Railway yard electrified section pipe paving construction method

A technology for railway stations and pipelines, which is applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve the problems of inability to use open-cut construction, high labor intensity, and inability to open-cut, etc., to achieve shortening The construction period, construction efficiency improvement, and the effect of ensuring construction safety and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

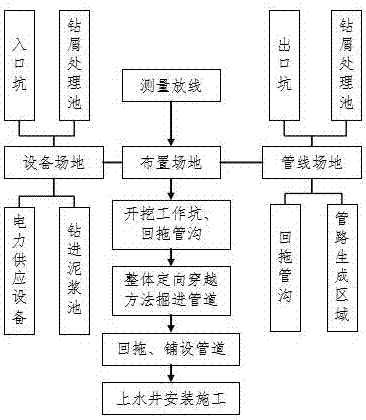

[0072] Such as figure 1 with figure 2 As shown, the construction method of pipe laying in the electrified section of the railway station yard includes the following steps:

[0073] a. Measure and pay off;

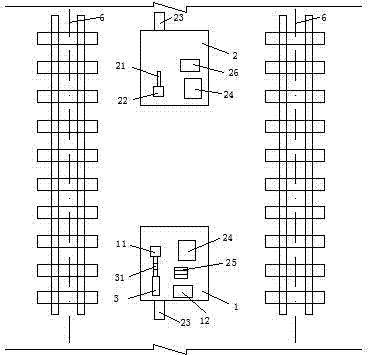

[0074] b. Layout site, including equipment site 1 and pipeline site 2 at both ends of railway line 6;

[0075] c. Excavation, excavation of working pits and return pipe trench 21, working pits including entrance working pit 11 and unearthed working pit 22;

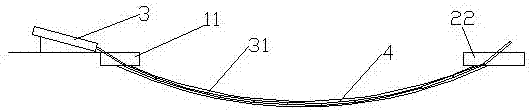

[0076] d. To excavate the pipe hole, use the method of overall directional crossing to excavate the pipe hole,

[0077] e. Lay the pipeline, connect the pipeline to be laid with the tunneling equipment at the excavation point, and drag the pipeline back to complete the laying.

[0078] In this embodiment, an old station is taken as an example for description. The station includes multiple lines, the catenary above the line has also been connected to the network for power transmission, and some lines are still used for transportat...

Embodiment 2

[0112] In this embodiment, the installation of the upper water well is carried out on the basis of the pipeline laying in embodiment 1. Step e specifically includes the following steps:

[0113] f1. Excavation, excavate the well to a predetermined depth;

[0114] f2. Lay cushion under the well site pipeline;

[0115] f3. Masonry well chamber, install prefabricated shaft;

[0116] f4. Install water supply and drainage pipes;

[0117] f5. Pipeline test. Tightness test for water supply pipeline, using water pressure test or air pressure test.

[0118] In step f1, when the well site is excavated, due to the intricacies of underground cables, optical cables, and existing pipelines, it needs to be confirmed in advance, using the previously constructed underground cables, optical cables and existing pipelines, and at the same time organize the operators according to the standard Dig and set up trenches for the pipeline vertically and horizontally, find construction obstacles and let the proper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com