Contact element and equipping arrangement with the contact element

A technology of contact elements and equipment, applied in the field of contact elements of connectors, can solve problems such as difficulty, size reduction, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

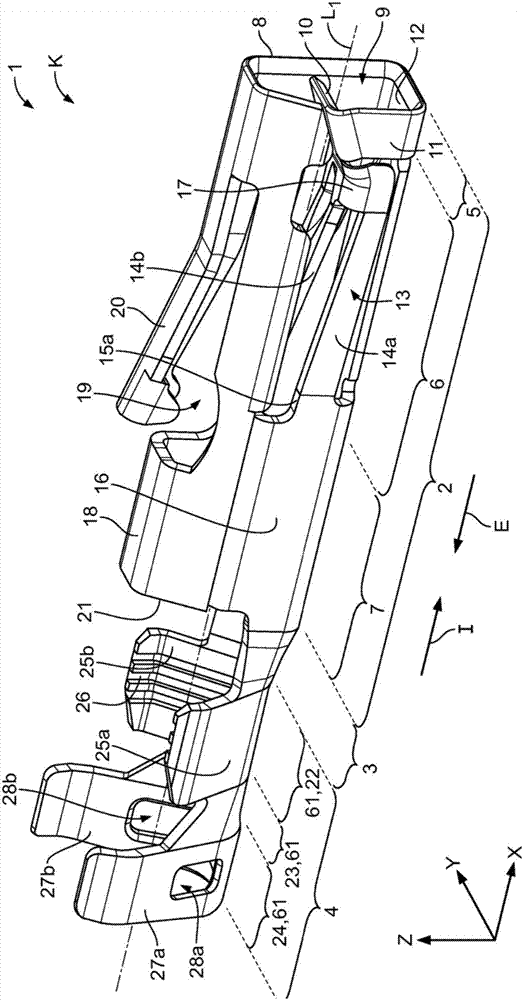

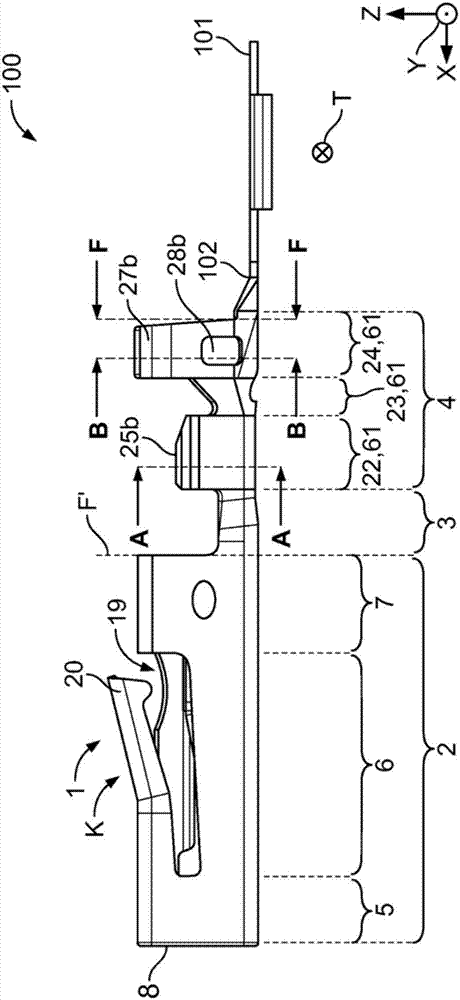

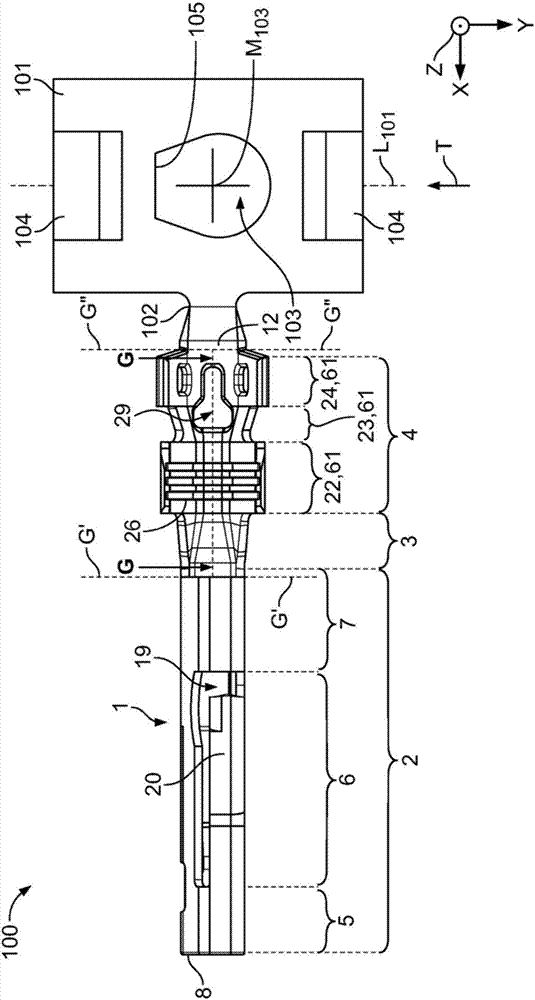

[0067] First, in figure 1 A possible embodiment of the contact element 1 according to the invention is described on the basis of, figure 1 A contact element 1 formed as a socket contact is shown in a schematic perspective view. Contact element 1 on its longitudinal axis L 1 in the longitudinal direction X, and transverse to the longitudinal axis L 1 Extends in the lateral direction Y and vertical direction Z. The longitudinal direction X, the transverse direction Y and the vertical direction Z collectively define a Cartesian coordinate system. All references below to front and rear generally relate to elements arranged or spaced relative to each other in or opposite to the longitudinal direction X. References to left or right generally relate to elements arranged or spaced relative to each other in the transverse direction Y. References to above and below generally relate to elements arranged or spaced relative to one another in or against the vertical direction Z.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com