Lined Butterfly Valve

A butterfly valve and lining type technology, which is applied in the direction of lifting valves, valve devices, mechanical equipment, etc., can solve the problems of secondary leakage, primary leakage, poor tightness, etc., and achieve the effect of improving shaft sealing and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

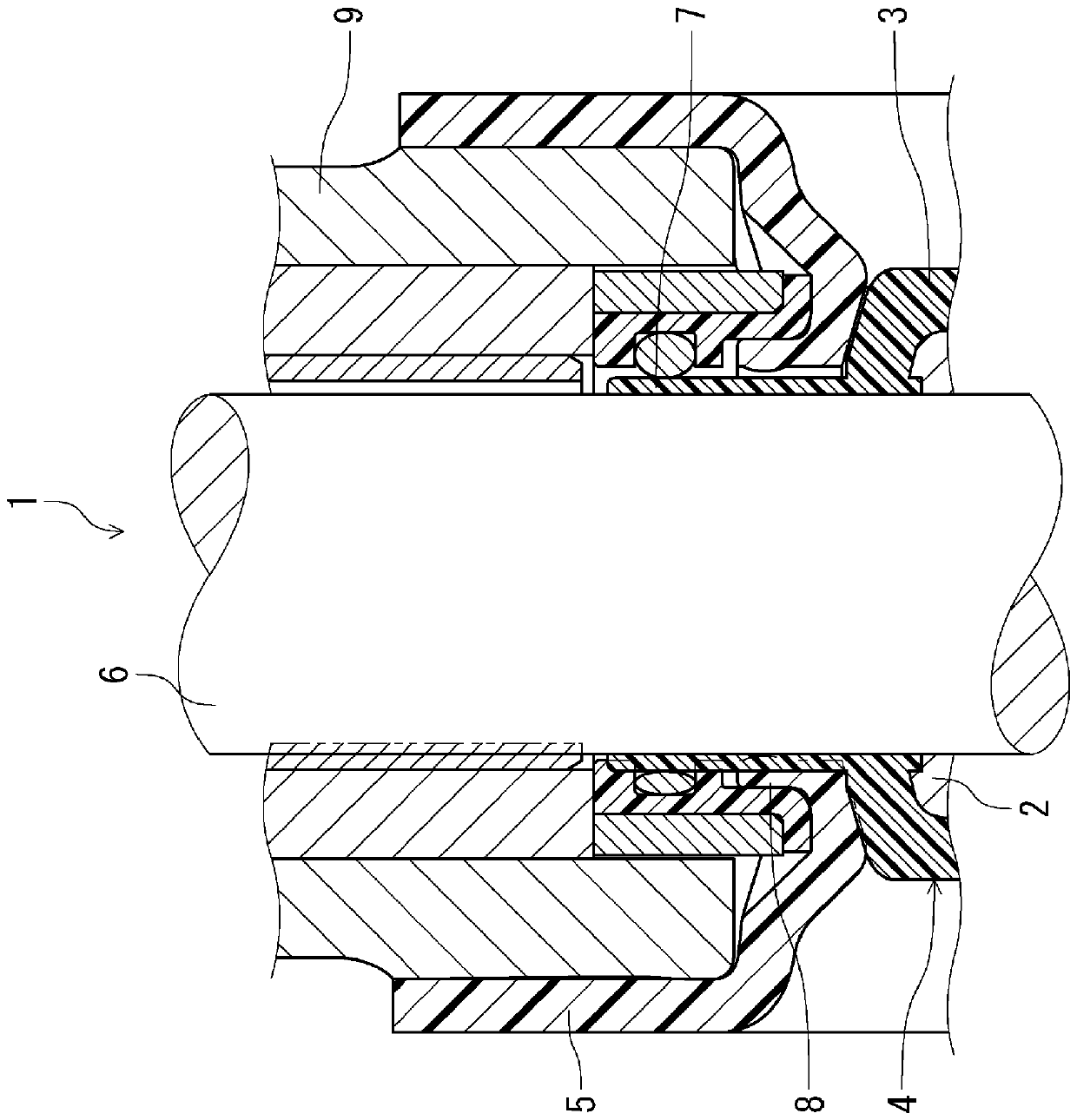

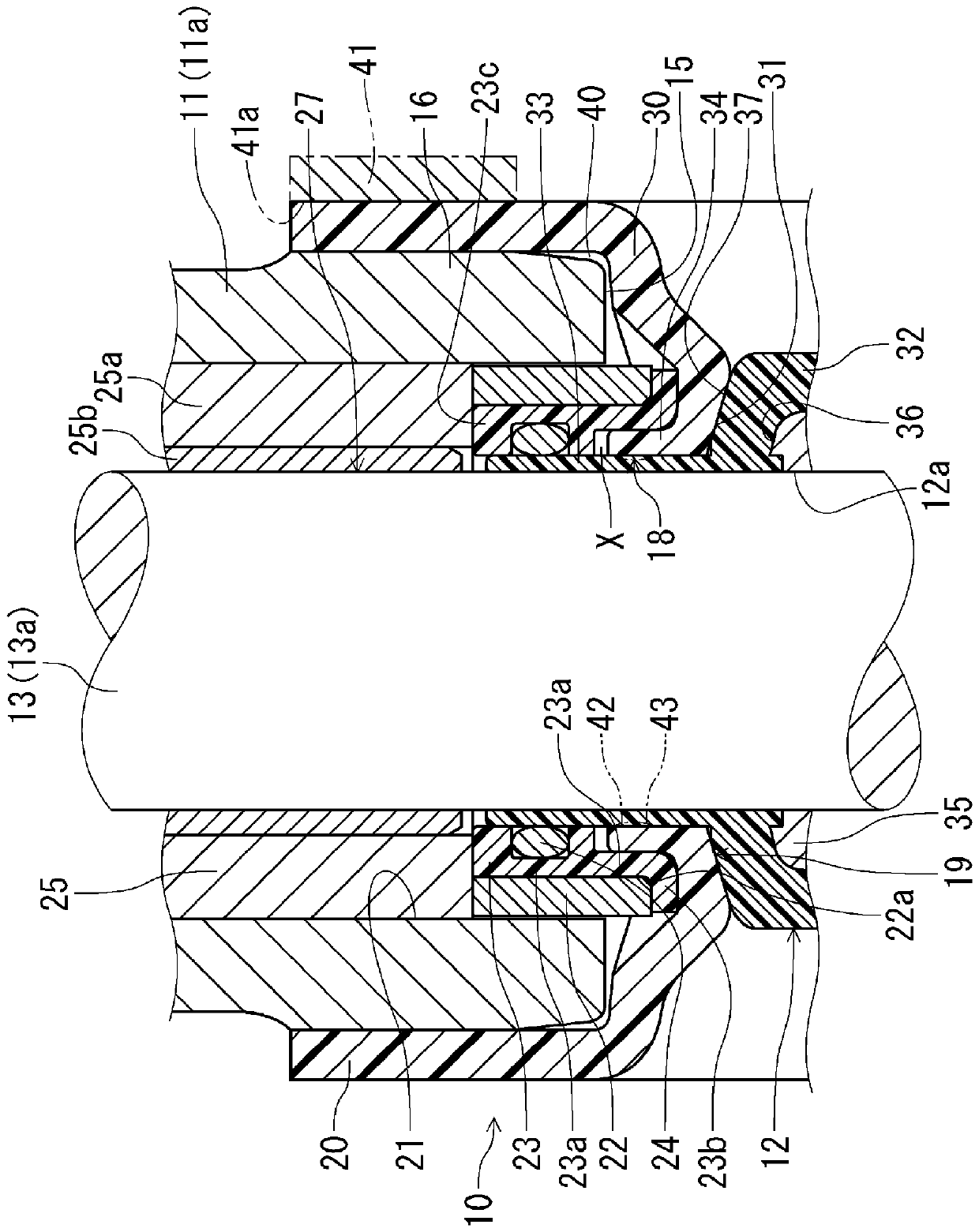

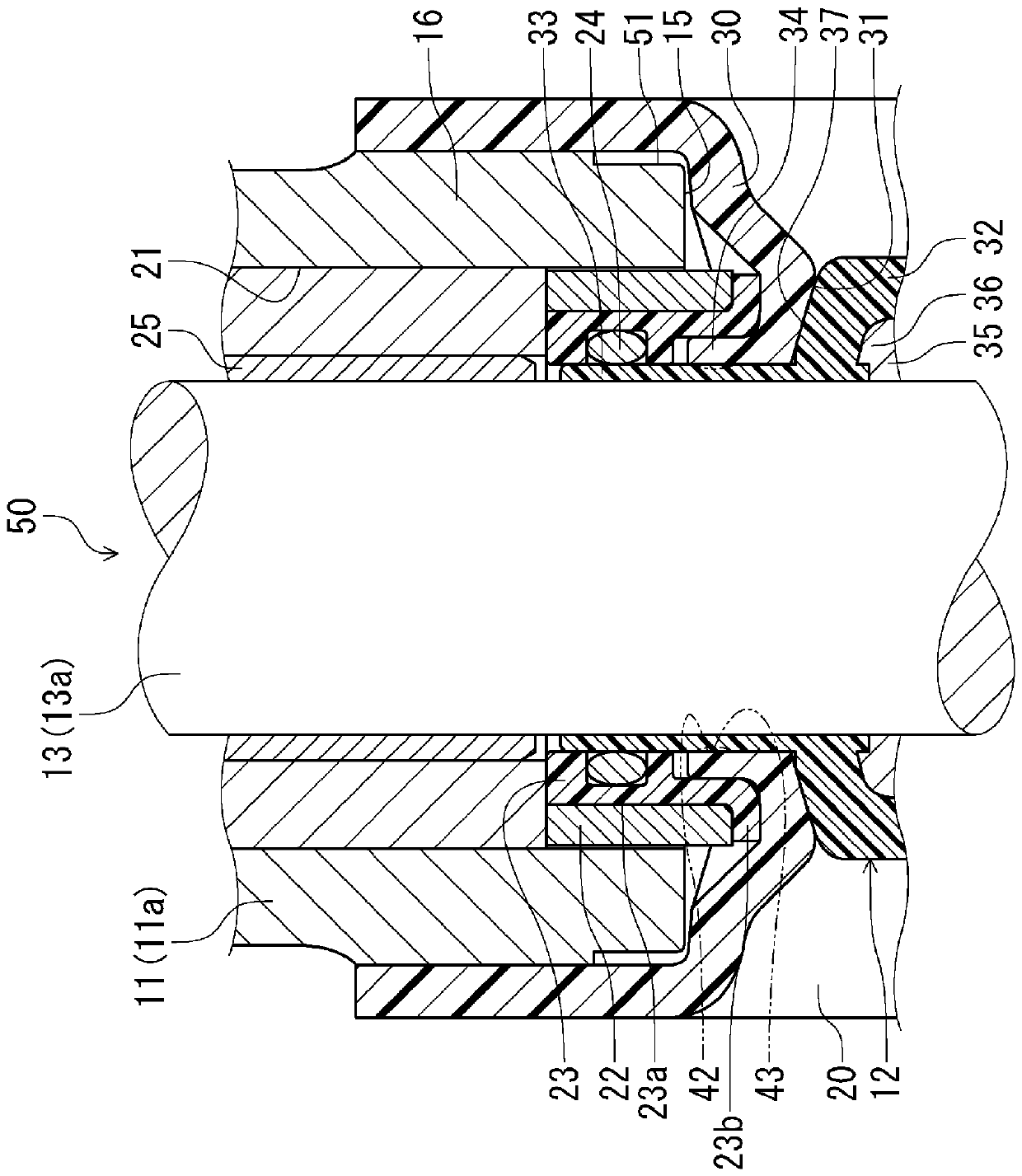

[0093] Hereinafter, embodiment of the liner type butterfly valve of this invention is demonstrated in detail based on drawing. exist figure 1 , figure 2 In, represents the embodiment of the butterfly valve of the present invention, in image 3 in, means figure 2 An enlarged sectional view of the main part.

[0094] exist figure 1 , figure 2Among them, the butterfly valve (hereinafter referred to as the valve body 10) is used, for example, in chemical industry facilities or food-related pipelines, and has a cylindrical valve body 11, a valve disc 12, an upper valve stem 13a and a lower valve body. The stem 13 constituted by the stem 13b is provided with a nominal diameter of 100A. As will be described later, in the valve main body 10, there are provided a cylindrical lining portion 34 having the valve seat lining 20, a shaft cylinder lining portion 33 of the lining portion 32, a shaft sealing portion 18 of the sealing bush 23, and a cylindrical lining portion 34 havi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap