A high-elastic double-core yarn production device and production method

A technology of a production device and a production method, applied in the field of spinning, can solve the problems of inability to freely adjust the main draft, poor evenness of the yarn, and low transformation cost, and achieve the effect of excellent core filament covering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

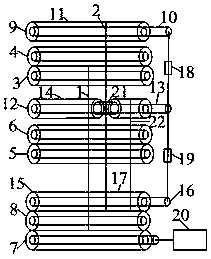

[0011] Depend on figure 1As shown, a high-elastic double-core yarn production device includes a rear draft roller pair composed of a rear roller 3 and a rear rubber roller 4, a middle draft roller pair composed of a middle roller 5 and a middle rubber roller 6, and a front draft roller pair composed of a front roller 5 and a middle rubber roller 6. The front drafting roller pair composed of roller 7 and front rubber roller 8, the rear roller 3 includes the rear roller shaft, the rear roller shaft is a solid cylinder, and the rear roller sleeve is fixedly connected to the rear roller shaft, and the rear rubber roller 4 includes the rear roller shaft. The rubber roller shaft, the rear rubber roller shaft is a solid cylinder, the rear rubber roller sleeve is connected to the rear rubber roller shaft through bearings, the diameter of the rear rubber roller sleeve remains unchanged and can rotate freely along the rear rubber roller shaft, the middle roller 5 includes the middle rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com