Independent isolated flushing system with double-end-surface mechanical seal for centrifugal pump

A technology of mechanical seals and flushing systems, applied to mechanical equipment, parts of pumping devices for elastic fluids, pumps, etc., can solve problems such as high risk, prone to major safety accidents, short service life, etc., and achieve impact low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

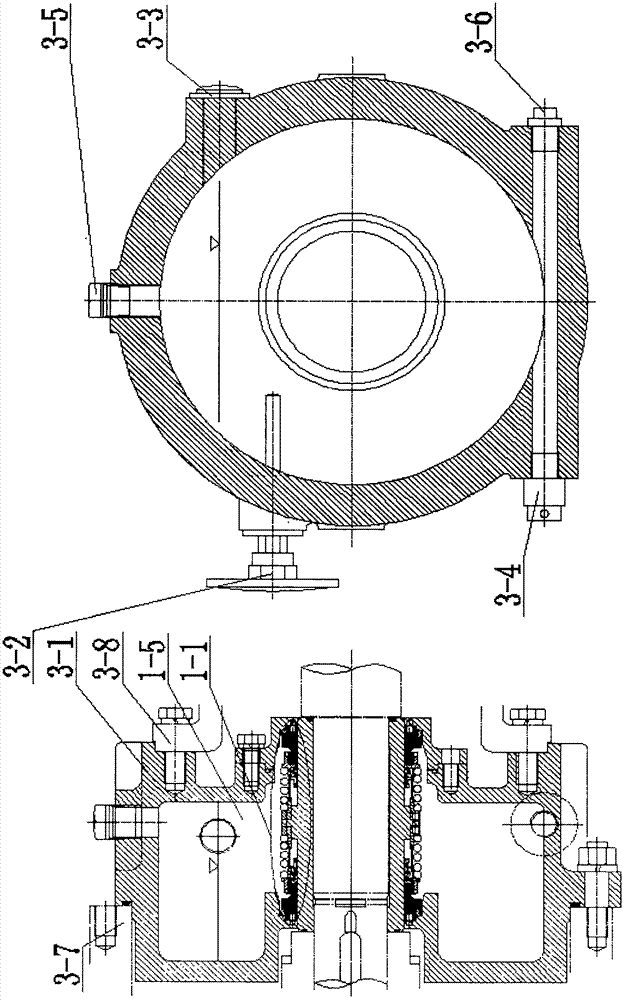

[0040] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described

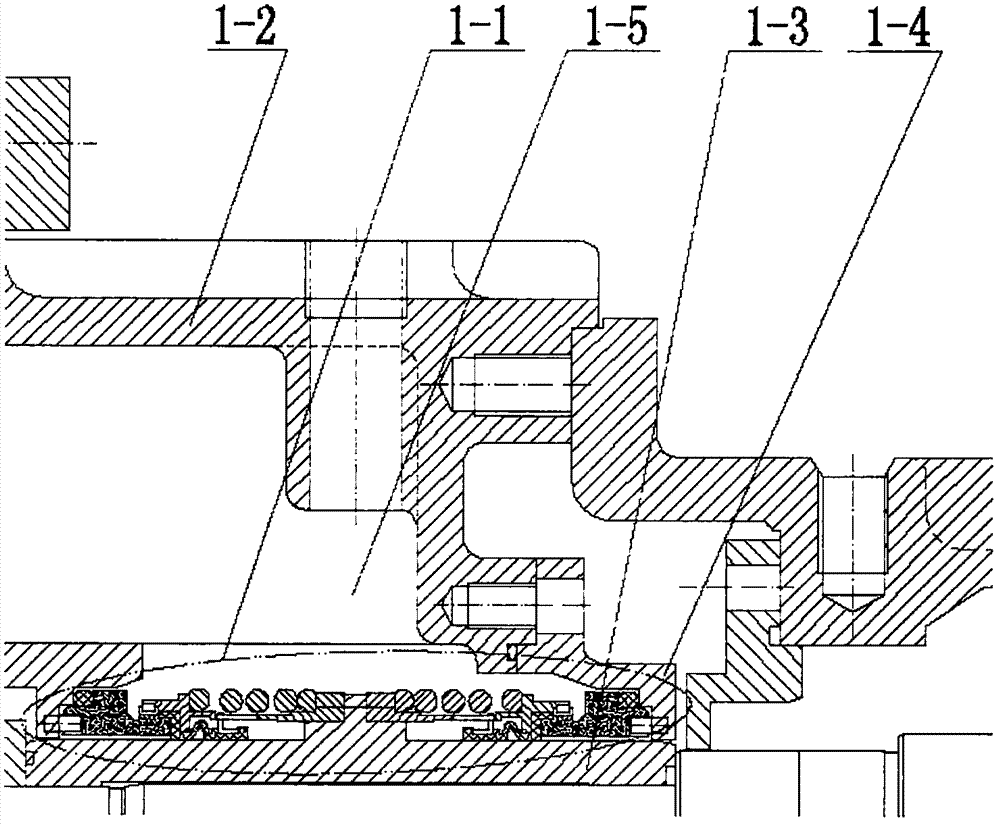

[0041] figure 1 Middle: The independent isolation and flushing system of the double-end mechanical seal for the centrifugal pump of plan 1, including the double-end mechanical seal 1-1, the isolation cavity assembly 1-2, the shaft sleeve 1-3 and the sealing gland 1-4, and the double-end mechanical seal The mechanical seal 1-1 is installed between the isolation cavity assembly 1-2 and the sealing gland 1-4, and is fixed on the shaft sleeve 1-3, and the spacer fluid 1-5 is filled between the three, and the double-end mechanical seal 1-1. Isolation chamber assembly 1-2, shaft sleeve 1-3 and sealing gland 1-4 can be assembled into a set of wearing parts, as a cartridge mechanical seal, without any adjustment, integral installation, convenient replace.

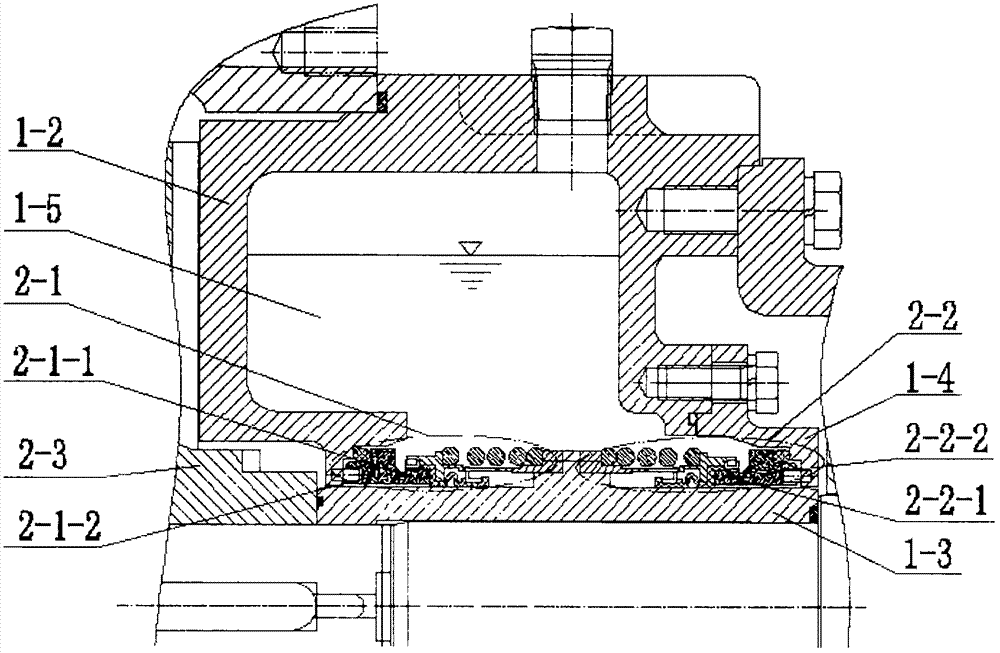

[0042] figure 2 Middle: The double-end mechanical seal 1-1 of plan 1 includes the first-level mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com