Fine sand sorting machine

A sorting machine and fine sand technology, applied in flotation water/sewage treatment, packaging, etc., can solve problems such as residue and equipment corrosion, and achieve the effect of prolonging service life and thorough sand discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

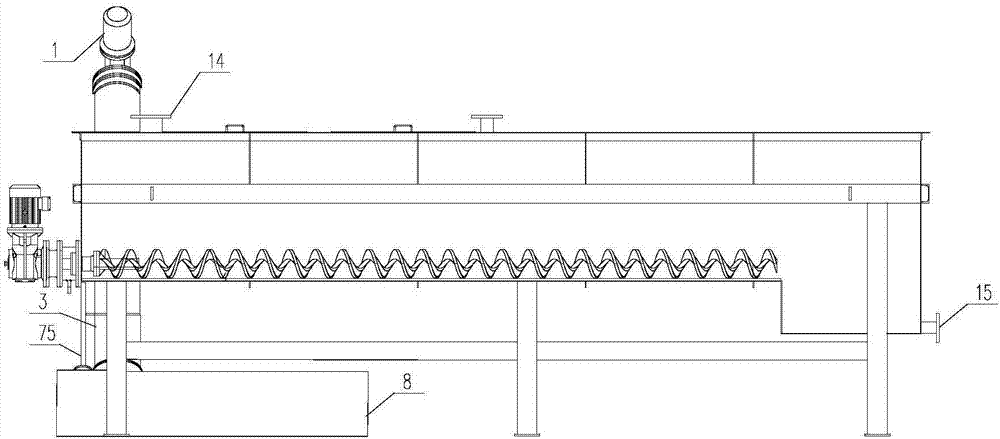

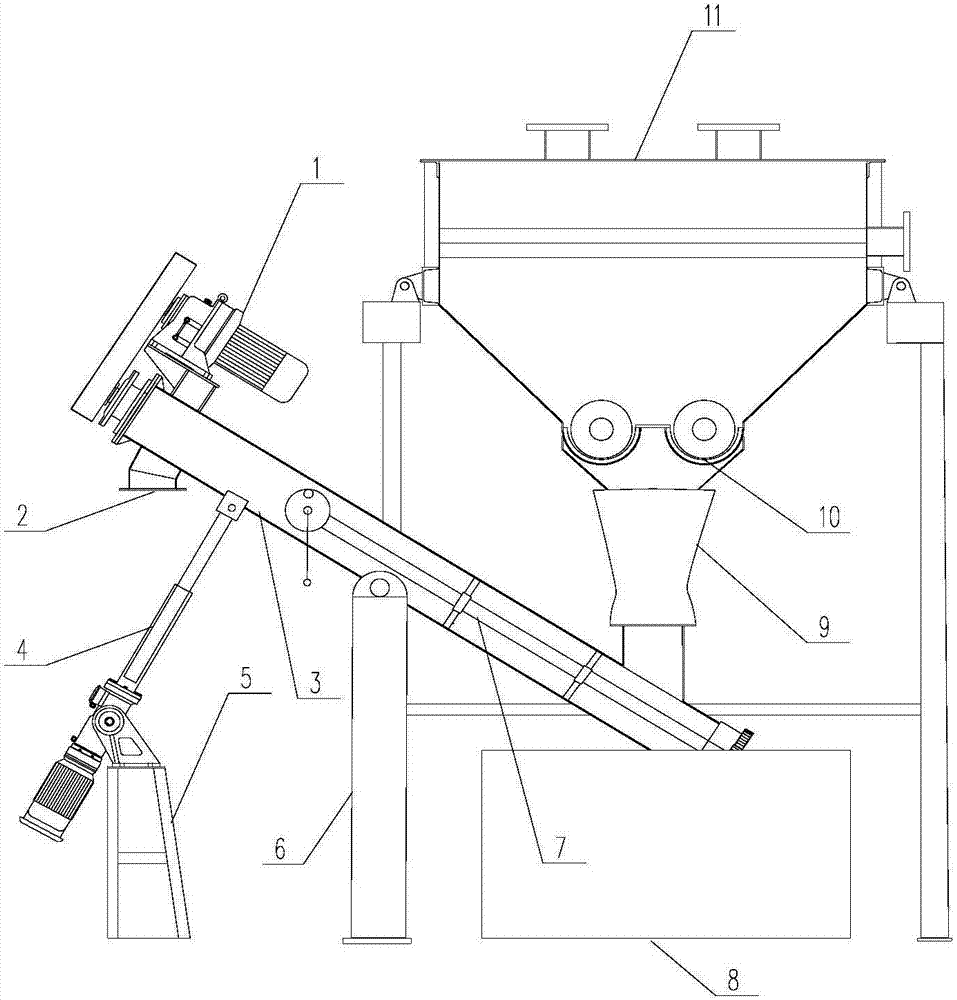

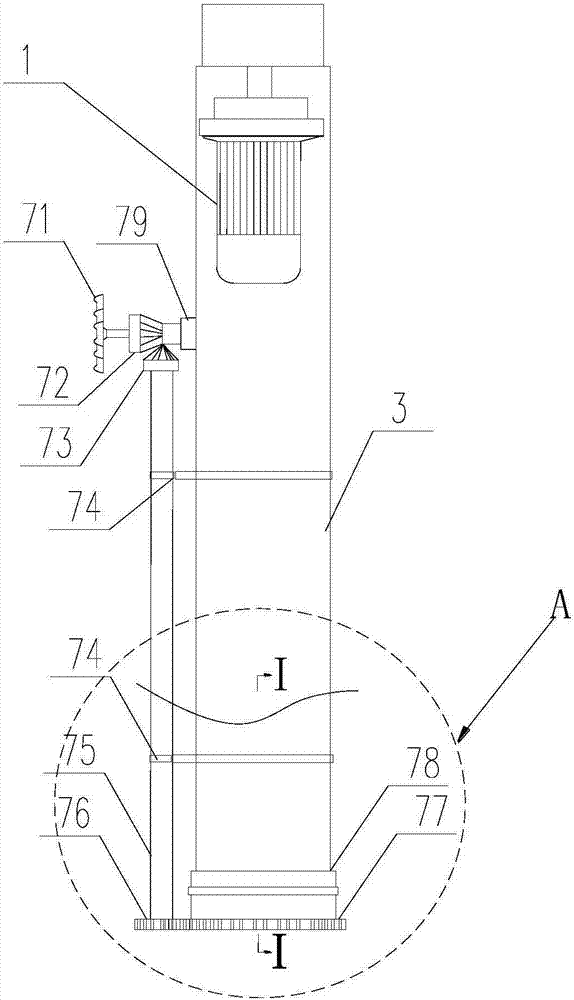

[0018] figure 1 The shown fine sand separator includes a first screw conveyor, a second screw conveyor, a sand-water separation box 11 and a sand discharge mechanism; the top of one end of the sand-water separation box 11 has a slurry inlet 14, A water baffle (not marked in the figure) is arranged in the sand-water separation box 11, and the water baffle is installed on the inner wall of the sand-water separation box 11 through a mounting bracket, and the water baffle is located directly below the slurry inlet 14, so that The slurry entered by the slurry inlet 14 can only impact on the water retaining plate, and an overflow plate (not marked in the figure) is erected on the bottom surface of one end of the sand-water separation box 11, and the overflow plate separates the inner cavity of the sand-water separation box 11 into turbidity. The water chamber and the clean water chamber, the top of the muddy water chamber communicates with the top of the clean water chamber, the cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com