovery apparatus

InactiveCN106158157AReasonable structureBundled tightlyFilament handlingBasic electric elementsStart stopEngineering

The invention discloses a distribution cable recovery apparatus. The distribution cable recovery apparatus comprises a base, wherein a weighing apparatus is fixedly arranged on the base; a main frame is mounted on a weighing platform of the weighing apparatus; a rotary sleeve is rotationally mounted on the main frame; hinged swing arms are uniformly and annularly arranged at the lower part of the rotary sleeve; the middle parts of the swing arms are bent towards the center of the rotary sleeve; a center shaft is inserted in the rotary shaft in an axial direction glidingly; a conical block with a downward sharp end is fixedly arranged at the lower end of the center shaft; tracks corresponding to the swing arms are uniformly formed in the conical surface of the conical block; extension blocks which extend to the tracks are fixedly arranged on the middle parts of the swing arms; matching parts which can only move along the tracks are mounted on the end parts of the extension blocks; the main frame is provided with a main power apparatus and a lifting apparatus; the base is also provided with a cutting apparatus; and the distribution cable recovery apparatus also comprises a starting-stopping apparatus which is used for controlling the starting and stopping of the main power apparatus and the lifting apparatus. By adoption of the distribution cable recovery apparatus, waste cables can be wound in bunches automatically and tightly; the cables can be bundled up easily; the cables can be weighted automatically and precisely; automatic material throwing can be carried out; and therefore, the distribution cable recovery apparatus is high in automatic degree, simple to operate and can be operated by one person.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

Power distribution cable take-up device

InactiveCN106158158AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingStart stopCircular cone

The invention discloses a power distribution cable take-up device which comprises a base fixedly provided with a weighing machine. A main frame is mounted on a weighing platform of the weighing machine, a rotary sleeve is rotatably mounted on the main frame, a hinged swing arm is evenly annularly arranged on the lower portion of the rotary sleeve, the middle portion of the swing arm bends to the center of the rotary sleeve, a central shaft is axially slidably inserted in the rotary sleeve, a cone block with the tip extending downwards is fixedly arranged at the lower end of the central shaft, a track corresponding to the swing arm is evenly distributed on the cone surface of the cone block, an extending block extending to the track is fixedly arranged in the middle of the swing arm, a fitting piece only capable of moving along the track is mounted at the end portion of the extending block, a main power device and a lifting device are mounted on the main frame, a cutting device is further mounted on the base, and the power distribution cable take-up device further comprises a start-stop device controlling the main power device and the lifting device. By the arrangement, waste cables can be automatically wound in bundles, and the power distribution cable take-up device is compact in bundle, easy to bundle up, automatically accurate in weighing, automatic in material throwing, high in automation level, capable of being operated by one person and simple in operation.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

Recovery equipment for electric power distribution cables

InactiveCN106364978AReasonable structureBundled tightlyFilament handlingPackagingElectric power distributionEngineering

The invention discloses recovery equipment for electric power distribution cables. The recovery equipment comprises a base, and a weighing device is fixedly arranged on the base. A main frame is mounted on a weighing table of the weighing device. A rotating sleeve is rotatably mounted on the main frame. Swing arms are evenly and circumferentially arranged on the lower portion of the rotating sleeve in a hinged mode. The middle portions of the swing arms are bent towards the center of the rotating sleeve. A center shaft is slidably inserted into the rotating sleeve in the axial direction. A conical block with the pointed end facing downwards is fixedly arranged at the lower end of the center shaft. Tracks which correspond to the swing arms are evenly distributed on the conical surface of the conical block. Extension blocks which extend towards the tracks are fixedly arranged on the middle portions of the swing arms. Mating parts which can only move along the tracks are mounted at the ends of the extension blocks. A main power device and a lifting device are mounted on the main frame. A cutting device is further mounted on the base. The recovery equipment further comprises a starting and stopping device used for controlling the main power device and the lifting device to start and stop. According to the recovery equipment for electric power distribution cables, a bundle of waste cables can be automatically wound, bundles are firmly bound, binding is easy, automatic and accurate weighing is achieved, and materials are thrown automatically; and the automation degree is high, the recovery equipment can be operated by one person, and operation is easy.

Owner:董高正

Waste cable collecting device

InactiveCN106364748AReasonable structureBundled tightlyApparatus for cutting/splicing cablesPackagingEngineeringStops device

The invention discloses a waste cable collecting device which comprises a base which is fixedly provided with a weighing instrument, a main power device, a lifting device, a cutting device and a starting and stopping device; a main frame is installed on a weighing table of the weighing instrument and is rotationally provided with a rotary sleeve; the outer wall of the rotary sleeve is in a conical shape with thinner lower end and thicker upper end; swing arms which are hinged to the lower part of the rotary sleeve through horizontal hinge shafts respectively are uniformly arranged at the lower part of the rotary sleeve annularly; a center shaft is axially inserted into the rotary sleeve in a sliding manner; supporting arms are annularly arranged at the lower part of the center shaft; the lower end of each supporting arm is hinged to the center shaft; the upper end of each supporting arm is hinged to the lower end of the corresponding swing arm; when the center shaft slides upward to an up stroke point, the supporting arms are perpendicular to the center shaft, and the lower end of each swing arm is farther away from the center shaft than the upper end of each swing arm; and when the center shaft slides downward to a down stroke point, the upper end of each swing arm is farther away from the center shaft than the two ends of the corresponding supporting arm both, and the lower end of each swing arm is arranged on the outer side of a connecting line of the upper end of each swing arm and the lower end of the corresponding supporting arm. The waste cable collecting device can automatically enable a waste cable to be wound in bundles and is compact in bundle, liable in bundling up, high in automation degree with automatic accurate weighing and automatic material throwing and simple in operation with capability of operation by one person.

Owner:董高正

Electric power distribution cable recycling device

InactiveCN106409440AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingElectric power distributionStops device

An electric power distribution cable recycling device disclosed by the present invention comprises a pedestal fixedly equipped with a weighing device, a main rack is arranged on a weighing table of the weighing device, and a rotating sleeve is arranged on the main rack rotatably. The outer wall of the rotating sleeve is a cone of which the lower end is thin and the upper end is thick, the lower part of the rotating sleeve is uniformly and annularly equipped with swing arms which are in hinge joint via horizontal hinge shafts, and a central shaft is inserted in the rotating sleeve slidably and axially. The lower end of the central shaft is annularly equipped with supporting arms, the lower ends of the supporting arms are in hinge joint with the central shaft, and the upper ends are in hinge joint with the lower ends of the corresponding swing arms. When the central shaft upwards slides to an upper stroke point, the supporting arms are vertical with the central shaft, and the distances between the lower ends of the swing arms and the central shaft are longer than the distance between the upper ends of the swing arms and the central shaft. When the central shaft downwards slides to a lower stroke point, the distances between the upper ends of the swing arms and the central shaft are longer than the distances between the two ends of the supporting arms and the central shaft, and the lower ends of the swing arms are located at the outer sides of the connection lines of the upper ends of the swing arms and the lower ends of the supporting arms. The electric power distribution cable recycling device also comprises a main power device, an elevating device, a cutting device and a starting-stopping device The electric power distribution cable recycling device can bundle and wind the waste cables automatically, can bundle firmly, weigh automatically and accurately and toss materials automatically, is easy to bundle and simple to operate, is high in automation degree, and can be operated by a single person.

Owner:董高正

Waste cable collector

InactiveCN106356158AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingStops deviceEngineering

The invention discloses a waste cable collector. The waste cable collector comprises a base and a starting and stopping device, wherein a weighing apparatus is fixedly arranged on the base; a main frame is mounted on a weighing table of the weighing apparatus; a rotating sleeve is rotatably mounted on the main frame; hinged swinging arms are uniformly arranged on the lower part of the rotating sleeve annularly; the middle of each swinging arm is bent towards the center of the rotating sleeve; a central shaft is slidably inserted in the rotating sleeve in the axial direction; a conical block of which the tip is downward is fixedly arranged at the lower end of the central shaft; tracks which correspond to the swinging arms are uniformly distributed on a conical surface of the conical block; an extending block which extends to the corresponding track is fixedly arranged in the middle of each swinging arm; a matched piece which only can move along the corresponding track is mounted at an end of each extending block; a main power device and a lifting device are mounted on the main frame; a cutting device is further mounted on the base; and the starting and stopping device controls starting and stopping of the main power device and the lifting device. Waste cables can be automatically wound into bundles, the bundles are compact, bundling is facilitated, automatic accurate weighing is realized, automatic throwing is also realized, degree of automation is high, a person can operate the waste cable collector, and the waste cable collector is simple to operate.

Owner:董高正

Take-up device for waste cables

InactiveCN106364992AReasonable structureBundled tightlyFilament handlingPackagingStops deviceElectric cables

The invention discloses a take-up device for waste cables. The take-up device comprises a base, and a weighing device is fixedly arranged on the base. A main frame is mounted on a weighing table of the weighing device. A rotating sleeve is rotatably mounted on the main frame. The outer wall of the rotating sleeve is in the shape of a cone with the lower end being thin and the upper end being thick. Swing arms are evenly and circumferentially arranged on the lower portion of the rotating sleeve in a hinged mode through horizontal hinge shafts. A center shaft is slidably inserted into the rotating sleeve in the axial direction. Supporting arms are circumferentially arranged at the lower end of the center shaft. The lower ends of the supporting arms are hinged to the center shaft. The upper ends of the supporting arms are hinged to the lower ends of the corresponding swing arms. When the center shaft slides upwards to an upper travel point, the supporting arms are perpendicular to the center shaft, and the lower ends of the swing arms are farther away from the center shaft compared with the upper ends of the swing arms; and when the center shaft slides downwards to a lower travel point, the upper ends of the swing arms are farther away from the center shaft compared with the two ends of each supporting arm, and the lower ends of the swing arms are located outside connecting lines of the upper ends of the swing arms and the lower ends of the supporting arms. The take-up device further comprises a main power device, a lifting device, a cutting device and a starting and stopping device. According to the take-up device for waste cables, a bundle of waste cables can be wound automatically, bundles are bound firmly, binding is easy, automatic and accurate weighing is achieved, and materials are thrown automatically; and the automation degree is high, the take-up device can be operated by one person, and operation is easy

Owner:董高正

Waste cable recycling device

InactiveCN106653235AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingConical formsStops device

The invention discloses a waste cable recycling device, including a base fixedly provided with a weighing instrument. A platform of the weighing instrument is equipped with a main frame thereon. The main frame is equipped rotatably with a rotary sleeve. The outer wall of the rotary sleeve is in a conic shape with a small lower end and a large upper end. The lower part of the sleeve is provided with a swing arm hinged through a horizontal hinge shaft uniformly in a manner of a ring. A central shaft is inserted axially in a slidable manner in the sleeve. The lower end of the central shaft is provided with a support arm in a manner of a ring. The lower end of the support arm is hinged to the central shaft. The upper end of the support arm is hinged to the lower end of the corresponding swing arm. When the central shaft slides upward to an up stroke point, the support arm and the central shaft are arranged vertically, and the lower end of the support arm is farther from the central shaft than the upper end is. When the central shaft slides downward to a down stroke point, the upper end of the swing arm is farther from the central shaft than the two ends of the support arm are, and the lower end of the swing arm is located at the outer side of a connecting line between the upper end of the swing arm and the lower end of the support arm. The waste cable recycling device also includes a main power device, a lifting device, a cutting device, and a start and stop device. The device can automatically bundle and wind waste cables, is tight in bundling, easy to bundle, automatic and accurate in weighing, automatic in material throwing and high in degree of automation, can be operated by one person and is simple in operation.

Owner:董高正

Power distribution cable recoverer

InactiveCN106356157AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingStops deviceConical surface

The invention discloses a power distribution cable recoverer. The power distribution cable recoverer comprises a base and a starting and stopping device for controlling a main power device and a lifting device to start and stop, wherein the base is fixedly provided with a weighing apparatus. A main frame is mounted on a weighing platform of the weighing apparatus, a rotational sleeve is rotationally mounted on the main frame, swing arms hinged to the rotational sleeve are arranged on the lower portion circumferentially evenly, the middle of each swing arm bends towards the center of the rotational sleeve, a center shaft is inserted into the rotational sleeve axially slidably, a conical block with the pointed end downward is fixedly arranged at the lower end of the center shaft, rails corresponding to the swing arms are evenly distributed on the conical surface of the conical block, extension blocks extending towards the rails are fixedly arranged in the middles of the swing arms, fitting pieces only capable of moving along the rails are mounted at the ends of the extension blocks, the main power device and the lifting device are mounted on the main frame, and a cutting device is also mounted on the base. The power distribution cable recoverer has the advantages of capabilities of winding waste cables in bundles tightly and being operated simply only by one person, easiness in bundling and high automation with automatic precise weighing and automatic material throwing functions.

Owner:董高正

Power distribution cable collector

InactiveCN106710750AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingPower cableEngineering

The invention discloses a power distribution cable collector which comprises a base fixedly provided with a weighing instrument. The weighing platform of the weighing instrument is equipped with a main frame which is rotatingly equipped with a rotation sleeve. The lower part of the rotation sleeve is uniformly provided with hinged swing arms in a ring. The central parts of the swing arms are bent to the center of the rotation sleeve. A center shaft is slidingly inserted into the rotation sleeve axially. The lower end of the center shaft is fixedly provided with a conical block with a downward tip. Rails corresponding to the swing arms are uniformly distributed at the conical surface of the conical block. The middle part of the swing arms are fixedly provided with extension blocks extending to the rails. The end parts of the extension blocks are equipped with mating members which can only move along the rails. The main frame is equipped with a main power device and a lifting device. The base is also equipped with a cutting device. The power cable recovery device also includes a start and stop device which controls the start and stop of the main power device and the lifting device. Waste cables can be automatically bundled and winded, a bundle is compact, the bundling is easy, automatic precise weighing and automatic throwing are achieved, the degree of automation is high, one man can operate the device, and the operation is simple.

Owner:董高正

Waste cable retrieving device

InactiveCN106710747AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingConical formsEngineering

The invention discloses a waste cable retrieving device. The device comprises a pedestal which is fixedly provided with a weighing apparatus, a main frame is mounted on a weighing platform of the weighing apparatus, a rotation sleeve is mounted on the main frame rotationally, the outer wall of the rotation sleeve is of a conical shape which is thin in the lower end and thick in the upper end, swing arms which are hinged via horizontal hinge axles are arranged in the lower portion of the rotation sleeve uniformly and annularly, a central shaft is inserted in a sliding manner in the axial direction in the rotation sleeve, support arms are arranged in the lower end of the central shaft annularly, the lower ends of the support arms are hinged to the central shaft, and the upper ends of the support arms are hinged to the lower ends of the corresponding swing arms; when the central shaft slides upwardly to an upper stroke point, the support arms are arranged vertical to the central shaft, and the lower ends of the swing arms are further from the central shaft than the upper ends of the same; when the central shaft slides downwardly to a lower stroke point, the upper ends of the swing arms are further from the central shaft than both the upper and lower ends of the support arms, and the lower ends of the swing arms are positioned outside connecting lines between the upper ends of the swing arms and the lower ends of the swing arms; and a main power device, an elevating device, a cutting device and a start / stop device are also included. According to the waste cable retrieving device, waste and old cables can be bundled and wound automatically, bundles are right, binding is easy, weighing is automatic and accurate, material throwing is automatic, the automatic degree is high, operations can be completed by one person, and operations are simple.

Owner:董高正

Electric power distribution cable winding machine

InactiveCN106115374AReasonable structureBundled tightlyFilament handlingWinding machineElectric power distribution

The invention discloses an electric power distribution cable winding machine. The machine comprises a base fixed with a weighing machine; a main frame is mounted on a weighing table of the weighing machine; a rotating cover is rotationally mounted on the main frame; hinged swing arms are uniformly encircled at the lower part of the rotating cover; the middle parts of the swing arms are bent to the center of the rotating cover; a center shaft is axially slidingly inserted in the rotating cover; a conical block with a downward tip is fixed at the lower end of the center shaft; rails corresponding to the swing arms are uniformly distributed on the conical surface of the conical block; extension blocks extending to the rails are fixed at the middle parts of the swing arms; matching pieces capable of moving along the rails are mounted at the end parts of the extension blocks; a main power device and a lifting device are mounted on the main frame; and a cutting device is mounted on the base. The machine further comprises a start / stop device for controlling start and stop of the main power device and the lifting device. The machine can automatically wind waste cables as bundles, tight bundling is realized, and the machine is easy to bind, is automatic and precise in weighing, is automatic in polishing, is high in automation degree, can operate by one person, and is simple in operation.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

Power cable recovery device

InactiveCN106710751AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingStops deviceEngineering

The invention discloses a power cable recovery device which comprises a base fixedly provided with a weighing instrument. The weighing platform of the weighing instrument is equipped with a main frame which is rotatingly equipped with a rotation sleeve. The lower part of the rotation sleeve is uniformly provided with hinged swing arms in a ring. The central parts of the swing arms are bent to the center of the rotation sleeve. A center shaft is slidingly inserted into the rotation sleeve axially. The lower end of the center shaft is fixedly provided with a conical block with a downward tip. Rails corresponding to the swing arms are uniformly distributed at the conical surface of the conical block. The middle part of the swing arms are fixedly provided with extension blocks extending to the rails. The end parts of the extension blocks are equipped with mating members which can only move along the rails. The main frame is equipped with a main power device and a lifting device. The base is also equipped with a cutting device. The power cable recovery device also includes a start and stop device which controls the start and stop of the main power device and the lifting device. Waste cables can be automatically bundled and winded, a bundle is compact, the bundling is easy, automatic precise weighing and automatic throwing are achieved, the degree of automation is high, one man can operate the device, and the operation is simple.

Owner:董高正

Waste cable recoverer

InactiveCN106364751AReasonable structureBundled tightlyApparatus for cutting/splicing cablesPackagingStops deviceConical surface

The invention discloses a waste cable recoverer. The waste cable recoverer comprises a base. A weighter is fixedly arranged on the base. A main frame is mounted on a weighing table of the weighter. A rotating sleeve is rotatably mounted on the main frame. Hinged swing arms are evenly and circumferentially arranged on the lower portion of the rotating sleeve. The middle portions of the swing arms bend towards to the center of the rotating sleeve. A center shaft is axially inserted into the rotating sleeve in a sliding mode. A conical block with the pointed end facing downwards is fixedly arranged at the lower end of the center shaft. Tracks corresponding to the swing arms are evenly distributed on a conical surface of the conical block. Extension blocks extending to the tracks are fixedly arranged in the middle portions of the swing arms. Matched parts which only can move along the tracks are mounted at the ends of the extension blocks. A main power device and a lifting device are mounted on the main frame. A cutting device is further mounted on the base. The distributing cable recoverer further comprises a start and stop device used for controlling the main power device and the lifting device to start and stop. By adoption of the waste cable recoverer, a bundle of waste cables can be wound automatically, the bundle is firm, binding is easy, weighing is automatic and accurate, materials are thrown automatically, the automation degree is high, and operation is conducted by only one person easily.

Owner:董高正

Waste cable recovery device

InactiveCN106698109AReasonable structureBundled tightlyFilament handlingPackagingStart stopEngineering

The invention discloses a waste cable recovery device which comprises a base fixedly provided with a weighting machine; a main frame is arranged on a weighing platform of the weighting machine; a rotating sleeve is rotationally arranged on the main frame; the external wall of the rotating sleeve is in a lower-end-thin and upper-end-thick conical shape; swinging arms hinged through horizontal hinged shafts are uniformly arranged at the lower part of the rotating sleeve in an annular manner; a center shaft is arranged in the rotating sleeve in an axial sliding inserting manner; supporting arms are arranged at the lower end of the center shaft in an annular manner; the lower ends of the supporting arms are hinged to the center shaft; the upper ends of the supporting arm are hinged to the lower ends of the swinging arms correspondingly; when the center shaft slides to an upstroke point upwards, the supporting arms are perpendicular to the center shaft, and the distance between the lower end of each swinging arm and the center shaft is greater than the distance between the upper end of each swinging arm and the center shaft; and when the center shaft slides to a downstroke point downwards, the distance between the upper end of each swinging arm and the center shaft is greater than the distance between the two ends of each supporting arm and the center shaft, and the lower ends of the swinging arms are located on the outer sides of connecting lines of the upper ends of the swinging arms and the lower ends of the supporting arms. The waste cable recovery device further comprises a main power device, a lifting device, a cutting device and a start-stop device. The waste cable recovery device can automatically wind wasted and used cables in bundles, the bundles are tight and compact, the bundling is easy, automatic precise weighing and automatic material throwing are realized, the automation degree is high, one person can operate the waste cable recovery device, and the operation is simple.

Owner:董高正

Power distribution cable winding apparatus

InactiveCN106356152AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingStart stopEngineering

The invention discloses a power distribution cable winding apparatus, comprising a base fixedly provided with a weighing instrument; a main frame is mounted on a weighing platform of the weighing instrument, a rotary sleeve is rotationally mounted on the main frame, hinged rockers are circularly and evenly arranged on the lower portion of the rotary sleeve, the middles of the rockers are bent to the center of the rotary sleeve, a center shaft is slidably inserted in the rotary sleeve, a cone with a downward tip is fixed to the lower end of the center shaft, rails corresponding to the rockers are evenly distributed on a conical surface of the cone, an extension block that extends to the corresponding rail is fixed to the middle of the corresponding rocker, an end of each extension block is fitted with a mating part that may move only along the corresponding rail, a main power unit and a lifting unit are mounted on the main frame, a cutting unit is also mounted on the base, and the apparatus also comprises a start-stop device for controlling start and stop of the main power unit and the lifting unit. The power distribution cable winding apparatus enables waste cables to be automatically wound in tight bales, baling is easy, and the apparatus provides automatic precise weighing and automatic throwing, is high in automation level, is operable by a single operator and is simple to operate.

Owner:董高正

Quantitative recovery apparatus for power cables

InactiveCN106158156AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingPower cableStart stop

The invention discloses a quantitative recovery apparatus for power cables. The quantitative recovery apparatus comprises a base, wherein a weighing apparatus is fixedly arranged on the base; a main frame is mounted on a weighing platform of the weighing apparatus; a rotary sleeve is rotationally mounted on the main frame; hinged swing arms are uniformly and annularly arranged at the lower part of the rotary sleeve; the middle parts of the swing arms are bent towards the center of the rotary sleeve; a center shaft is inserted in the rotary shaft in an axial direction glidingly; a conical block with a downward sharp end is fixedly arranged at the lower end of the center shaft; tracks corresponding to the swing arms are uniformly formed in the conical surface of the conical block; extension blocks which extend to the tracks are fixedly arranged on the middle parts of the swing arms; matching parts which can only move along the tracks are mounted on the end parts of the extension blocks; the main frame is provided with a main power apparatus and a lifting apparatus; the base is also provided with a cutting apparatus; and the quantitative recovery apparatus also comprises a starting-stopping apparatus which is used for controlling the starting and stopping of the main power apparatus and the lifting apparatus. By adoption of the quantitative recovery apparatus, waste cables can be wound in bunches automatically and tightly; the cables can be bundled up easily; the cables can be weighted automatically and precisely; automatic material throwing can be carried out; and therefore, the quantitative recovery apparatus is high in automatic degree, simple to operate and can be operated by one person.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

Power cable take-up device

InactiveCN106373679AReasonable structureBundled tightlyBasic electric elementsElectronic waste recyclingPower cableStart stop

The invention discloses a power cable take-up device. The power cable take-up device comprises a base fixedly provided with a weighing apparatus, a weighing platform of the weighing apparatus is provided with a main frame, the main frame is rotationally provided with a rotary sleeve, the outer wall of the rotary sleeve is in the shape of a cone with a thin lower end and a thick upper end, the lower portion of the rotary sleeve is uniformly circumferentially provided with swing arms hinged through horizontal hinge axle, a center shaft is axially slidably inserted into the rotary sleeve, the lower end of the center shaft is annularly provided with support arms, the lower ends of the support arms are hinged to the center shaft, the upper ends of the support arms are hinged to the lower ends of the corresponding swing arms, when the center shaft slides upwards to an upper stroke point, the support arms and the center shaft are vertically arranged, the lower ends of the swing arms are distanced further from the center shaft then the upper ends of the swing arms, when the center shaft slides downwards to a down stroke point, the upper ends of the swing arms are distanced further from the center shaft than the two ends of each support arm, the lower ends of the swing arms are disposed at the outer sides of connecting lines between the upper ends of the swing arms and the lower ends of the swing arms, and the power cable take-up device further comprises a main power apparatus, an elevating apparatus, a cutting apparatus and a start-stop apparatus. According to the invention, waste and old cables can be wound in bundles automatically, bound bundles are tight, binding is facilitated, automatic accurate weighing is realized, automatic material throwing is realized, the automation degree is high, operation can be performed simply by one person, and the operation is simple.

Owner:董高正

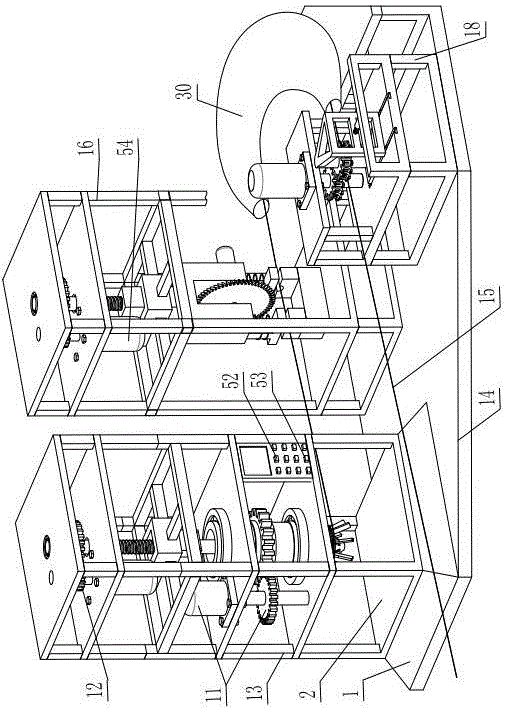

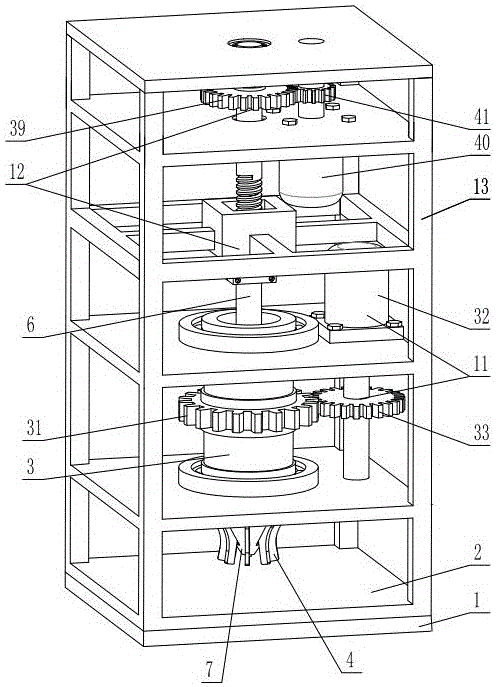

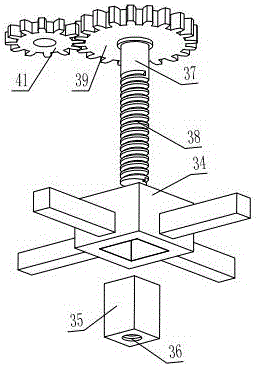

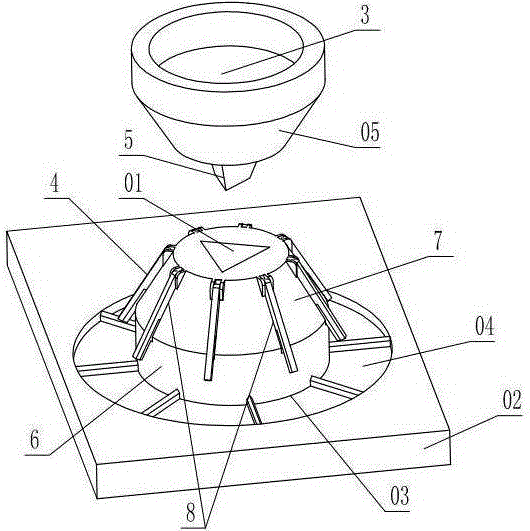

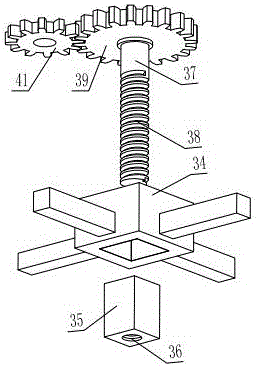

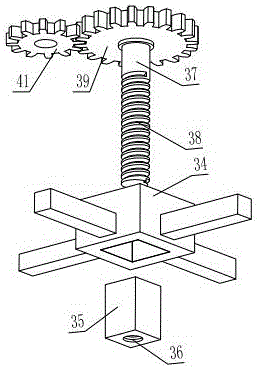

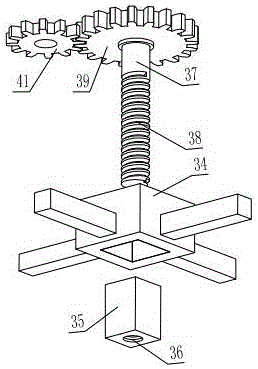

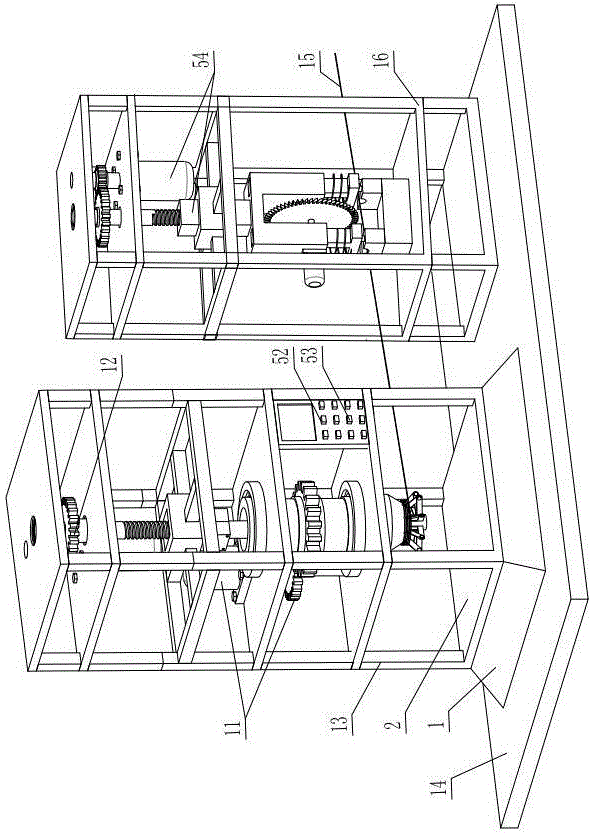

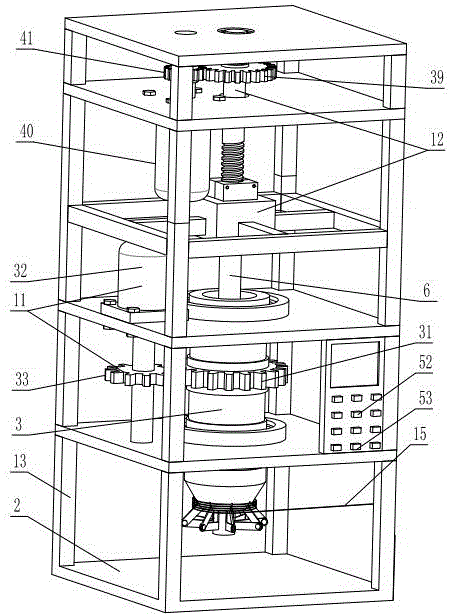

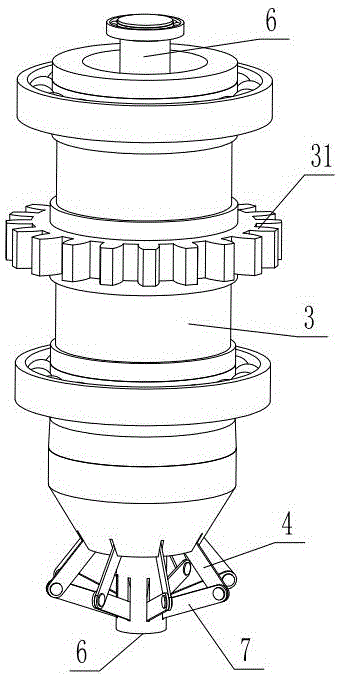

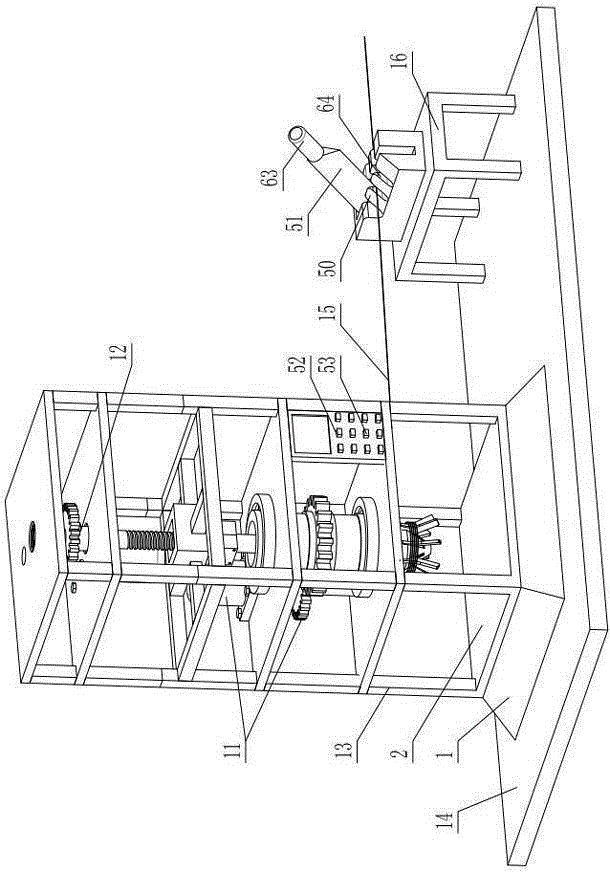

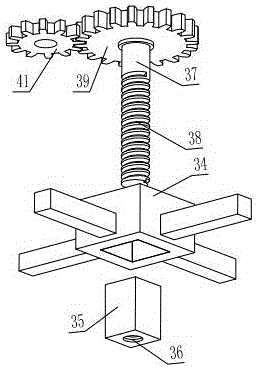

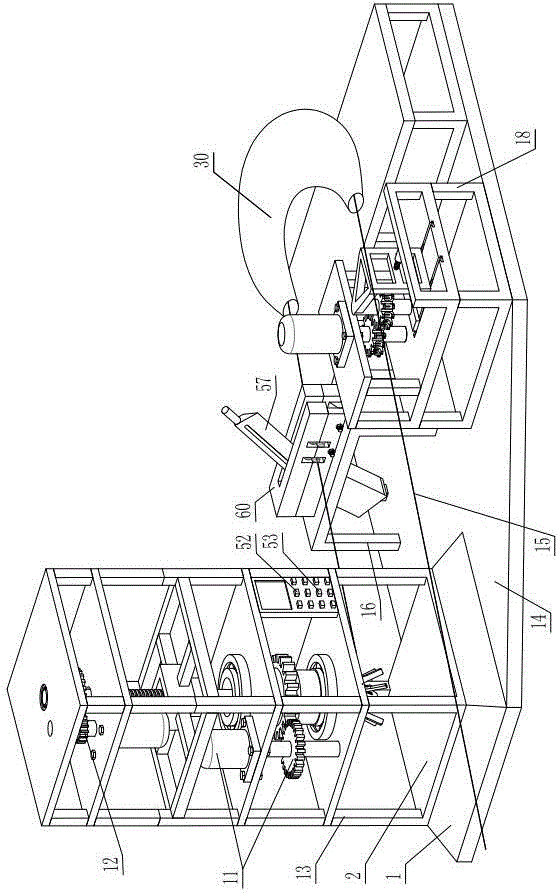

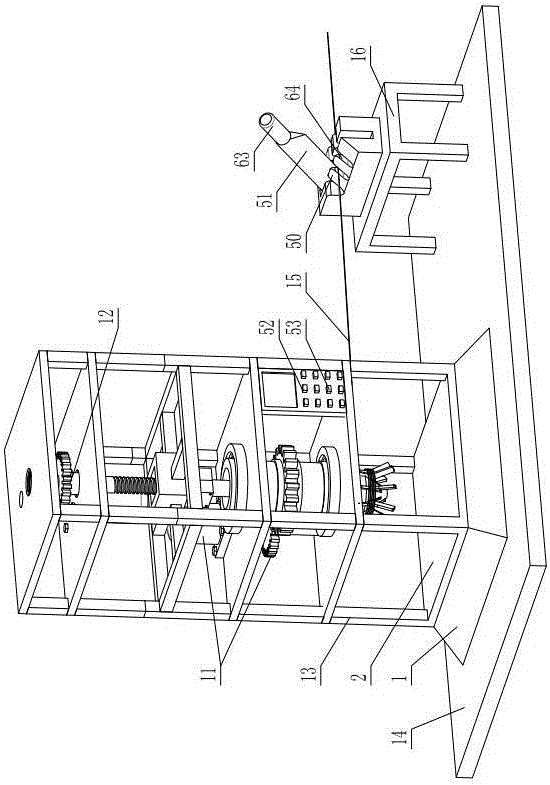

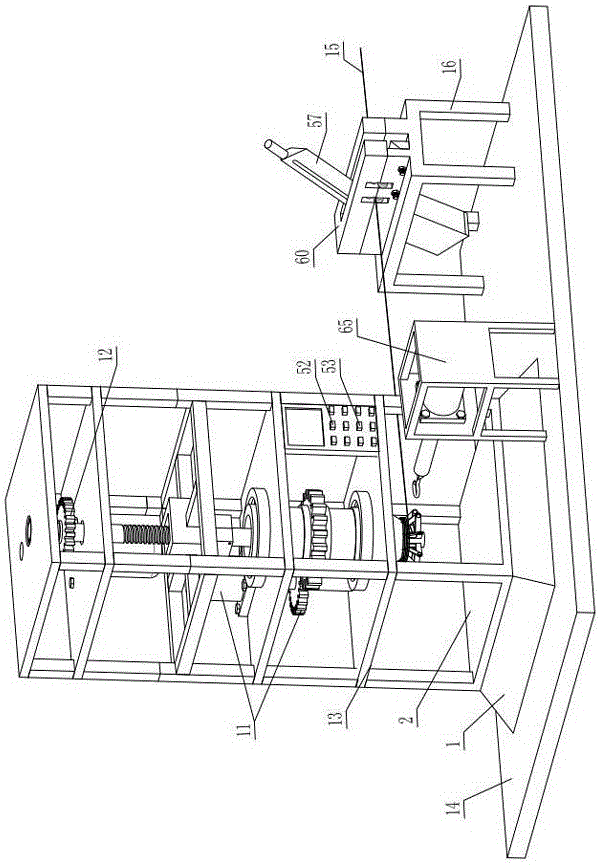

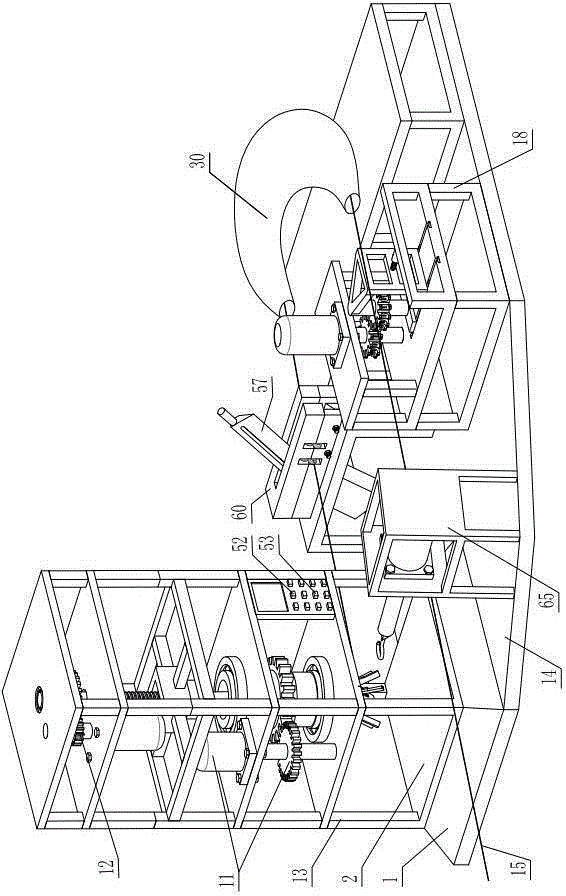

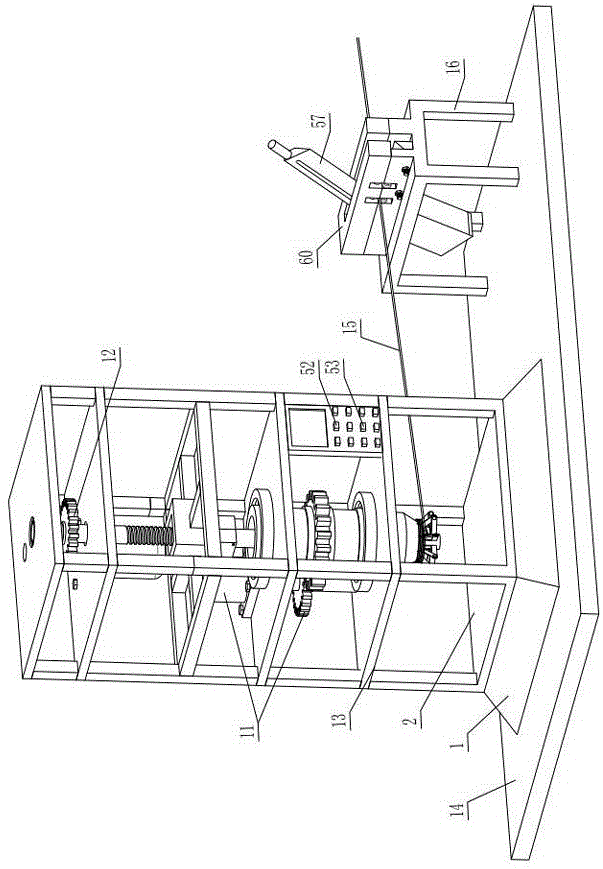

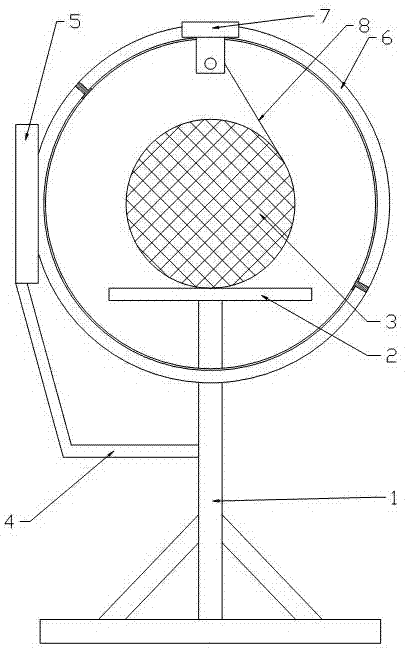

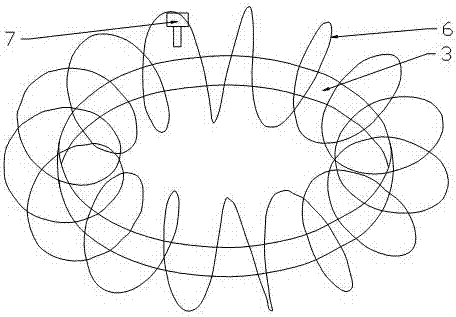

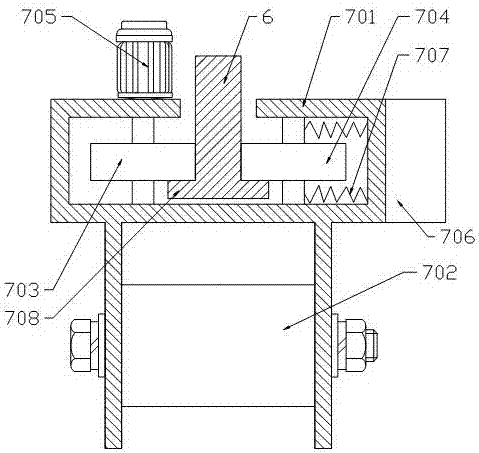

Apex strip bundling device

InactiveCN107187632AIncrease profitReduce wasteBinding material applicationBundling machine detailsEngineeringMechanical engineering

The patent relates to the field of tire manufacturing technological equipment and discloses an apex strip bundling device. The apex strip bundling device is characterized in that support rods in circumferential distribution and bearing platforms are used for placing an apex strip bundle, and the bearing platforms horizontally jack up the apex strip bundle. A spiral rack is rotated to wrap the apex strip bundle in the spiral rack. As the spiral rack is flexible, the spiral rack can be bent and deformed in the length direction while the diameter of the spiral rack is kept unchanged, and after the apex strip bundle is placed in the spiral rack, the spiral rack is circular-ring-shaped. A motor is started to drive a driving roller to rotate; and as the driving roller is propped against the spiral rack, the driving roller drives a bundling head to perform spiral movement along the spiral rack, accordingly, the bundling head continually moves from the outer side of the apex strip bundle to the inner side and then moves from the inner side of the apex strip bundle to the outer side, and further, a packing strap on a packing strap roller is spirally wound on the apex strip bundle to finish bundling of the apex strip bundle. The patent aims to achieve the purpose of bundling the annular apex strip bundle.

Owner:CHONGQING WEIXING RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com