Receiver and assembly process thereof

A receiver and installation cavity technology, applied in the field of receivers, can solve the problem that the receiver cannot realize two different types, and achieve the effects of improving electromagnetic conversion efficiency, good quality, beautiful and saturated sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

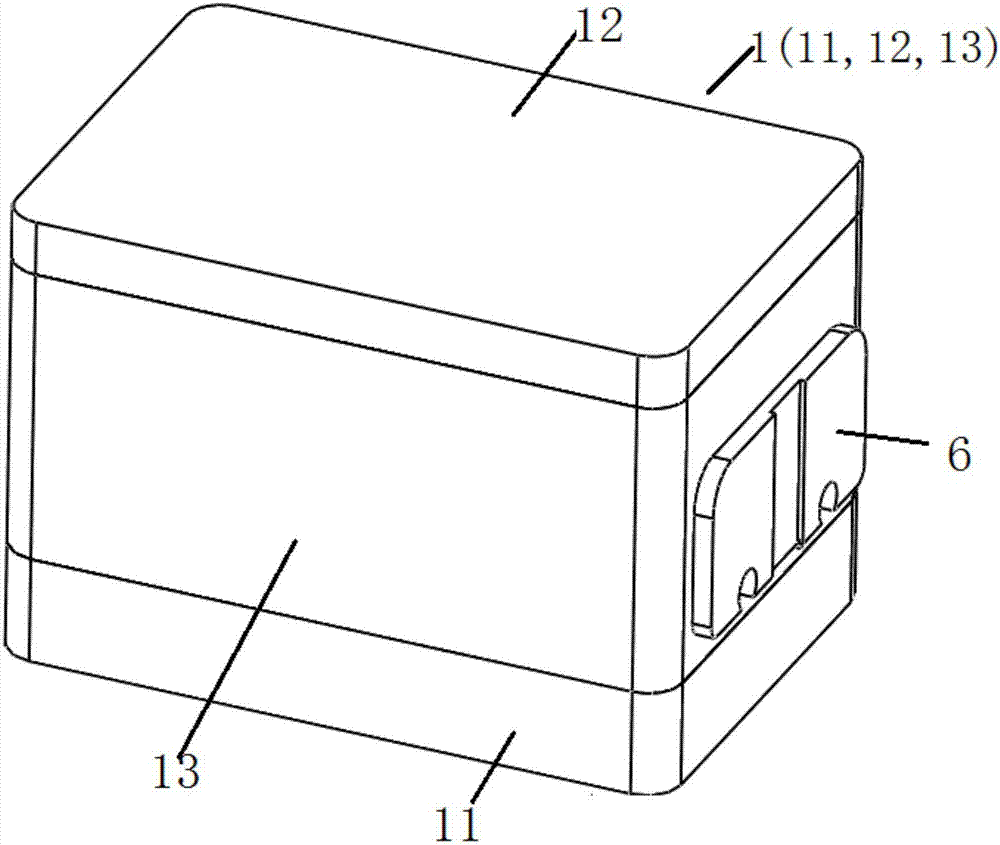

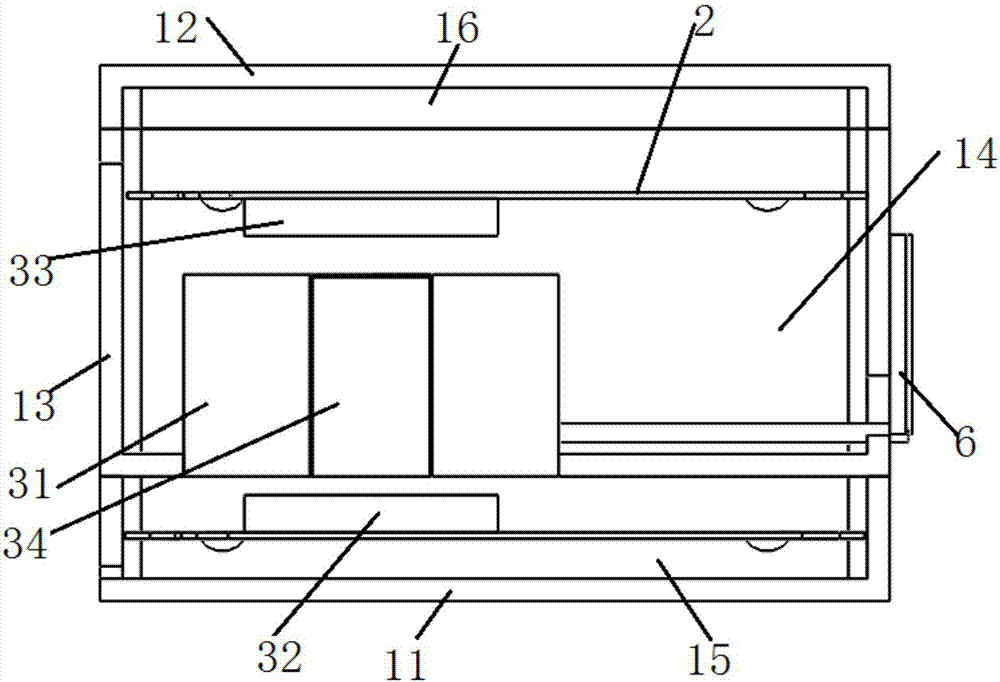

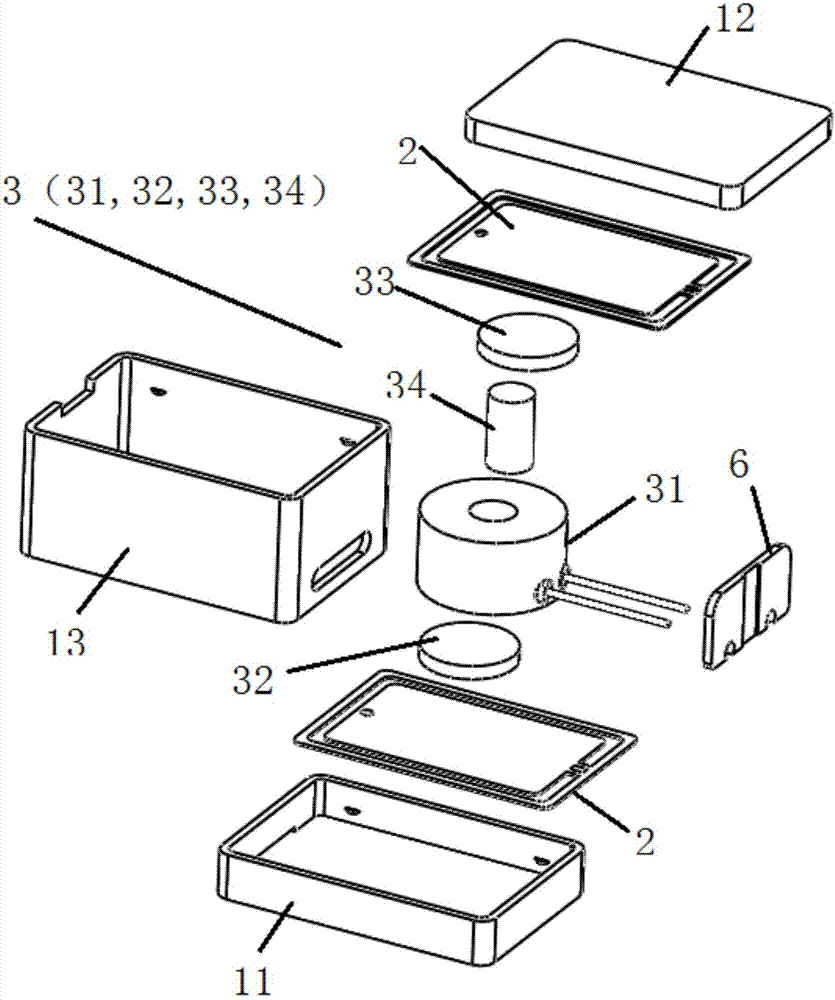

[0070] This embodiment provides a receiver, such as Figure 1 to Figure 3 As shown, it includes a housing 1 , a set of vibration mechanisms, a set of electromagnetic drive mechanisms 3 , sound pipes 5 and welding pads 6 .

[0071] Such as figure 1 and figure 2 , the shell 1 includes a first shell 11 , a second shell 12 and a third shell 13 . The first housing 11 is composed of a first bottom surface and a side wall; the second housing 12 is composed of a second bottom surface and a side wall; the third housing 13 is composed of a third bottom surface and a side wall, and is arranged on the first housing. Between 11 and the edge of the second housing 12 , one end of the third housing 13 facing the second bottom surface is open, and the third bottom surface facing the first bottom surface is provided with an installation hole suitable for installing the coil 31 .

[0072] Such as figure 2 As shown, the vibration mechanism includes two diaphragm mechanisms 2 arranged in par...

Embodiment 2

[0105] This embodiment provides an assembly process of a receiver, which includes a first housing 11, a second housing 12, a third housing 13, a coil 31, a first magnet 32, a second magnet 33, and two diaphragm mechanisms 2 and the magnetization component 34. The assembly process of the receiver comprises the following steps:

[0106] S1: Fix the first magnet 32 on the side surface of the reed 21 in the first diaphragm mechanism 2 facing away from the sound diaphragm 23, and then install the first diaphragm mechanism 2 on the inner wall surface of the first housing 11 , the sound membrane 23 faces the side of the first bottom surface of the first casing 11 to form a first module;

[0107] S2: Install the magnetization component 34 in the inner cavity of the coil 31 in advance, and install the coil 31 on the installation hole of the third housing 13;

[0108] The second magnet 33 is fixed on the side surface of the reed 21 facing away from the sound membrane 23 in the diaph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com