Improved fully-automatic dosing machine

A fully automatic, batching machine technology, used in mixers, mixer accessories, essential oils/spices, etc., can solve the problems of complex calculation of the proportion of spices, high labor intensity, low efficiency, etc., to improve the quality of ingredients and product qualification rate, Improve the accuracy of ingredients and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the examples, and the contents mentioned in the embodiments are not intended to limit the present invention.

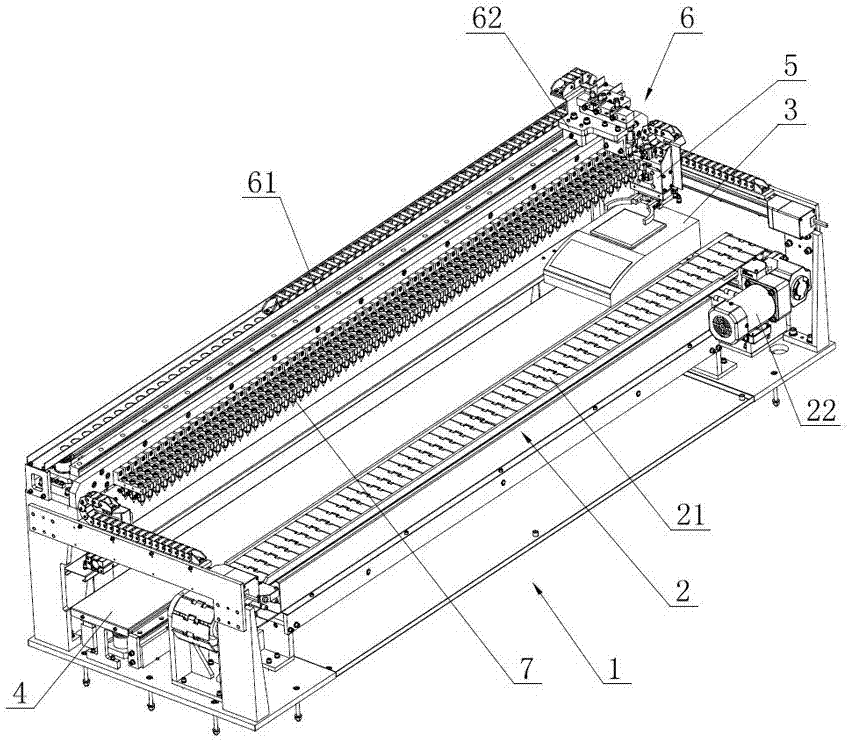

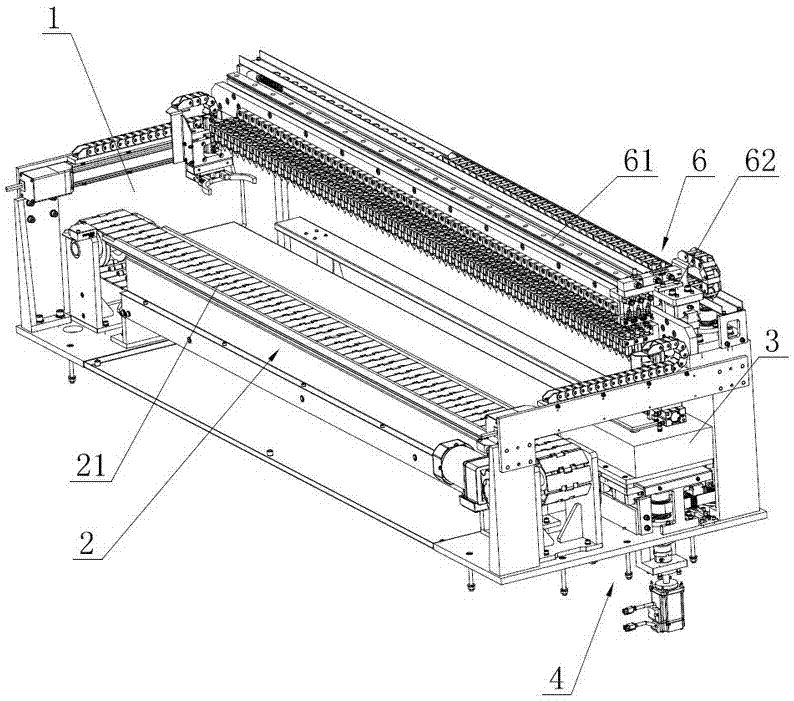

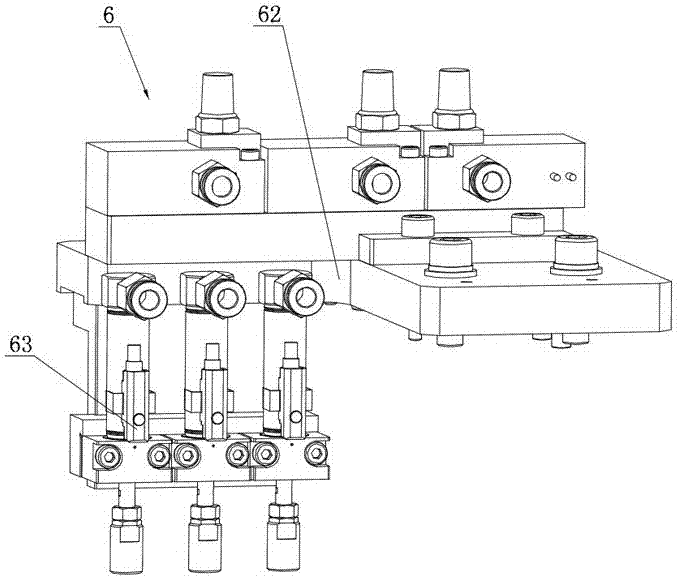

[0025] Such as Figure 1 to Figure 7 As shown, an improved fully automatic batching machine includes a frame 1, a container transfer device 2, a weighing device 3 and a feeding transfer device 4 for driving the weighing device 3 to move left and right. The side of the frame 1 is installed There is a loading and unloading manipulator 5 for transferring the container back and forth between the container transfer device 2 and the weighing device 3, the frame 1 is equipped with a head device 6 and a linear module 61 for driving the head device 6 to move left and right, The moving tracks of the head device 6 and the weighing device 3 are arranged parallel to each other on the frame 1; the top device of the weighing device 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com