An adsorbent for removing low-density lipoprotein from blood and its preparation method

A low-density lipoprotein and adsorbent technology, applied in blood circulation treatment, chemical instruments and methods, suction devices, etc., can solve the problems of complicated operation, rare antibodies, and high price, and achieve good biocompatibility and cheap raw materials And easy to obtain, the effect of preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

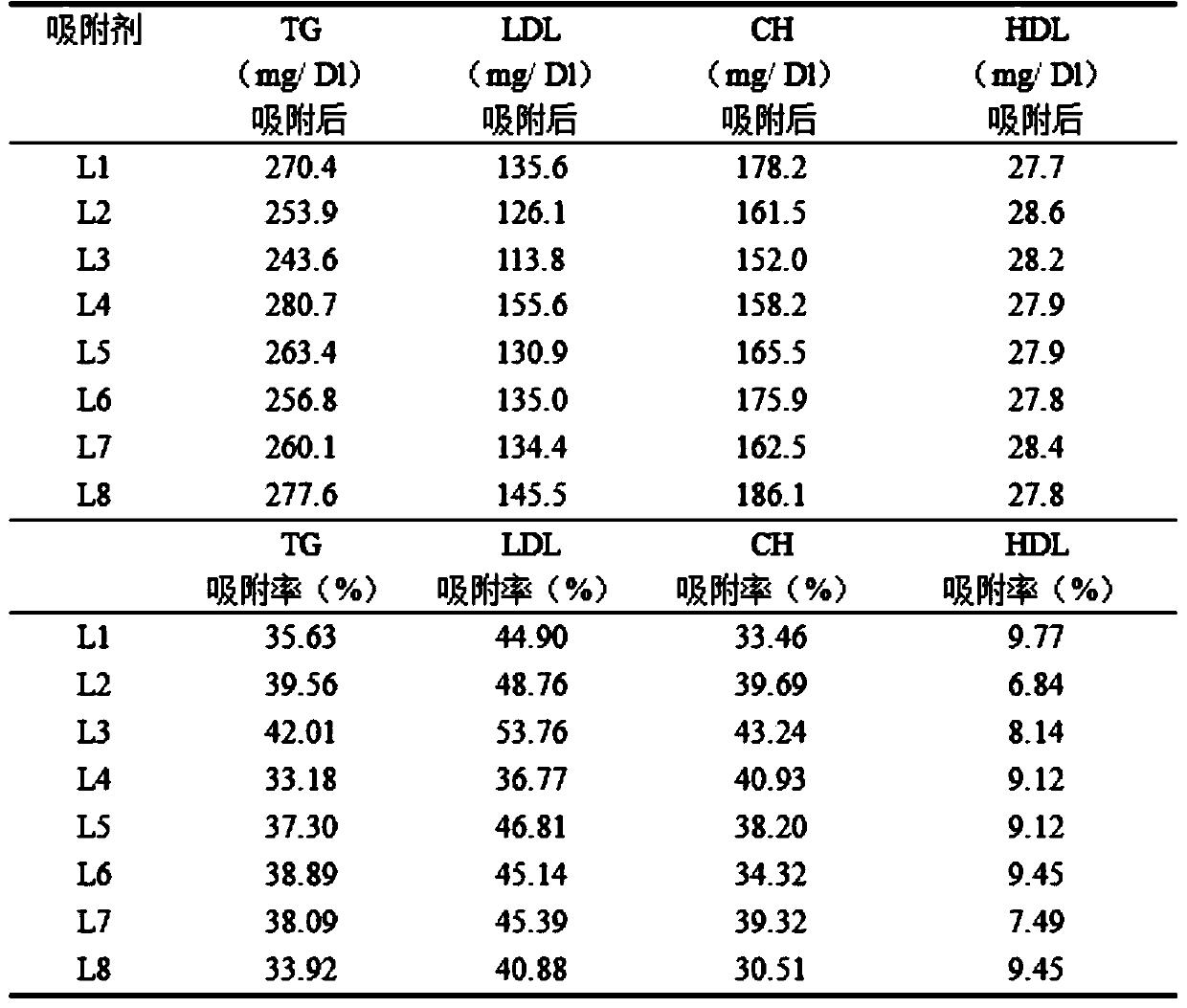

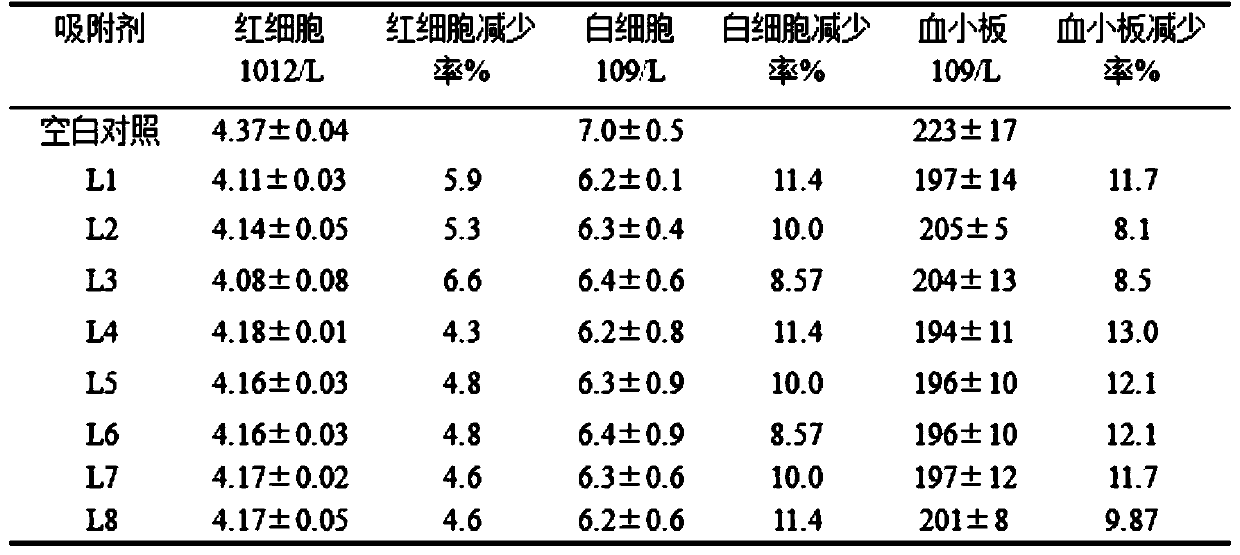

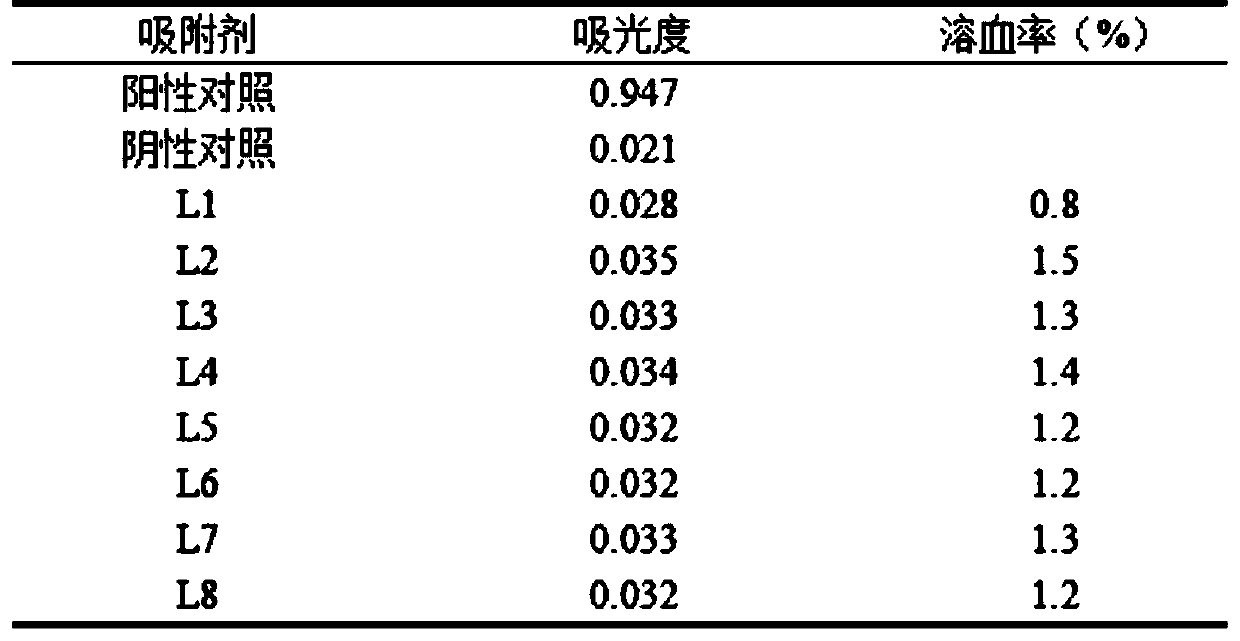

Examples

preparation example Construction

[0020] A method for preparing an adsorbent for removing low-density lipoprotein from blood includes the following steps:

[0021] (1) Diepoxy activation: Place 10-30mL of solid porous cellulose microspheres in a 50mL or 100mL round-bottomed flask, and add 10-30mL dimethyl sulfoxide (DMSO), 5-10mL 1.0mol / L NaOH solution, 5-20mL 1,4-butanediol diglycidyl ether (BDE), stirred at 20-40℃ for 2-8h. After the reaction is completed, take out suction filtration, first wash with 50% acetone solution until no BDE remains, and finally wash with distilled water until no acetone remains.

[0022] (2) Coupling of hydrophobic ligands: Place the porous microspheres prepared in step (1) in a 50mL or 100mL round-bottom flask, add 5-15mL DMSO, 5-15mL 0.5mol / L NaOH solution and 1 ~10g α-tocopherol, stirred at 20~50℃ and protected from light for 4~24h. After the reaction is completed, first wash the unreacted α-tocopherol with a 50% ethanol solution, and then wash it with distilled water.

[0023] (3) ...

Embodiment 1

[0027] Place 10mL of the settled porous cellulose microspheres in a 50mL Erlenmeyer flask, add 10mL of DMSO, 10mL of 1.0mol / L NaOH solution, and 5mL of 1,4-butanediol diglycidyl ether ( BDE), react at 25°C for 4h. After the reaction is completed, take out suction filtration, first wash with 50% acetone solution until no BDE remains, and finally wash with distilled water until no acetone remains.

[0028] The activated porous microspheres were placed in a 50 mL Erlenmeyer flask, and 5 mL of DMSO, 5 mL of 0.5 mol / L NaOH solution and 2 g of α-tocopherol were added, and the reaction was stirred for 12 hours at 30°C and protected from light. After the reaction is complete, first wash the unreacted α-tocopherol with 50% ethanol solution, then wash it with distilled water, transfer it to an Erlenmeyer flask, and add 5 mL of dimethyl sulfoxide (DMSO) and 5 mL of 2.0 mol / L NaOH solution and 2 mL of epichlorohydrin were stirred and reacted at 40° C. for 3 h. After the reaction is comple...

Embodiment 2

[0031] Put 5mL of the settled porous cellulose microspheres in a 50mL Erlenmeyer flask, add 5mL DMSO, 2mL 1.0mol / L NaOH solution, 1mL 1,4-butanediol diglycidyl ether ( BDE), react at 30°C for 6h. After the reaction is completed, take out suction filtration, first wash with 50% acetone solution until no BDE remains, and finally wash with distilled water until no acetone remains.

[0032] Place the activated porous microspheres in a 50 mL Erlenmeyer flask, add 5 mL of DMSO, 3 mL of 0.5 mol / L NaOH solution and 1 g of α-tocopherol, and stir for 15 hours at 40° C. and avoid light. After the reaction is complete, first wash the unreacted α-tocopherol with 50% ethanol solution, then wash it with distilled water, transfer it to an Erlenmeyer flask, and add 5 mL of dimethyl sulfoxide (DMSO) and 5 mL of 2.0 mol / L NaOH solution and 1 mL of epichlorohydrin were stirred and reacted at 40° C. for 2.5 h. After the reaction is completed, take out suction filtration, first wash with 50% aceton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com