Double-roller crusher

A crusher, double-roller technology, applied in the field of double-roller crushers, can solve the problem of material entering between the rollers and the wall of the frame, and achieve the effect of reducing the probability of replacement, simple installation and disassembly, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

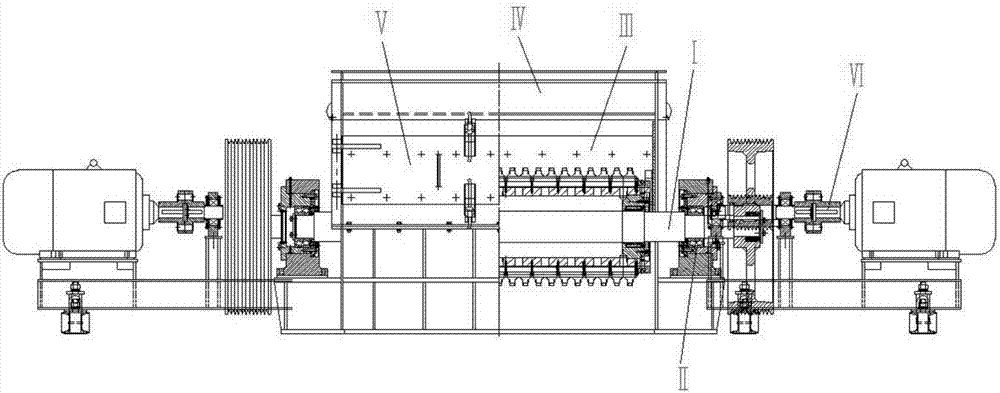

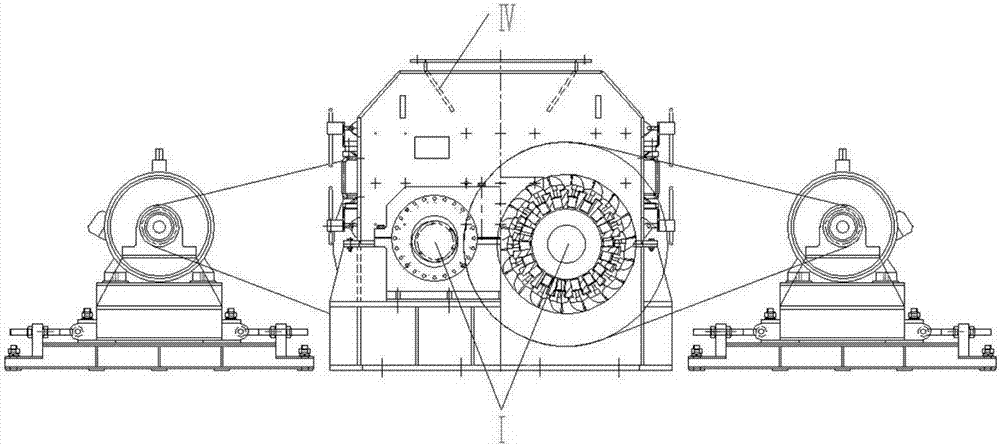

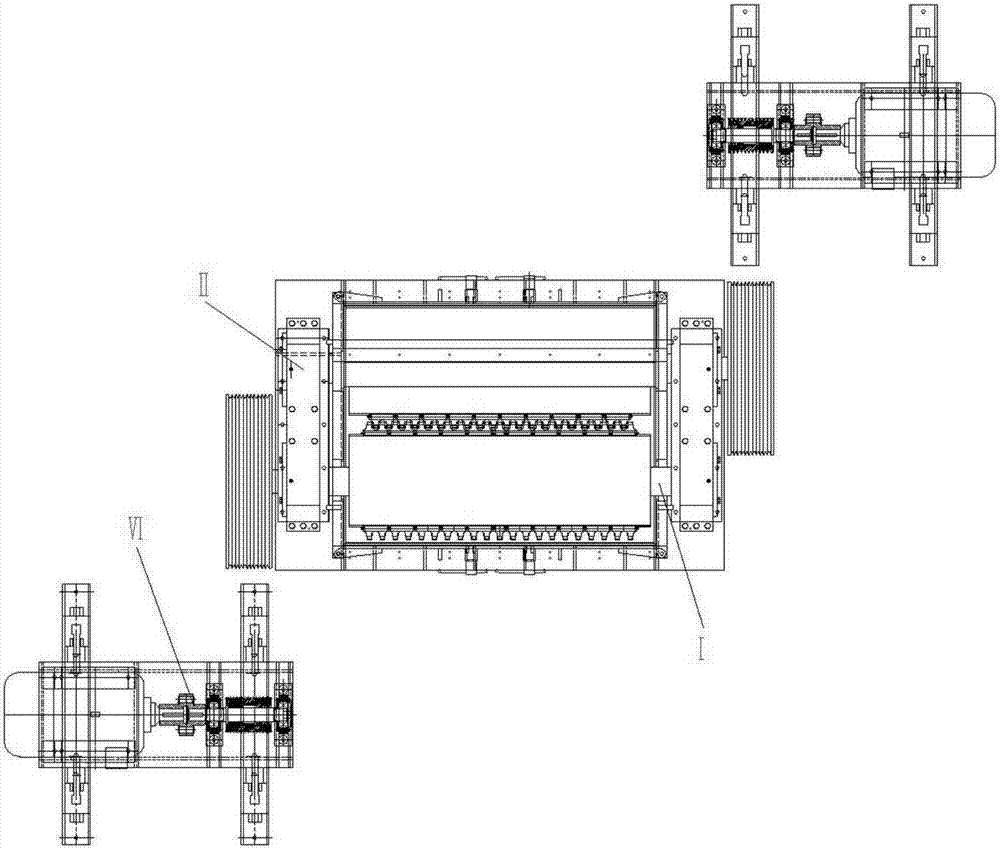

[0103] see Figure 1 to Figure 8 , Figure 12 to Figure 38 . The double-roller crusher in this embodiment includes two main shafts I, two toothed rollers, a frame with a crushing chamber, a double-roller spacing adjustment device II, a liner device III, a material guide structure IV, and a side door V. Motor protection device VI.

[0104] The main shaft I in this embodiment includes the first shaft body I1, the second shaft body I2, the third shaft body I3, the fourth shaft body I4, the fifth shaft body I5, the sixth shaft body I6, The seventh axis body I7, the eighth axis body I8 and the ninth axis body I9. The sides of the nine shafts in this embodiment are not provided with mounting holes and / or keyways, and the mounting holes include screw holes, through holes, special-shaped holes, etc.; the first shaft I1 in this embodiment is connected to the No. 1 bearing II1 , the seventh shaft I7 is connected in the second bearing II7. The third shaft body I3, the fourth shaft b...

Embodiment 2

[0134] see Figure 1 to Figure 5 , Figure 9-Figure 12 . The double-roller crusher in this embodiment includes two main shafts I, two toothed rollers, a frame with a crushing chamber, a double-roller spacing adjustment device II, a liner device III, a material guide structure IV, and a side door V. Motor protection device VI.

[0135] The toothed roller in this embodiment is suitable for fine crushing, and includes a roller and a plurality of toothed plates 2 . The roll includes a roll body 1 . The tooth plate 2 is fixed on the surface of the roller body 1 . The surface of the roller body 1 is provided with several tooth installation grooves 11 along the axial direction of the roller body 1 (direction of the central axis 14). The positioning hole 12 of positioning, the shape of the positioning hole 12 is a cone shape, the diameter of the upper opening of the positioning hole 12 is greater than the diameter of the lower opening of the positioning hole 12, and the upper ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com