Front wing plate support assembly mold

A plate bracket and assembly technology, which is applied in the mold field of the front wing plate bracket assembly, can solve the problems of low efficiency and large impact on precision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

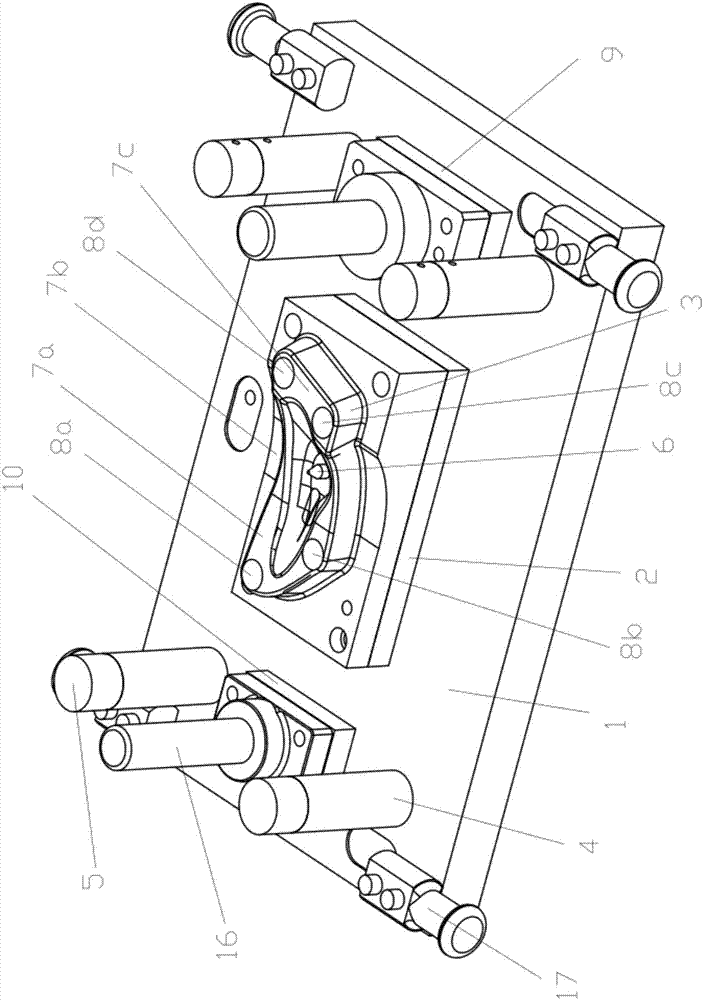

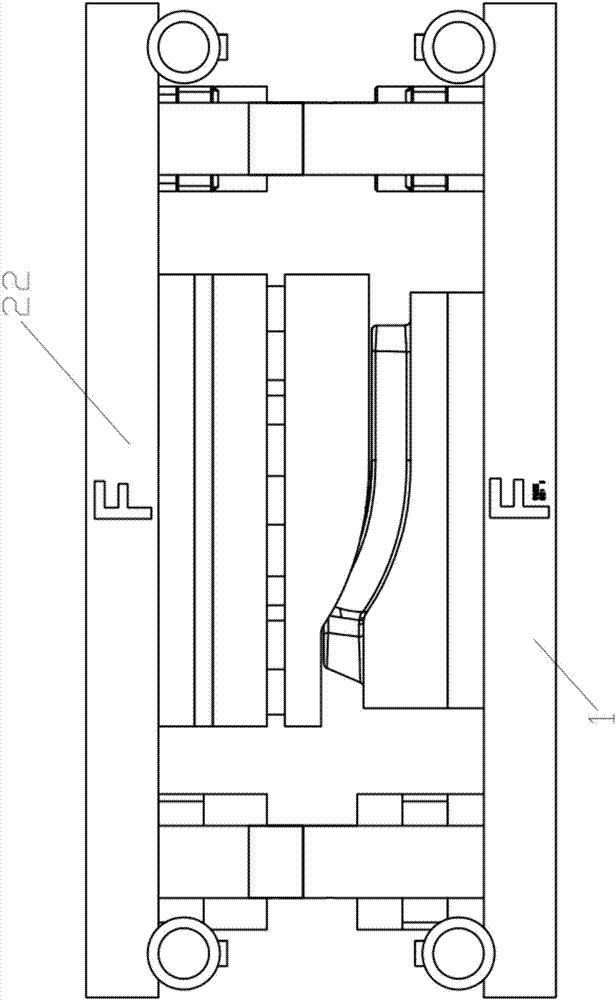

[0033] In order to achieve the purpose of the present invention, a front fender bracket assembly mold includes:

[0034] The lower mold core 3 has a first lower plane 7a and a second lower plane 7c with height differences, and the first lower plane 7a and the second lower plane 7c are connected by a lower curved surface 7b; the first lower plane 7a is equipped with a first punch The sleeve 8a and the second punch sleeve 8b, the third punch sleeve 8c and the fourth punch sleeve 8d are provided on the second lower plane 7c, the middle part of the lower mold core 3 has a depression, and the positioning guide pin 6 is arranged in the depression;

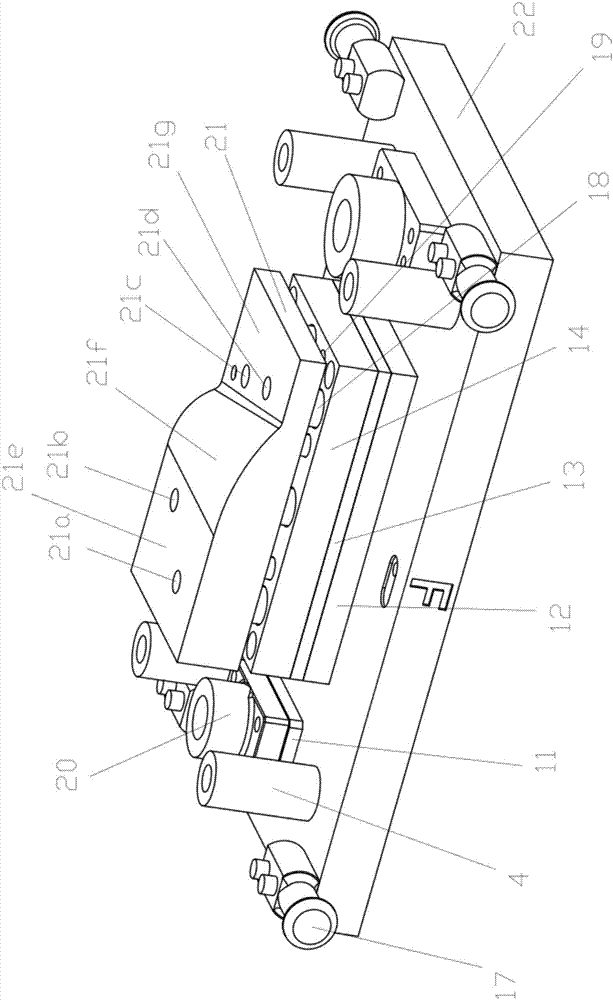

[0035] The upper binder plate 21 has a first upper plane 21e and a second upper plane 21g that match the drop between the first lower plane 7a and the second lower plane 7c, and the upper curved surface 21f is formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com