Coating drying device and coating drying method

A drying device and coating technology, applied in the directions of drying gas arrangement, device for coating liquid on the surface, body drying, etc., can solve problems such as difficulty in meeting quality assurance standards, and difficulty in transferring hot air into the door, avoiding capacity increase, The effect of suppressing the decrease in thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

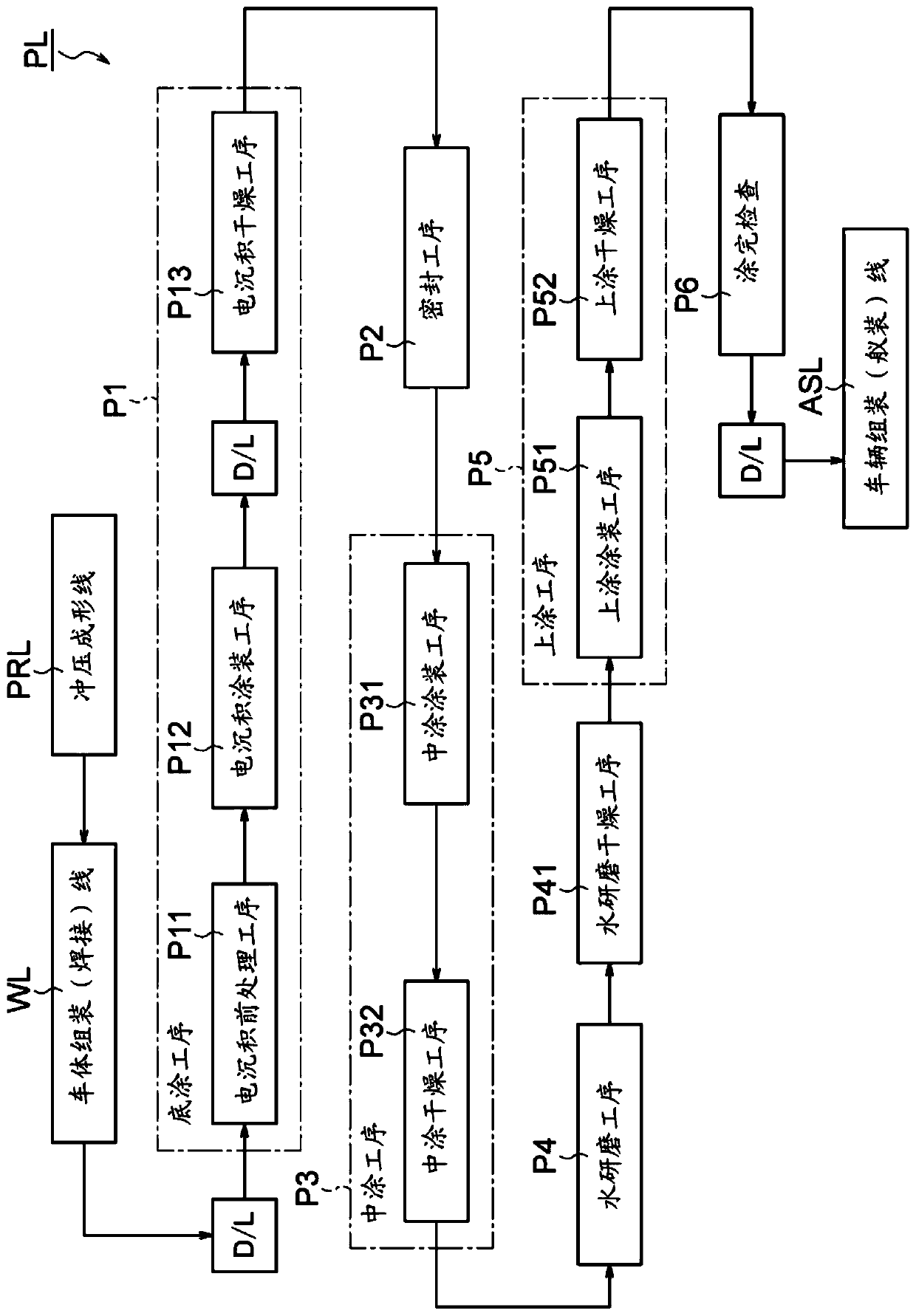

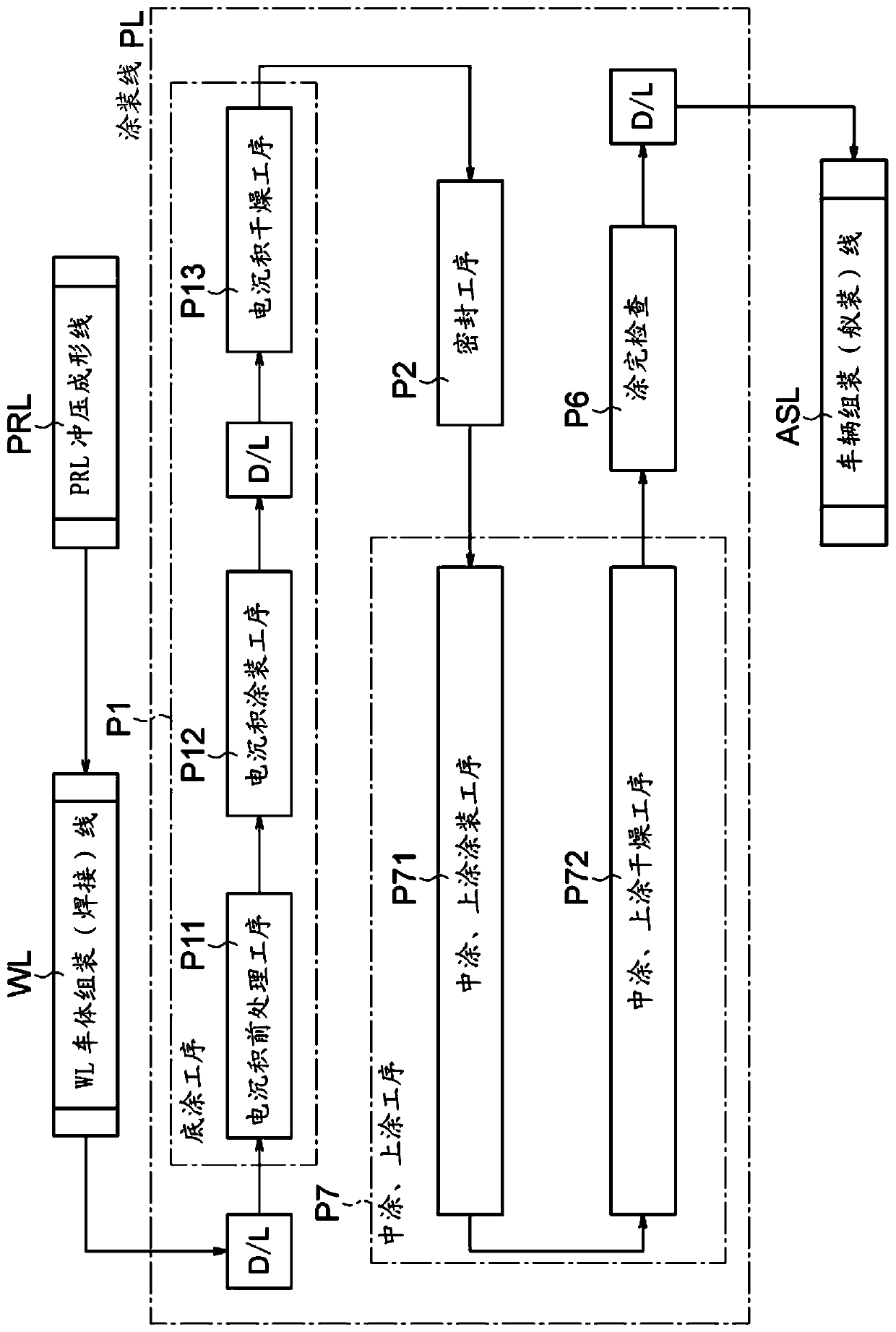

[0033] In the following embodiments, the best embodiment of the present invention will be described with an example of the top coating drying device 1 to which the coating drying device and coating drying method of the present invention are applied, but the coating drying device and coating drying device of the present invention The drying method can also be applied to an intermediate coating drying device, a primer coating drying device (electrodeposition coating drying device), or an intermediate coating and top coating drying device described later, in addition to the top coating drying device.

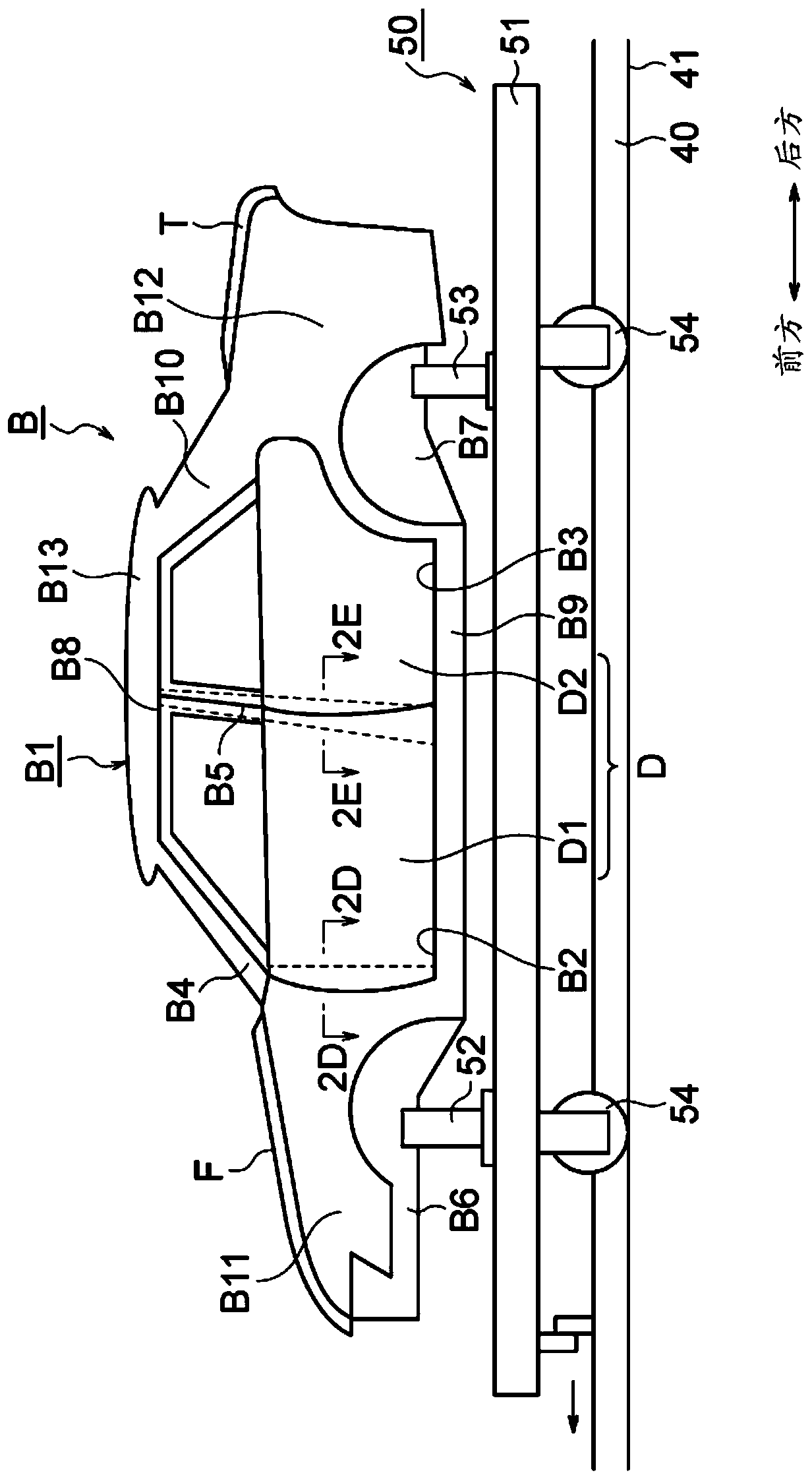

[0034] The top coating drying device 1 of the present embodiment is one of the devices constituting the painting line PL, and is used for transporting the body shell B (both referred to as automobile body B) mounted on the painting trolley 50, while using the A device for drying the top coating film applied to the automobile body B. In the following description, first, the outline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com