Butyl rubber sealant for hollow glass and preparation method of butyl rubber sealant

A technology of butyl rubber and sealant, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of hollow glass failure, not having too high cold flow, affecting the use effect, etc., and achieve good sealing effect , The effect of low water vapor transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

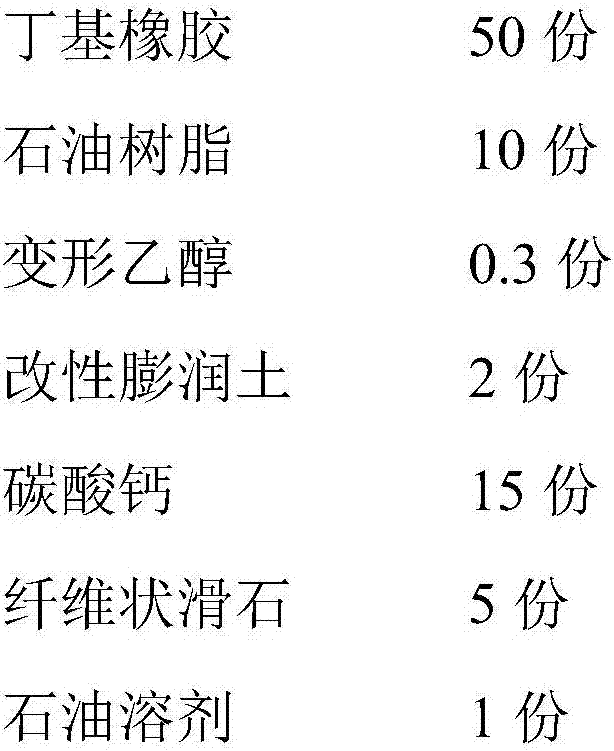

Embodiment 1

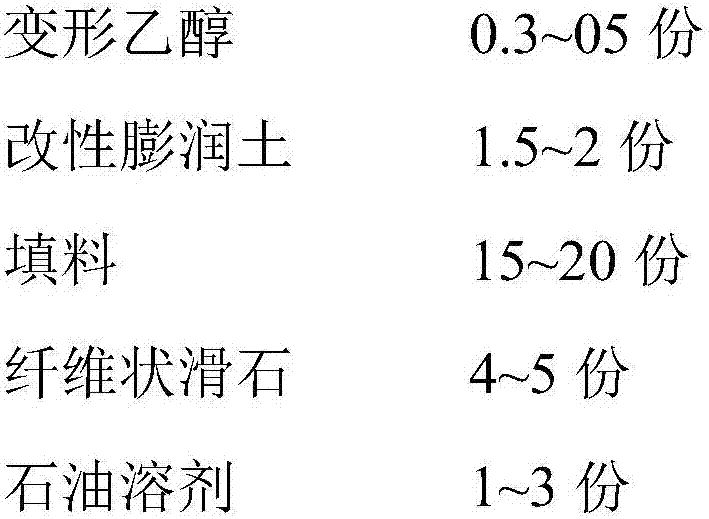

[0017]

[0018] This embodiment provides a preparation method of butyl rubber sealant for insulating glass, comprising the following steps:

[0019] Put 50 parts of butyl rubber, 10 parts of petroleum resin, 0.3 parts of deformed ethanol, and 1 part of petroleum solvent that have been crushed on the open mill into the gravity kneader, start the heater, and when the oil temperature reaches 200-220 ° C, keep warm Start the kneader after 30-50 minutes, open the cover after kneading for 2 hours, put 1.5 parts of modified bentonite, 15 parts of calcium carbonate, and 5 parts of fibrous talc into the kneader and knead for 1.5-3 hours, then start vacuuming. When it reaches 0.085Mpa, start counting, continue kneading for 120 minutes, extrude, shape, and cool to obtain butyl rubber sealant for insulating glass.

Embodiment 2

[0021]

[0022] This embodiment provides a preparation method of butyl rubber sealant for insulating glass, comprising the following steps:

[0023] Put 55 parts of butyl rubber, 12 parts of petroleum resin, 0.3 parts of deformed ethanol, and 1 part of petroleum solvent that have been crushed on the open mill into the gravity kneader, start the heater, and when the oil temperature reaches 200-220 ° C, keep warm Start the kneader after 30-50 minutes, open the cover after kneading for 2 hours, put 1.5 parts of modified bentonite, 20 parts of calcium carbonate, and 4 parts of fibrous talc into the kneader and knead for 1.5-3 hours, then start vacuuming. When it reaches 0.08Mpa, start counting, continue kneading for 150 minutes, extrude, shape, and cool to obtain butyl rubber sealant for insulating glass.

Embodiment 3

[0025]

[0026] This embodiment provides a preparation method of butyl rubber sealant for insulating glass, comprising the following steps:

[0027] Put 60 parts of butyl rubber, 15 parts of petroleum resin, 0.5 parts of deformed ethanol and 1 part of petroleum solvent that have been crushed on the open mill into the gravity kneader, start the heater, and when the oil temperature reaches 200-220 ° C, keep warm Start the kneader after 30-50 minutes, open the cover after kneading for 2 hours, put 2 parts of modified bentonite, 18 parts of calcium carbonate, and 5 parts of fibrous talc into the kneader and knead for 1.5-3 hours, then start vacuuming. When it reaches 0.095Mpa, start counting, continue kneading for 150 minutes, extrude, shape, and cool to obtain butyl rubber sealant for insulating glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap