Wind-up device of power cable

A technology for take-up equipment and power cables, applied in the field of power cable take-up equipment, can solve problems such as being unfavorable for warehouse personnel to count, difficult to take and place cable groups, and large cable groups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

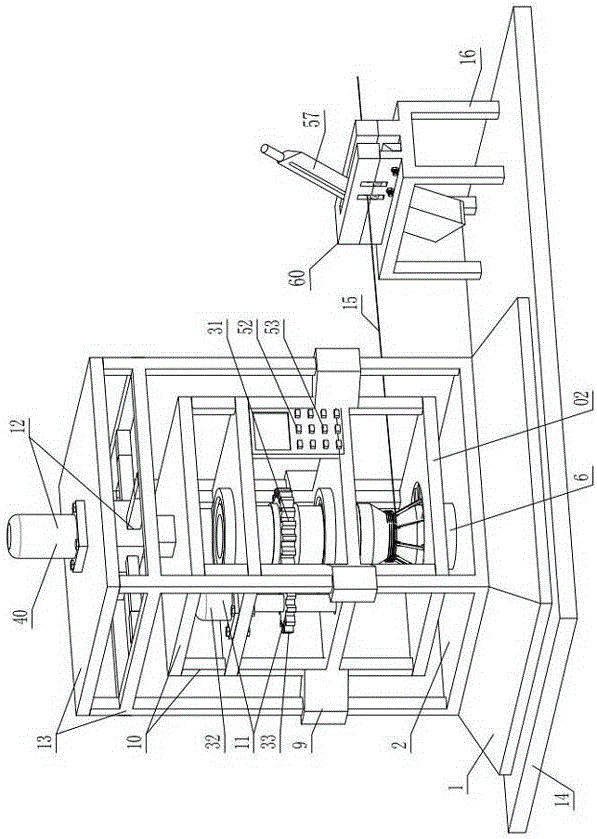

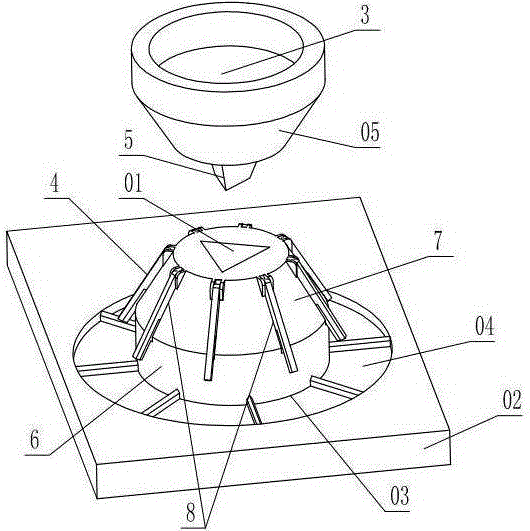

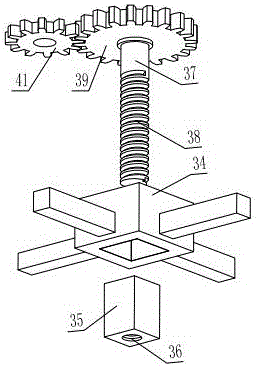

[0020] As shown in the figure, the power cable take-up equipment includes a base 14 fixed with a weighing instrument 1, a main frame 13 is installed on the weighing platform 2 of the weighing instrument, and a cylinder 6 extending upward is fixed in the middle of the weighing platform, and the upper end of the cylinder rotates A lower conical frustum 7 whose upper end is thinner and lower end the same as the cylinder is installed, and the upper end ring of the outer periphery of the lower frustum is provided with a swing arm 4 that is hinged up and down with the lower conical frustum. When the swing arm is located on the outer wall of the lower conical frustum, the lower end of the swing arm extends out of the cylinder. Circumferentially, the outer wall of the lower conical table is evenly distributed with swing arm slots 8 that snap fit with the lower side of the swing arm. The main frame is slidably equipped with a lifting frame 10 through a lifting sleeve 9. The lifting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com