Energy-saving environment-friendly sewage treatment device used for cement plant

A sewage treatment device, energy-saving and environmental protection technology, applied in water/sludge/sewage treatment, water/sewage treatment, biological water/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

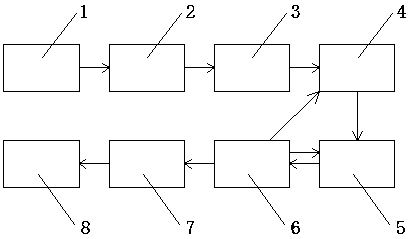

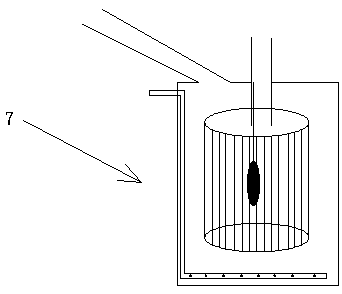

[0022] see Figure 1-6 , an energy-saving and environment-friendly sewage treatment device for a cement plant, including a water inlet pipe, and also includes a coarse filter tank 1, a fine filter tank 2, an anaerobic tank 3, a first anoxic tank 4, and a second anoxic tank 5 connected in sequence , aerobic pool 6, membrane pool 7 and outlet pipe 8, one end of the water inlet pipe is connected to the sewage pool, and the other end is connected to the coarse filter pool 1, and the aerobic pool 6 is respectively connected to the first anoxic pool 4 and the second anoxic pool through the return pipe 5 is connected, an aeration device is arranged under the membrane pool 7, a medicament bag is arranged inside the membrane pool 7, and the fine filter tank 2 and the anaerobic tank 3 are connected through a fine filter pipeline;

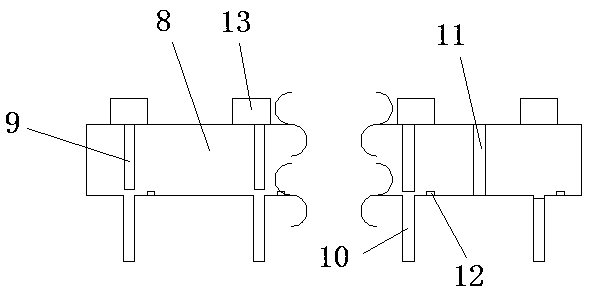

[0023] The outlet pipe 8 is arranged obliquely, and a plurality of electromagnets 13 are arranged at equal intervals above the outlet pipe 8. The aeration de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com