High-speed compost fermentation apparatus

A fermenter and composting technology, which is applied to organic fertilizers, photovoltaic power generation, fertilization devices, etc., can solve the problems of polluted air, inability to accurately measure the amount of feeding and discharge, and odor, and achieve the effect of improving fermentation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

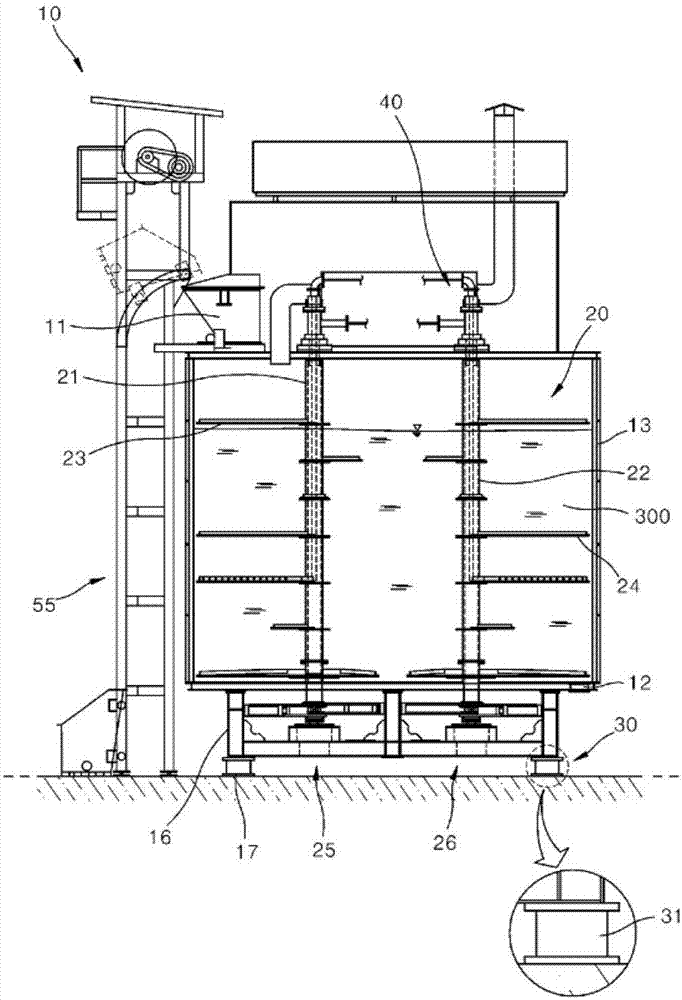

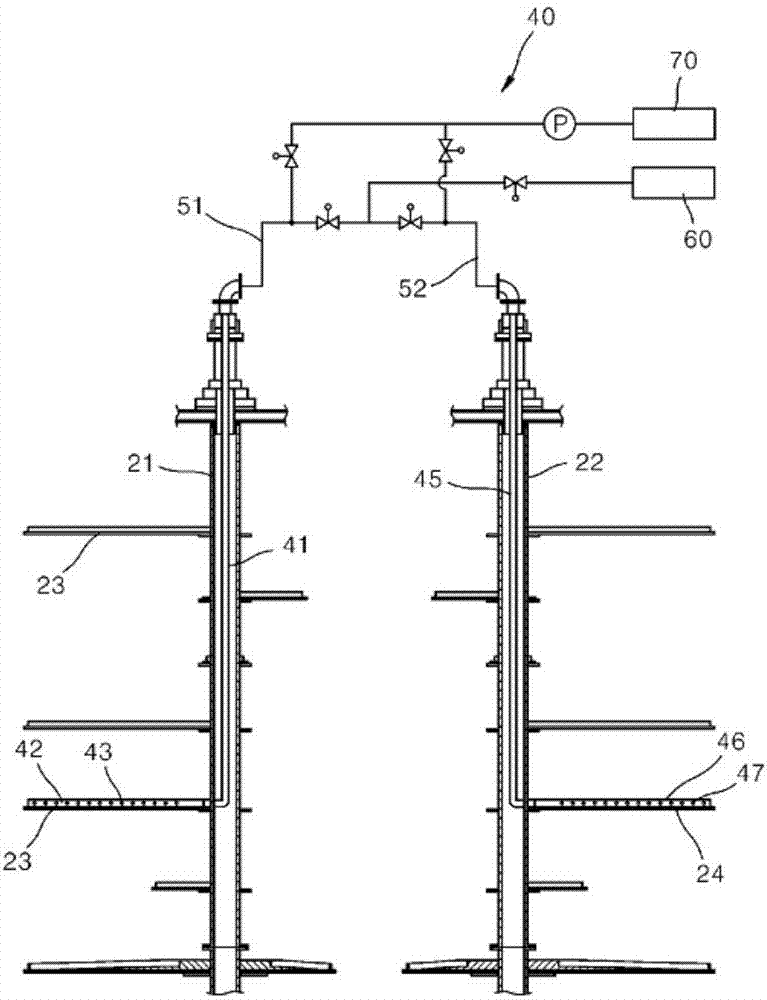

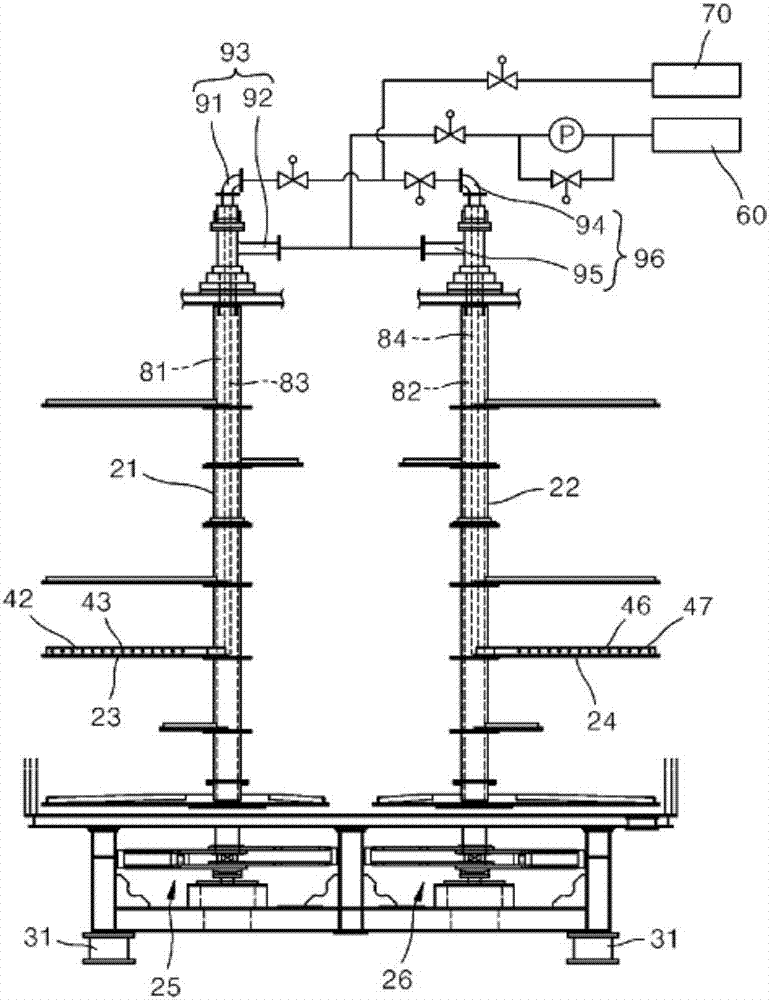

[0027] of the present invention Figure 1 to Figure 4 It shows that the high-speed composting fermenter can ferment food waste, livestock manure, animal and plant by-product organic industrial waste, etc. before composting.

[0028] Referring to the accompanying drawings, the high-speed composting fermenter 10 according to the present invention has a silo 13, a fermentation space is provided inside the silo, an input port 11 is provided on the upper side, and a discharge port 12 for discharging compost is formed on the lower side. An elevator 55 for dropping organic matter 300 into the feeding port 11 is provided on the outer peripheral surface of the silo 13 . A frame 16 for supporting the silo 13 is arranged at the lower part of the silo 13 , and the frame is arranged on a base member 17 .

[0029] The interior of the silo 13 and the frame 16 are provided with a stirring unit 20 for agitating the organic matter put into the interior of the silo 13, and a mixing unit 20 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com