An in-situ activated fixed-bed heterogeneous catalyst reactor

A technology of heterogeneous catalysts and fixed bed catalysts, applied in chemical instruments and methods, chemical/physical processes, oxidized water/sewage treatment, etc., can solve the problems of reducing the power consumption of circulating water pumps, poor wastewater treatment effects, catalyst poisoning, etc. problems, to achieve the effect of improving anti-pollution, reducing power consumption, and good catalyst regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

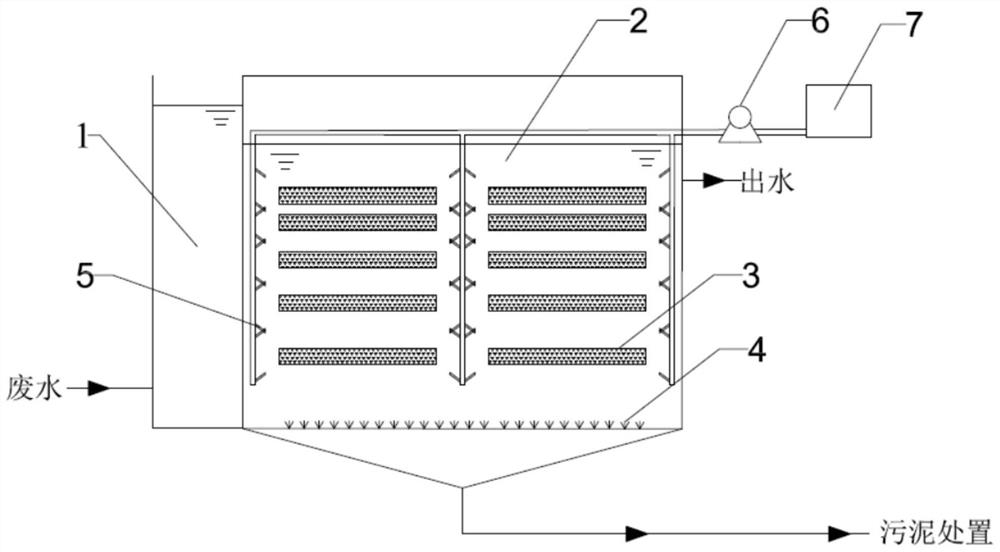

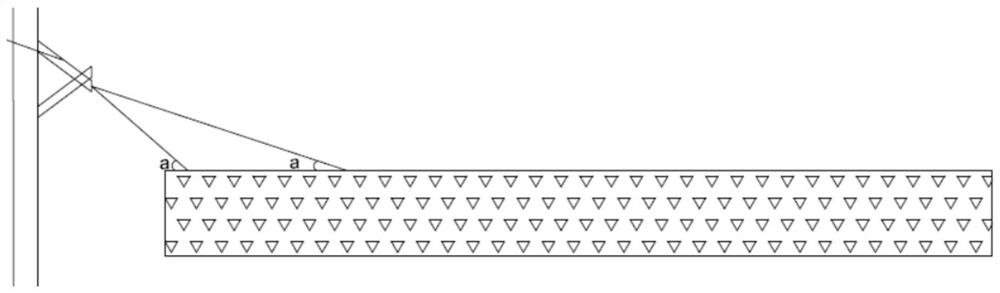

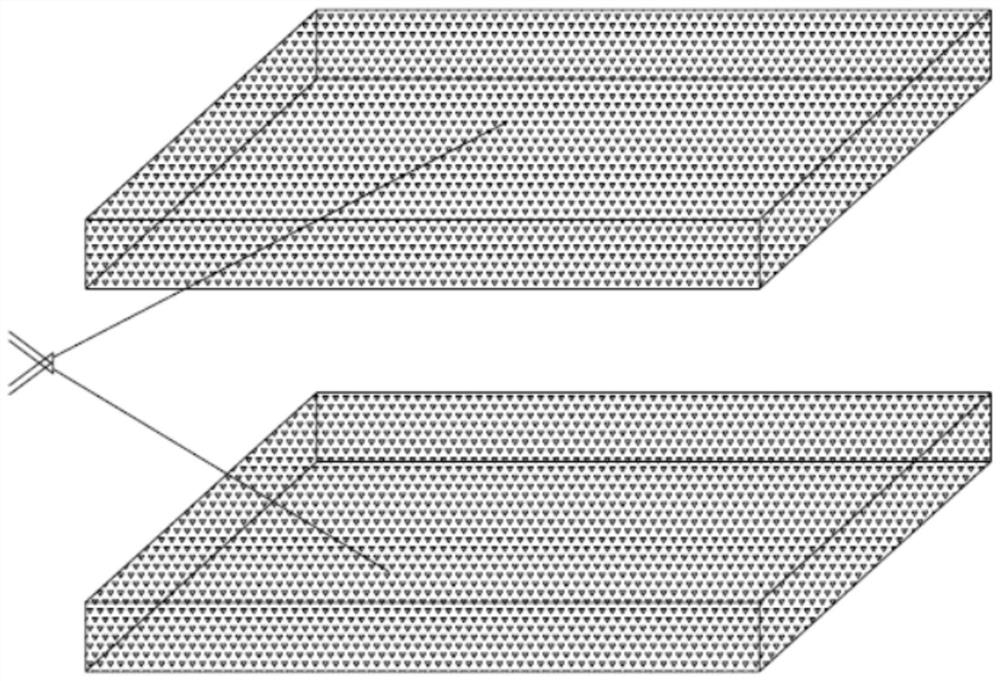

[0062]The in-situ activated fixed-bed heterogeneous catalyst reactor in this example is a Fenton-like catalytic reactor with an effective height of 4 m. The reactor is filled with fixed-bed catalysts. The catalysts are arranged in 4 layers and 2 columns. The height direction of the reactor gradually decreases from bottom to top. The distance between the two catalyst layers at the bottom of the reactor is 1 / 5 of the effective height of the reactor, that is, 0.8m. The distance between the two catalyst layers at the top of the reactor is 1 / 10 of the effective height of the reactor. , that is, 0.4m, the distance between the two catalyst layers in the middle is 0.6m, the catalyst layer height is 0.35m, and the catalyst filling height ratio is 35%. In the reactor, a circulating water pipe is installed around the catalyst and in the middle of the two rows. The circulating water pipe is connected to the circulating water tank through a circulating pump. A nozzle is installed on the cir...

Embodiment 2

[0071] The in-situ activated fixed-bed heterogeneous catalyst reactor in this example is an ozone catalytic oxidation tower, and the effective height of the reactor is 8m. The height direction gradually decreases from bottom to top, the distance between the two catalyst layers at the bottom of the reactor is 1 / 8 of the effective height of the reactor, that is, 1.0m, and the distance between the two catalyst layers at the top of the reactor is 1 / 20 of the effective height of the reactor, namely 0.4m, the distance between the middle two catalyst layers is 0.8m and 0.6m from bottom to top, the catalyst layer height is 0.4m, and the catalyst filling height ratio is 25%. In the reactor, a circulating water pipe is set around the catalyst, and the circulating water pipe is connected to the circulating water tank through a circulating pump. A nozzle is installed on the circulating water pipe, and the sprayed water flow of the nozzle plays a role in catalyst activation on the surface o...

Embodiment 3

[0075] The in-situ activated fixed-bed heterogeneous catalyst reactor in this example is a micro-electrolytic catalytic oxidation reactor, and the effective height of the reactor is 8m. The reactor is filled with fixed-bed catalyst iron-carbon packing, and the iron-carbon packing is divided into 3 layers and 2 columns. Arrangement, the distance between the catalyst layers and the height direction of the reactor gradually decreases from bottom to top. The distance between the two layers of catalyst layers at the bottom of the reactor is 1 / 4 of the effective height of the reactor, that is, 0.75m. The distance between the two layers of catalyst layers on the top of the reactor is the effective height of the reactor. 1 / 10 of the height, that is, 0.3m, the catalyst layer is 0.45m high, and the catalyst filling height ratio is 75%. In the reactor, a circulating water pipe is installed around the catalyst and in the middle of the two rows. The circulating water pipe is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com