Large-flow aluminum oxide automatic sand cleaning and separating equipment and separating method thereof

A separation equipment, alumina technology, applied in chemical instruments and methods, solid separation, sieves, etc., can solve the problems of large residual impurities, clogging, incomplete sand removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

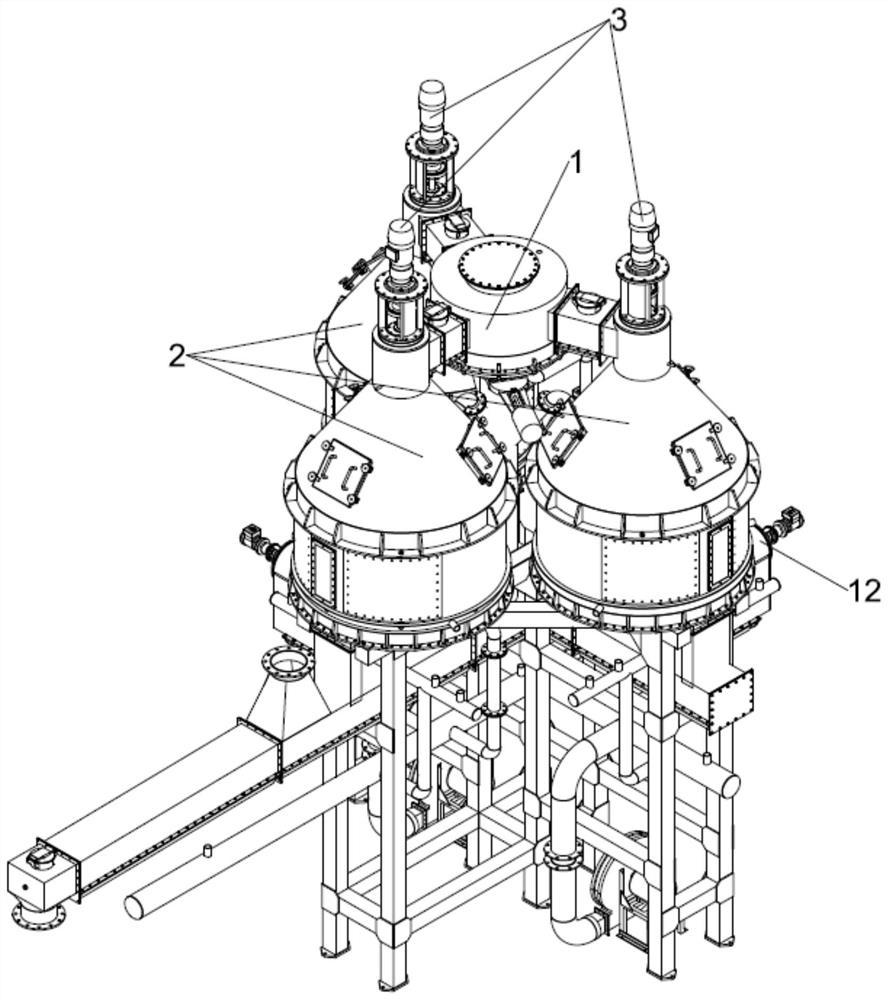

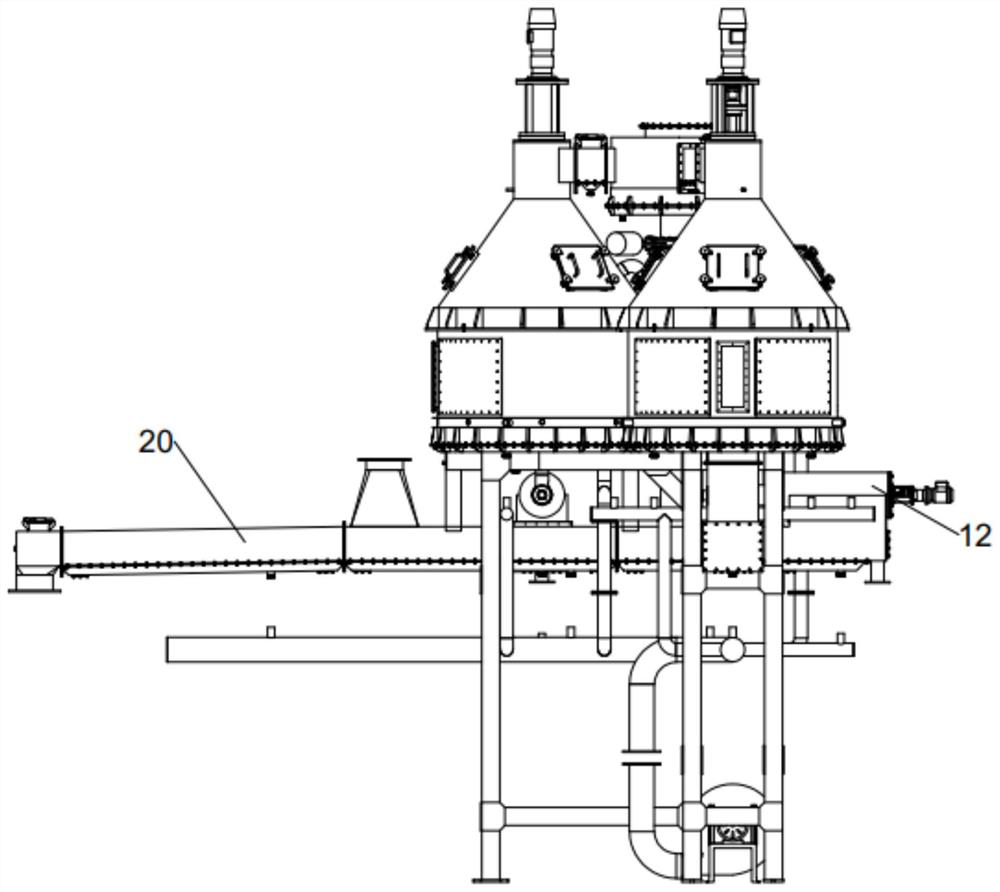

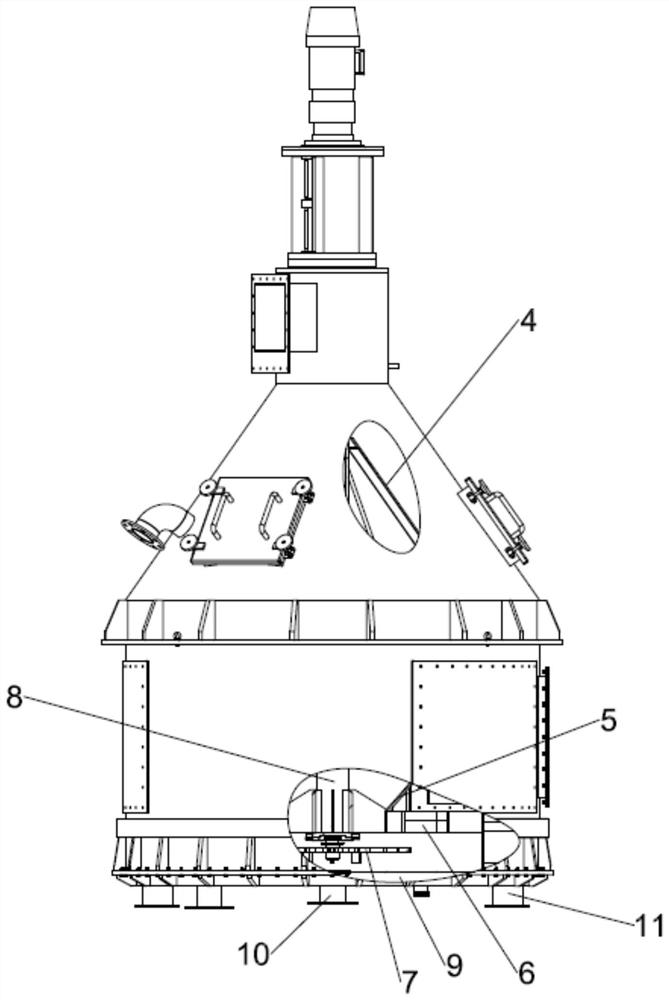

[0037] Such as Figure 1-9As shown, according to a preferred embodiment of the large-flow alumina automatic sand cleaning and separation equipment of the present invention, it includes a material distribution box 1 and three sand removal boxes 2, and the three sand removal boxes 2 are evenly distributed on the material distribution box. around the box 1, and communicate with the distribution box 1 through chute respectively, each chute is provided with a quick opening hole, the bottom of the chute is provided with an air chamber, and the bottom of the distribution box 1 is provided with a distribution air chamber 11 , the material distribution air chamber 11 is connected with the air supply pipeline, the bottom of the material distribution box 1 is connected with the material distribution discharge pipe, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com