Width-variable wood-plastic door pocket assembly

An adjustable and component technology, applied in the direction of window/door frame, etc., can solve the problems of non-adjustable size, complicated installation and operation, and inability to recycle, and achieve the effect of reducing economic loss, convenient and simple operation, and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

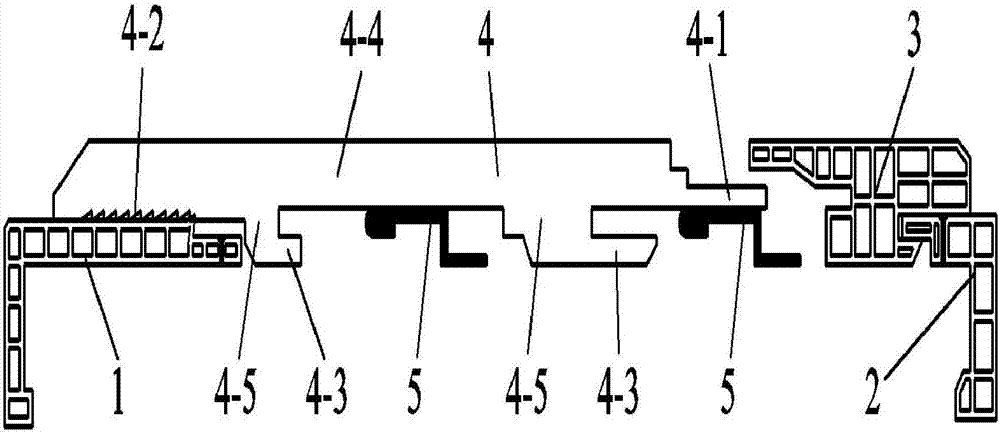

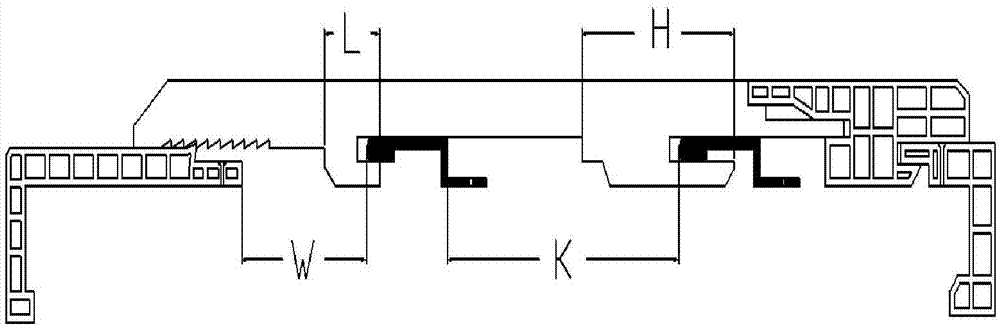

[0036] Specific Embodiment 1: Combining figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 To illustrate this embodiment, the wood-plastic door cover assembly with adjustable width in this embodiment includes an L-shaped profile a1, a Z-shaped connector 5, an L-shaped profile b2, an I-shaped pluggable profile 3 and an adjustable plug-in component 4 ; The L-shaped profile a1, the L-shaped profile b2, the I-shaped pluggable profile 3 and the adjustable plug-in cover part 4 are all made of wood-plastic composite materials, and the wood-plastic composite materials are made by extrusion molding process; The L-shaped profile a1 and the L-shaped profile b2 can be fixedly connected to the wall, and the L-shaped profile a1 is provided with an anti-reverse component; the Z-shaped connector 5 can also be fixedly connected to the wall;

[0037] The adjustable plug-in part 4 has a horizontal base surface 4-4, and the two ends of the horizontal base surface 4-4 are respectively p...

specific Embodiment approach 2

[0039] Specific Embodiment 2: Combining Figure 4 and Figure 5 This embodiment is described. The difference between this embodiment and the specific embodiment 1 is that the section of the L-shaped profile a1 has at least one long side and one short side, and the long side and the short side are connected at one end. An anti-reverse component is provided on the end of the long side away from the short side, and the L-shaped profile a1 also has at least one connecting portion, which can be fixedly connected to the wall through a connecting piece, and the connecting portion located on said long side, short side, or an extension of said long side and short side;

[0040] The section of the L-shaped profile b2 has at least two sides, the two sides are connected at one end and the length of the two sides is similar, and the L-shaped profile b2 also has at least one connecting part, and the connecting part is passed The connecting piece can be fixedly connected to the wall, and t...

specific Embodiment approach 3

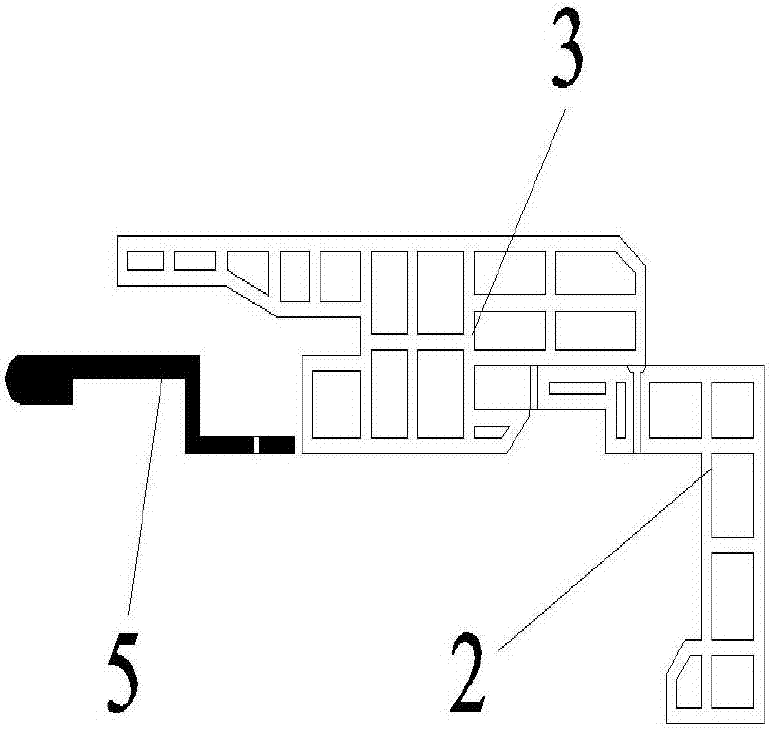

[0041] Embodiment 3: Combining figure 1 , figure 2 , image 3 , Image 6 and Figure 7 Describe this embodiment. The difference between this embodiment and the specific embodiment 1 or 2 is that the Z-shaped connector 5 has two parallel planes, and the two parallel planes are connected by a vertical surface. Two parallel planes are respectively located on both sides of the facade, wherein at least one of the planes has an arc-shaped end section far away from the facade, and the arc-shaped end is inserted into the adjustable plug-in part 4. The mating part is plugged in; the elevation is perpendicular to the two parallel planes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com