Settling pool surface suspended matter sucking and filtering system

A technology for suspended solids and sedimentation. It is applied in the sedimentation tank, sedimentation separation, and the feeding/discharging device of the sedimentation tank. It can solve the problems of narrow application range and inflexible design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

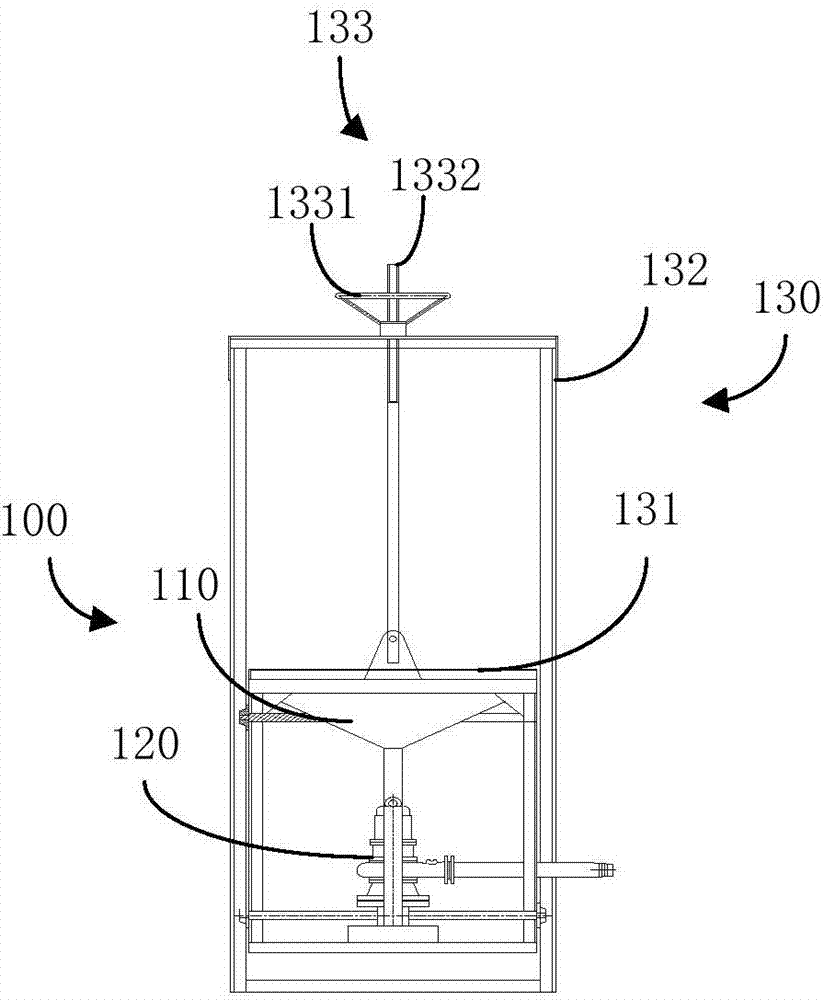

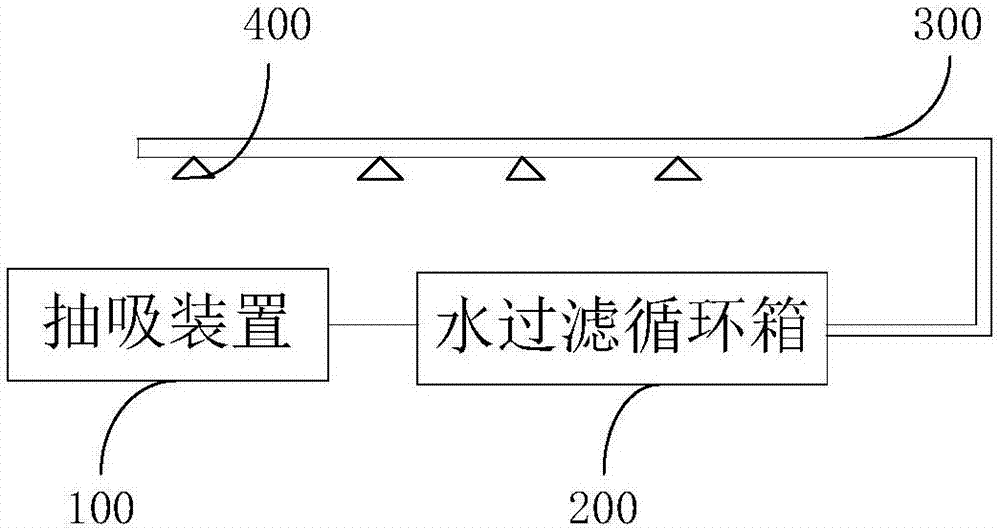

[0034] This embodiment provides a settling tank slag removal device, please refer to Figure 1 to Figure 4 , comprising: a suction device 100 connected by pipelines, a water filtration circulation box 200 and an auxiliary jet pipeline 300;

[0035] The suction device 100 is used to extract the water body in the settling tank and transport the water body to the water filtration circulation tank 200, the water body filtered by the water filtration circulation tank 200 flows into the auxiliary jet pipeline 300, and part of the water body in the auxiliary jet pipeline 300 is sprayed out , used to drive the scum on the surface of the sedimentation tank to flow to the suction device 100 .

[0036]In the sedimentation tank slag removal device in the present invention, in the starting state, the suction device 100 extracts the water body in the sedimentation tank and transports the water body to the water filtration circulation tank 200, and the water body extracted by the suction dev...

Embodiment 2

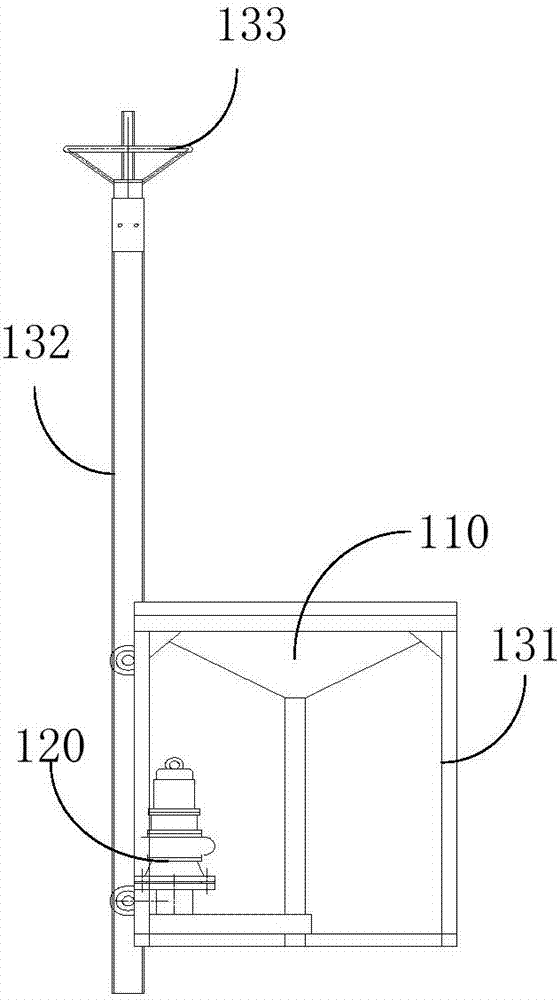

[0057] This embodiment provides a suction filtration system for suspended solids on the surface of a sedimentation tank, including the sedimentation tank slag removal device of Embodiment 1, and also includes a sedimentation tank, wherein the suction cup 110 of the suction device 100 and the submersible pump 120 are located below the water surface, the lower part of the second support frame 132 of the suction device 100 is located below the water surface, and the upper part extends to the upper edge of the settling tank. Preferably, the upper end of the suction device 100 is higher than the upper surface of the settling tank, more preferably Ground, the second support frame 132 leans against the settling tank, or is connected with the settling tank through other connecting parts, and the rotating disk 1331 of the adjusting part 133 is located above the second support frame 132, which can facilitate the operator to adjust the suction device 100. high.

[0058] In the sedimentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com