Electric power distribution cable recycling device

A technology of power distribution cables and recycling devices, which is applied in the direction of electronic waste recycling, recycling technology, circuits, etc., and can solve problems such as inaccurate weighing values, easy scattering, and different shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

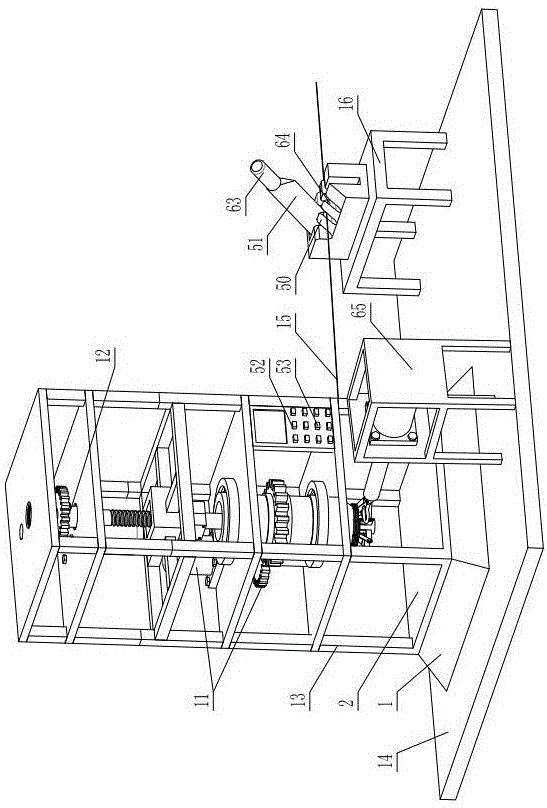

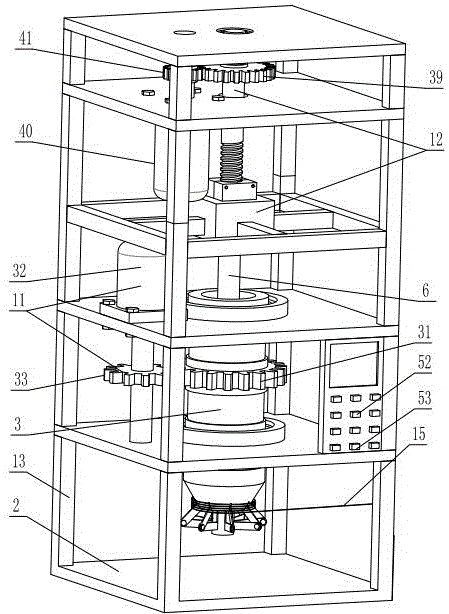

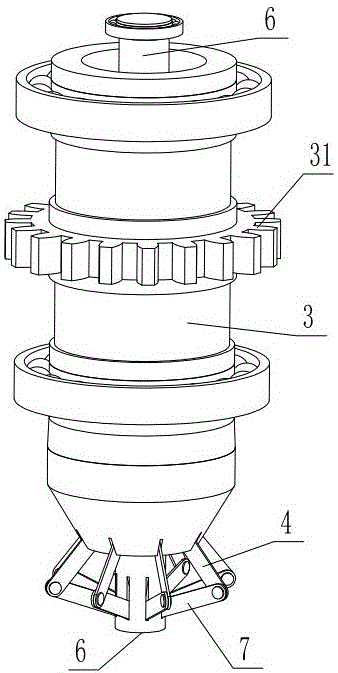

[0022] As shown in the figure, the power distribution cable recovery device includes a base 14 on which a weighing instrument 1 is fixed, a main frame 13 is installed on the weighing platform 2 of the weighing instrument, and a rotating sleeve 3 arranged axially and vertically is rotatably installed on the main frame. The outer wall of the sleeve is in the shape of a cone with a thin lower end and a thick upper end. The lower uniform ring of the sleeve is provided with a swing arm 4 articulated by a horizontal hinge shaft 5. A central shaft 6 is inserted axially in the sleeve, and the lower end ring of the central shaft is provided with The swing arm corresponds to the support arm 7 one by one. The lower end of the support arm is hinged with the central axis, and the upper end of the support arm is hinged with the corresponding lower end of the swing arm. When the central axis slides up to the upper stroke point, the support arm is arranged perpendicular to the central axis. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com