Electric power distribution cable winding machine

A technology of power distribution cable and wire take-up, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve problems such as unfavorable storage, easy scattering, and inaccurate weighing values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

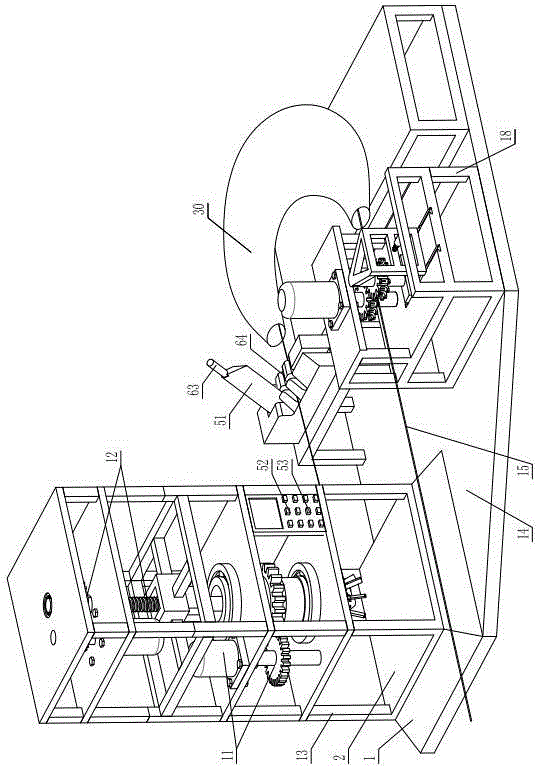

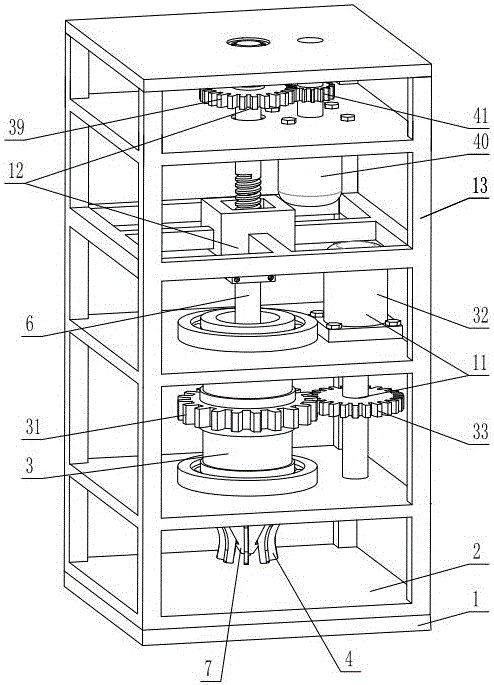

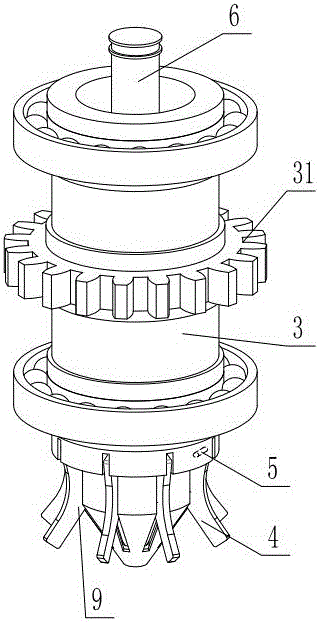

[0037] As shown in the figure, the power distribution cable take-up device includes a base 14 with a weighing instrument 1 fixed on it. A main frame 13 is installed on the weighing platform 2 of the weighing instrument, and a rotating sleeve 3 arranged vertically in the axial direction is installed on the main frame. , the uniform ring at the lower part of the rotary sleeve is provided with a swing arm 4 hinged by a horizontal hinge shaft 5, the middle part of the swing arm is bent toward the center of the rotary sleeve, and a central shaft 6 is inserted in the axial slide of the rotary sleeve, and the lower end of the central shaft is fixed with a point downward The conical block 7, the conical surface of the conical block is evenly distributed with the track 8 corresponding to the swing arm, the middle part of the swing arm is fixed with an extension block 9 extending to the track, and the end of the extension block is installed with a fitting that can only move along the trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com