Automatic rubber pipe cutting off device

An automatic cutting and driving device technology, applied in the direction of transportation and packaging, metal processing, conveying filamentous materials, etc., can solve the problem that the rubber hose transportation and cutting work cannot be integrated, and the rubber hose cannot be quickly disassembled and replaced, and the rubber hose transportation Complicated device structure and other issues, to achieve the effect of simple structure, reduced manual monitoring, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

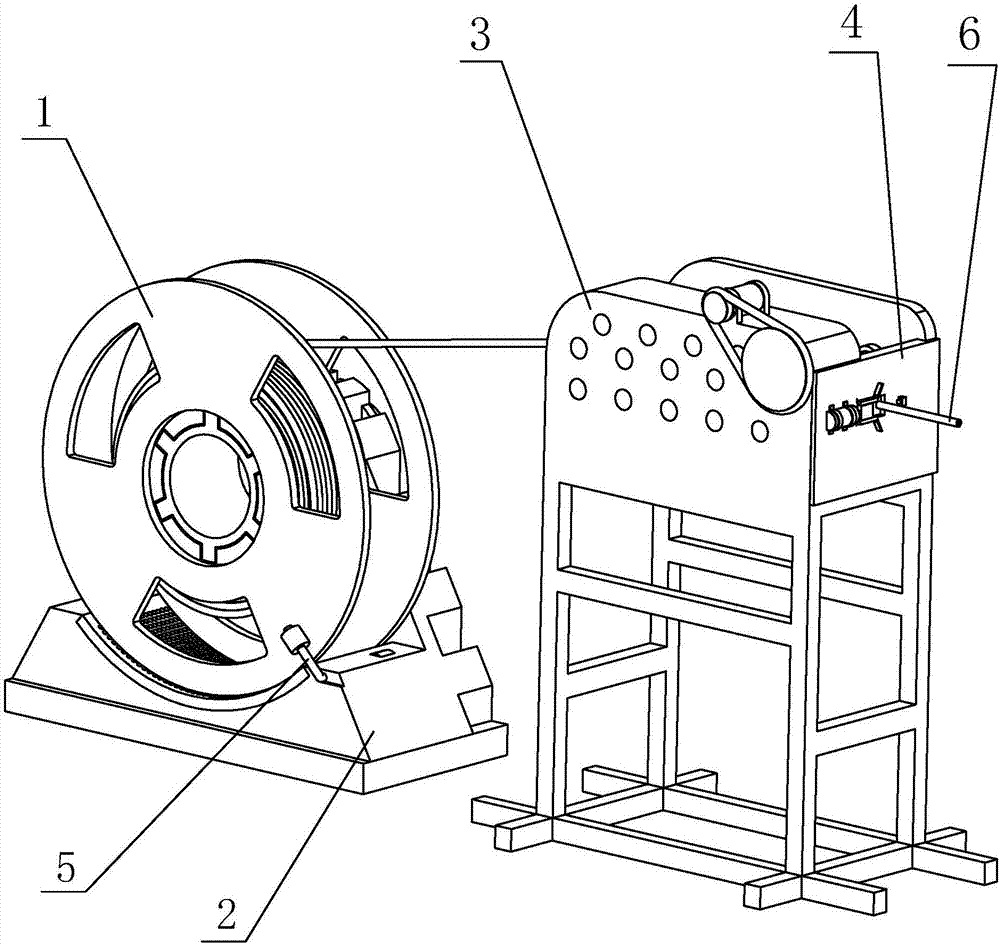

[0035] Such as figure 1 As shown, an automatic rubber hose cutting device includes a turntable device 1 , a rubber hose conveying device 3 and a rubber hose cutter 4 arranged in sequence.

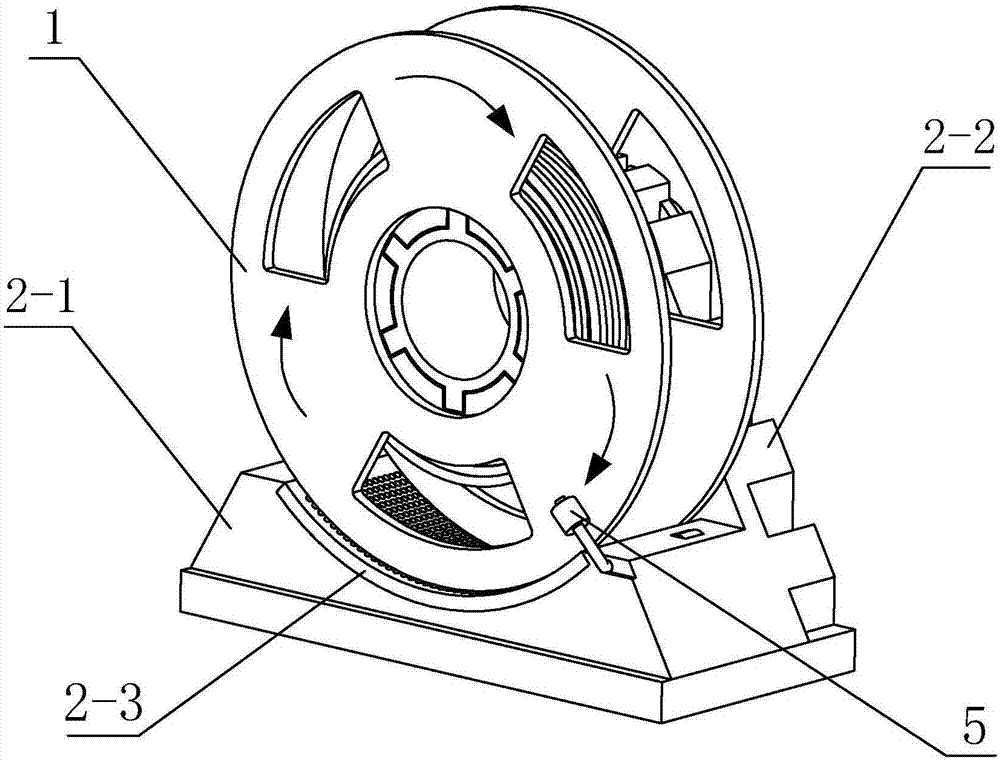

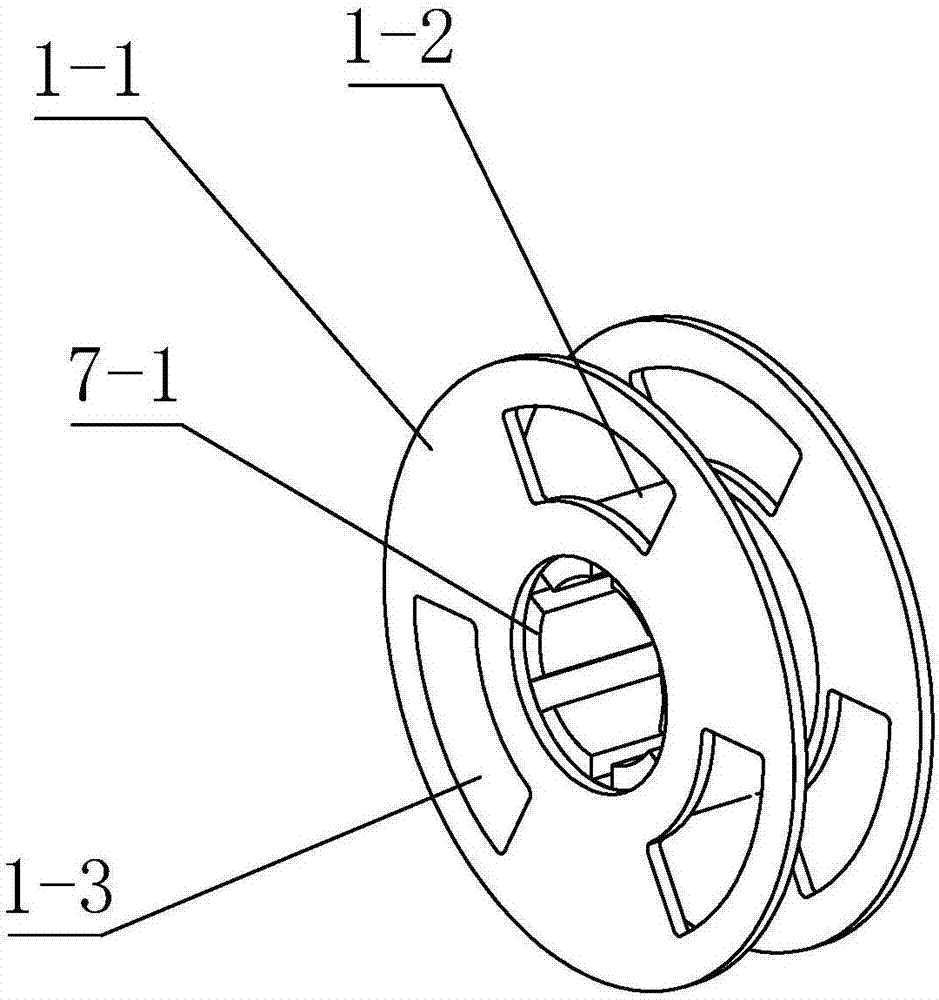

[0036] Such as figure 2 , Figure 4 As shown, the turntable device 1 includes a turntable, a stopper 5, a turntable driver 8 and a turntable mount 2 for installing the turntable. The turntable mounting seat 2 includes a base 2-1 and a side seat 2-2 vertically installed on the base 2-1, the upper end of the side seat 2-2 is provided with a turntable shaft 9, and the turntable is connected by a spline coupling. Installed on the turntable shaft 9. The turntable driver 8 is arranged on the side seat 2-2 and connected with the turntable shaft 9. The turntable driver 8 may specifically be a variable frequency motor. The limiter 5 is installed on one end of the base 2-1, and forms a limit space with the side seat 2-2 for limiting the left and right displacement of the turntable.

[0037] An a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com